ENGINE

3.26

A

18. Clean cylinder head, valves, and camshaft oil

supply passage (A) thoroughly.

19. If oil passage blind plug was removed, apply

Crankcase Sealant (PN 2871557) or equivalent

sealer to the threads and install, torquing to 8 ft.

lbs. (11 Nm). CAUTION: Do not allow sealant to

enter oil passage.

20. Spray electrical contact cleaner into oil passage

and dry using compressed air.

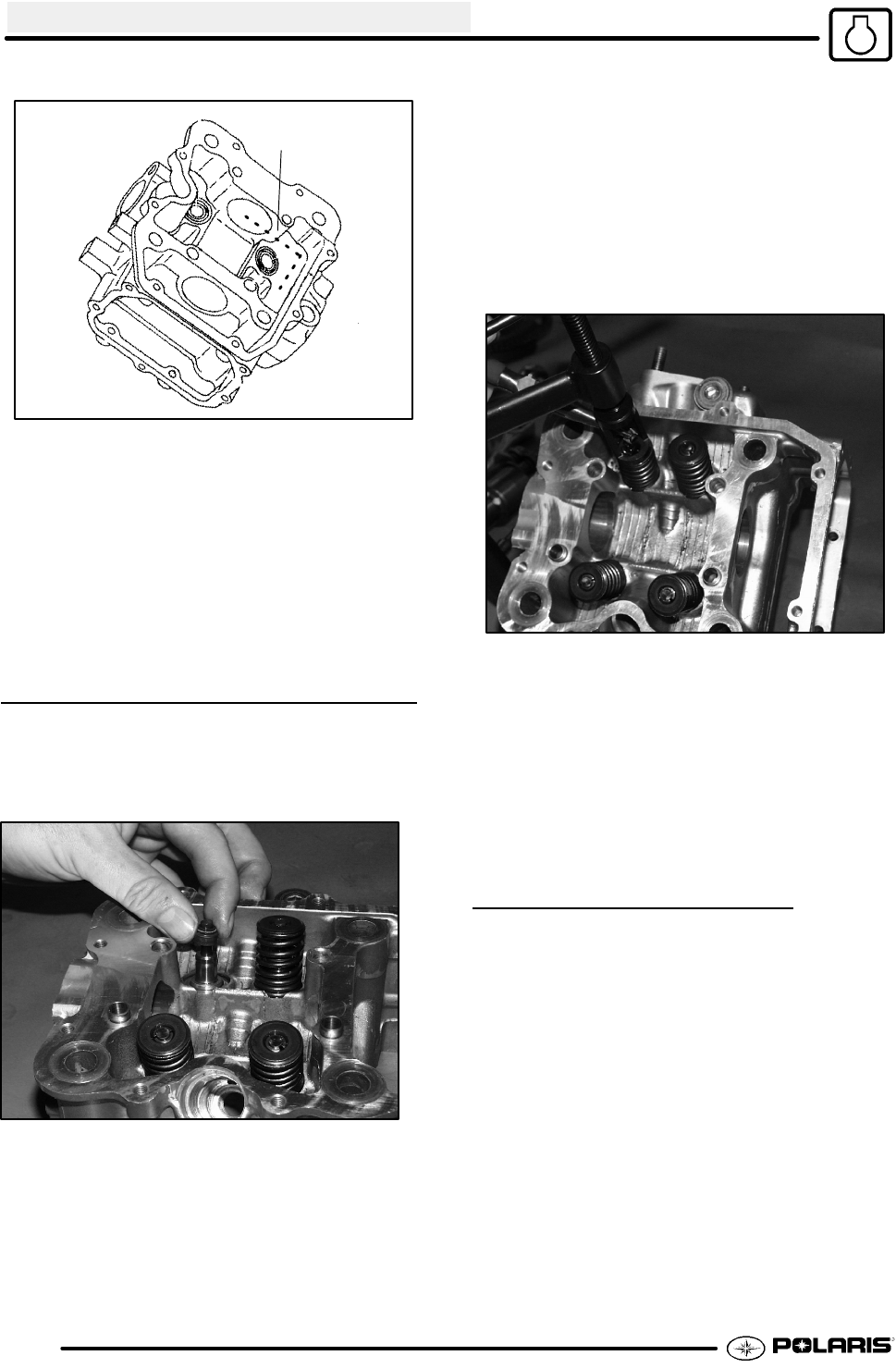

CYLINDER HEAD ASSEMBLY

CAUTION: Wear eye protection during assembly.

NOTE: Assemble the valves one at a time to

maintain proper order.

1. Install new valve seals on valve guides.

2. Apply engine oil to valve guides and seats.

3. Coat valve stem with molybdenum disulfide

grease.

4. Install valve carefully with a rotating motion to

avoid damaging valve seal.

5. Dip valve spring and retainer in clean engine oil

and install spring with closely spaced coils toward

the cylinder head.

6. Place retainer on spring and install valve spring

compressor. Compress spring only enough to

allow split keeper installation to prevent loss of

spring tension. Install split keepers with the gap

even on both sides.

7. Repeat procedure for remaining valve.

8. When all valves are installed, tap lightly with soft

faced hammer onthe end of the valves to seat the

split keepers.

VALVE SEALING TEST

1. Clean and dry the combustion chamber area.

2. Pour a small amount of clean, high flash point

solvent into the intake port and check for leakage

around each intake valve. The valve seats should

hold fluid with no seepage.

3. Repeat for exhaust valves by pouring fluid into

exhaust port.