ELECTRICAL

10.22

Alternator Current Output Reading should be no

less than 30--40V AC above 2000 RPM on each

’leg’.

NOTE: If one or more of the stator leg output AC

voltage varies significantly from the specified value,

the stator may need to be replaced.

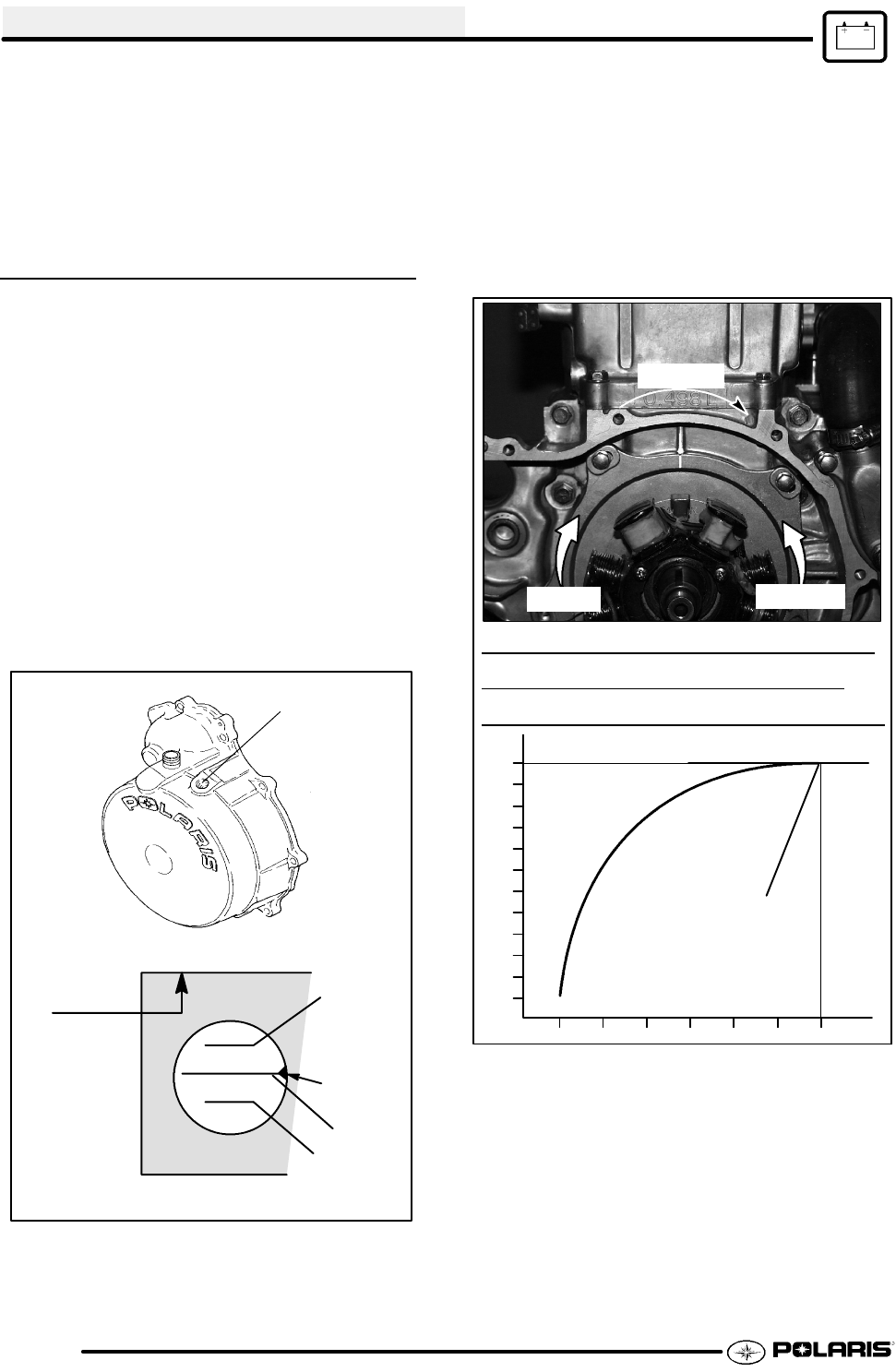

TIMING CHECK PROCEDURE

1. The ignition timing check hole is in the starter

recoil/magneto housing. Remove the check plug.

*NOTE: NOTE: The ignition timing marks are

stamped on the outside of the flywheel. Ignition timing

must be inspected with the engine at room

temperature (68°F/20° C).

2. With the transmission in neutral, start the engine

and set engine speed to 5000 ± 200 RPM.

3. Direct the timing light at the ignition timing check

hole and check the ignition timing. NOTE: Do not

allow the engine to warm up. The timing will retard

approximately 2° when the engine is warm.

If the ignition timing is not within the specified range,

adjust the stator plate position as described below.

Flywheel

Rotation

32

Timing

Pointer

30

28

EH50PL 30° BTDC @5000 RPM

Timing

Inspec-

tion

Hole

Stator Adjustment

1. Remove the magneto housing.

2. Remove the flywheel.

3. Loosen the stator plate screws and adjust the

stator plate position. NOTE: Moving the stator

plate clockwise retards (delays) the ignition

timing. Moving the plate counterclockwise

advances it.

8

10

12

14

16

18

20

22

24

26

28

30

IGNITION TIMING (DEGREES) B.T.D.C.

MAXIMUMADVANCE POINT (*)

0 1000 2500 3000 3500 4000 4500 5000

TYPICAL IGNITION TIMING CURVE * ACTUAL ADVANCE POINT

MAYVARY BY SEVERALHUNDRED RPM ABOVE OR BELOW 5000

.

USE THE POINT OF MAXIMUM ADVANCE WHEN CHECKING IGNITION

TIMIN

Retard

Advance

Rotation