ENGINE

3.44

TENSIONER BLADE

INSTALLA

TION

1. Install the tensioner blade and tighten the

mounting bolt to specified torque.

Tensioner Blade Mounting Bolt Torque:

6 ft. lbs. (8 Nm)

PISTON RING INSTALLATION

NOTE: Apply clean engine oil to allring surfaces and

ring lands. Always check piston ring installed gap

before rings are installed on piston. See Page 3.30.

If the piston has been in service clean any

accumulated carbon from the ring grooves and oil

control ring holes.

1. Place the oil control ring expander in oil ring

groove with the end gap facing forward. The

expander has no up or down marking and can be

installed either way. The ends should butt

squarely together and must not overlap.

2. Install the oil ring top rail.

NOTE: The top rail has a locating tab to prevent

rotation. The tab must be positioned in the notch on

the side of the piston as shown (A).

A

3. Install the bottom rail with the gap at least 30°

from the end of the expander on the side opposite

the top rail gap.(See ILL. 1).

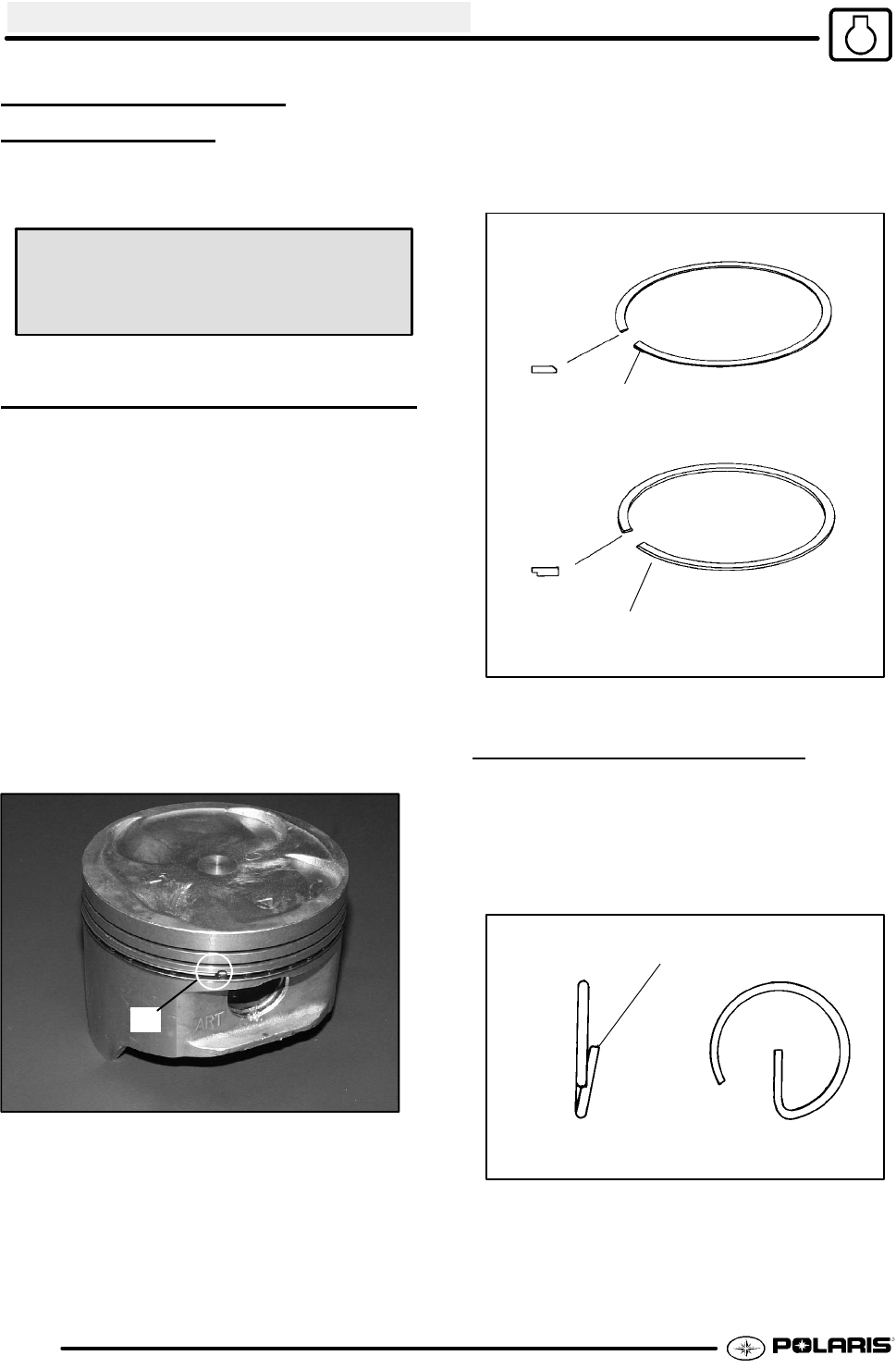

4. Install the second ring with the “R” mark facing up.

Position the end gap toward the rear (intake) side

of the piston.

5. Install the top ring (chrome faced) with the “R”

mark facing up and the end gap facing forward

(toward the exhaust). (See ILL. 1).

6. Check to make sure the rings rotate freely in the

groove when

compressed.

Ring Profile

Top

Mark up

Mark up

Second

ILL. 1

PISTON INSTALLATION

1. Clean the gasket surfaces on the cylinder and

crankcase. Remove all traces of old gasket

material.

2. Make sure the cylinder mounting bolt holes are

clean and free of debris.

Tang Outward

3. Install a new circlip on one side of the piston with

the end gap facing up or down, and tang outward.

CAUTION: Circlips become deformed during the

removal process. Do not re-use old circlips. Do not