ENGINE

3.33

2. Remove blade and inspect for cracks, wear, or

damage.

B

3. Remove cam chain (B). Inspect chain for worn or

missing rollers or damage. Stretch chain tight on

a flat surface and apply a 10 lb. (4.53 kg) load.

Measure length of a 20 pitch section of chain.

Replace if worn past service limit.

Chain Service Limit:

5.407″ (13.7 cm)

4. Using the special socket, remove the crankshaft

slotted nut (A). NOTE: The slotted nut is a left

hand thread.

5. Remove cam chain drive sprocket (B) and

Woodruff key from crankshaft.

6. Inspect sprocket teeth for wear or damage.

7. Inspect Woodruff key for wear.

8. Replace any worn or damaged parts.

ONE WAY VALVE

The one way valve prevents oilfrom draining out of the

oil tank and into the crankcase when the engine is off.

It must be clean and have adequate spring pressure

in order to seal properly.

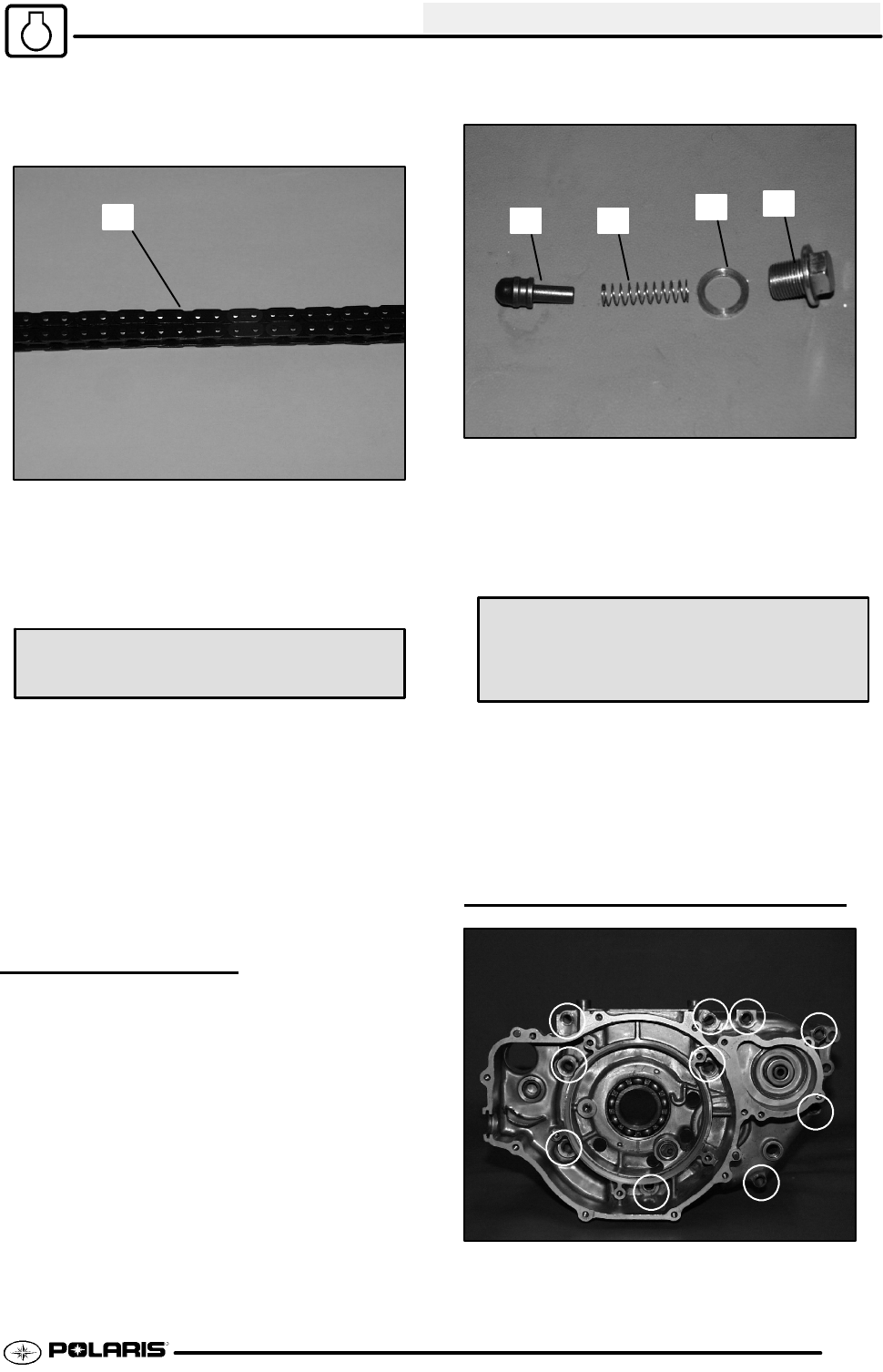

B

CD

A

1. Remove cap bolt (A), sealing washer (B), spring

(C), and one way valve (D) from PTO side

crankcase.

2. Inspect free length of spring and check coils for

distortion.

One Way Valve Spring Free Length:

Std: 1.450″ (3.68 cm)

3. Inspect valve for wear.

4. Check seat area for nicks or foreign material that

may prevent proper sealing of valve.

CRANKCASE SEPARATION

1. Remove flange bolts (10) from magneto side

crankcase evenly in a criss-cross pattern.