CLUTCHING

6.29

E

5. Inspect surface of rollers for flat spots and wear.

Rollers must rotate freely on pins without

excessive clearance. Check the roller pin and

roller bore for wear and replace if necessary.

Rollers

ROLLER PIN DISASSEMBLY

New roller retaining bolts have a dry locking agent

applied to the threads. Before attempting to remove

the roller pins, heat the threaded area lightly with a

propane torch. Wear heat resistant gloves during

this procedure. Use a high quality hexagonal

wrench in good condition to avoid screw damage. A

small amount of valve grinding compound can be

applied to the tip of the hex wrench to ensure a tight

fit. Always use new bolts if they are removed for

inspection. Apply Loctitet 680 retaining compound

sparingly to the tapered head

portion of the roller

retaining screws. Do not allow locking agent to

contact the inside of the rollers. Do not lubricate the

rollerorrollerpin.

Roller

Dry Locking

Agent Applied

To New Screws

Apply Loctitet

680 To Tapered

Portion Of Screw

Heat Area

Lightly

Roller

Retaining Screw

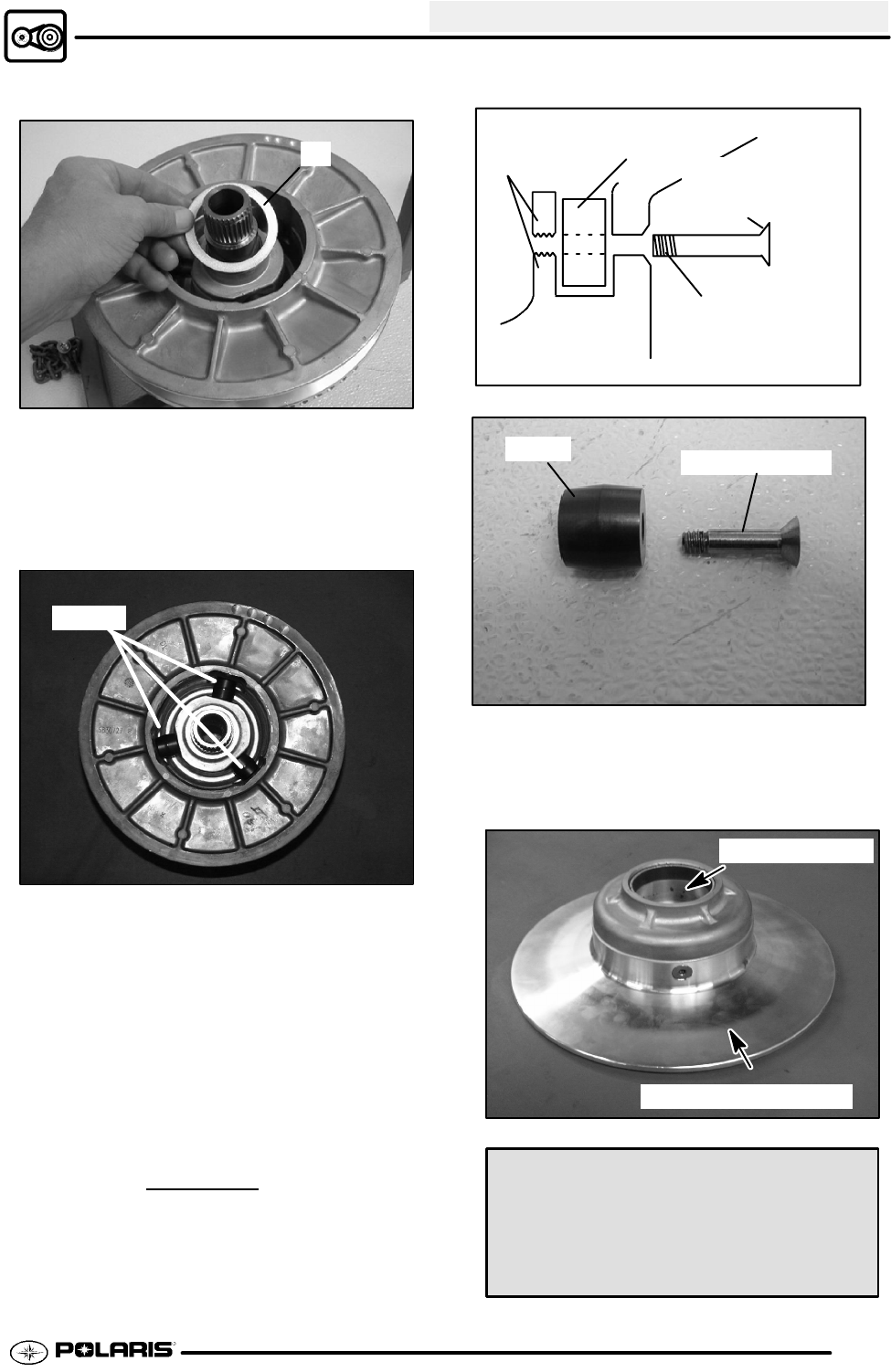

6. Inspect moveable sheave bushing for wear.

Inspect BOTH sheaves for signs of wear,

grooving or cracking. Clean surfaces with a 3Mt

pad if needed

Inspect Sheave Surface

Inspect Bearings

Moveable Sheave Bushing Inspection:

Replace the bushing if more brass than

Teflont is visible on the surface of the

bushing. See “EBS DRIVEN BUSHING

SERVICE” later in this chapter.