ENGINE

3.24

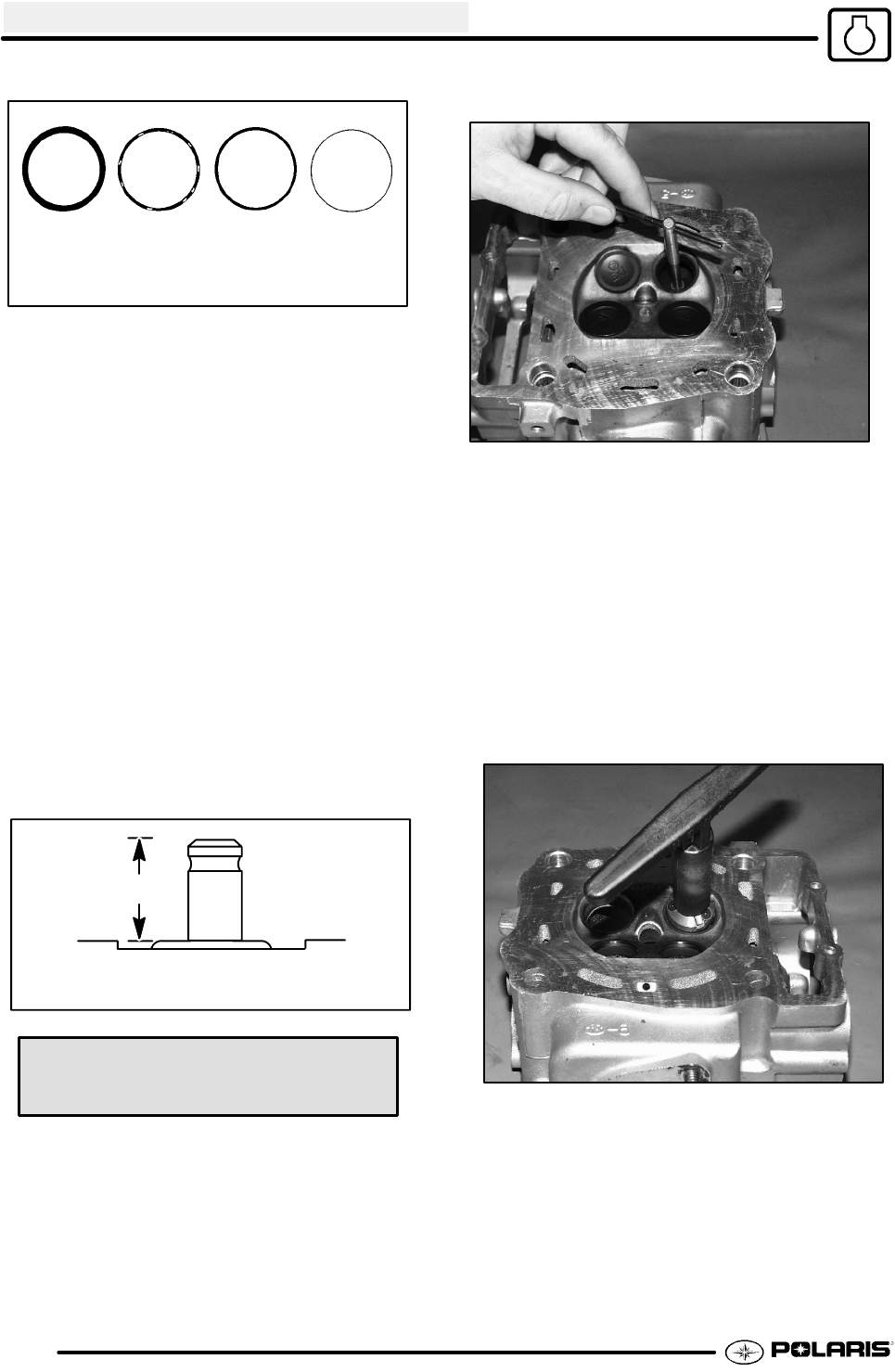

Too

Wide

Uneven

Good

Too

Narrow

NOTE: Valve seat width and point of contact on the

valve face is very important for proper sealing. The

valve must contact the valve seat over the entire

circumference of the seat, and the seat must be the

proper width all the way around. If the seat is uneven,

compression leakage will result. If the seat is too

wide, seat pressure is reduced, causing carbon

accumulation and possible compression loss. If the

seat is too narrow, heat transfer from valve to seat is

reduced and the valve may overheat and warp,

resulting in burnt valves.

1. When thoroughly heated, place cylinder head on

blocks of wood which will allow the old guides to

be removed.

2. Using valve guide driver, drive guides out of the

cylinder head from the combustion chamber side.

Be careful not to damage guide bore or valve seat

when removing guides.

3. Place cylinder head on cylinder head table.

NOTE: Be sure cylinder head is still at 212° F

(100° C) before installing new guides.

A

Valve Guide Installed Height

Valve Guide Height:

.689-.709I (17.5-18.0 mm)

4. Place a new guide in the valve guide installation

tool and press guide in to proper depth. Check

height of each guide above the cylinder head (A).

NOTE: Theguidecanalsobedrivenintothe

proper depth. Inspect the guideclosely for cracks

or damage if a driver is used.

Reaming The Valve Guide

5. Allow cylinder head to cool to room temperature.

Apply cutting oil to the reamer. Guides should be

reamed from the valve spring side of the cylinder

head. Ream each guide to size by turning the

reamer clockwise continually. Continue to rotate

reamer clockwise during removal of the tool.

6. Cleanguides thoroughly with hot soapy water and

a nylon brush. Rinse and dry with compressed

air. Apply clean engine oil to guides.

7. Install pilot into valve guide.

8. Apply cutting oil to valve seat and cutter.

9. Place 46° cutter on the pilot and make a light cut.

10. Inspect the cut area of the seat.

S If the contact area is less than 75% of the

circumference of the seat, rotate the pilot

180° and make another light cut.

S If the cutter now contacts the uncut

portion of the seat, check the pilot. Look

for burrs, nicks, or runout. If the pilot is

bent it must be replaced.