ELECTRICAL

10.38

STARTER SYSTEM

TROUBLESHOOTING

Starter Motor Does Not Turn

GBattery discharged. Low specific

gravity

GLoose or faulty battery cables or

corroded connections (see Voltage

Drop Tests)

GRelated wiring loose, disconnected, or

corroded

GPoor ground connections at battery

cable, starter motor or starter

solenoid (see Voltage Drop Tests)

GFaulty key switch

GFaulty kill switch

GFaulty starter solenoid or starter motor.

GEngine problem - seized or binding(Can

engine be rotated easily with recoil

starter?)

Starter Motor Turns Over Slowly

GBattery discharged - low specific

gravity

GExcessive circuit resistance - poor

connections (see Voltage Drop Test

below)

GEngine problem - seized or binding

(Can engine be rotated easily?)

GFaulty or worn brushes in starter

motor

GAutomatic compression release

inoperative

Starter Motor Turns - Engine Does Not Rotate

GFaulty starter drive

GFaulty starter drive gears or starter

motor gear

GFaulty flywheel gear or loose flywheel

VOLTAGE DROP TEST

The Voltage Drop Test is used to test for bad

connections. When performing the test, you are

testing the amount of voltage drop through the

connection. A poor or corroded connection will

appear as a high voltage reading. Voltage shown on

the meter when testing connections should not

exceed .1 VDC per connection or component

.

To perform the test, place the meter on DC volts and

place the meter leads across the connection to be

tested. Refer to the chart on 10.27 to perform voltage

drop tests on the starter system.

Voltage should not exceed

.1 DC volts per connection

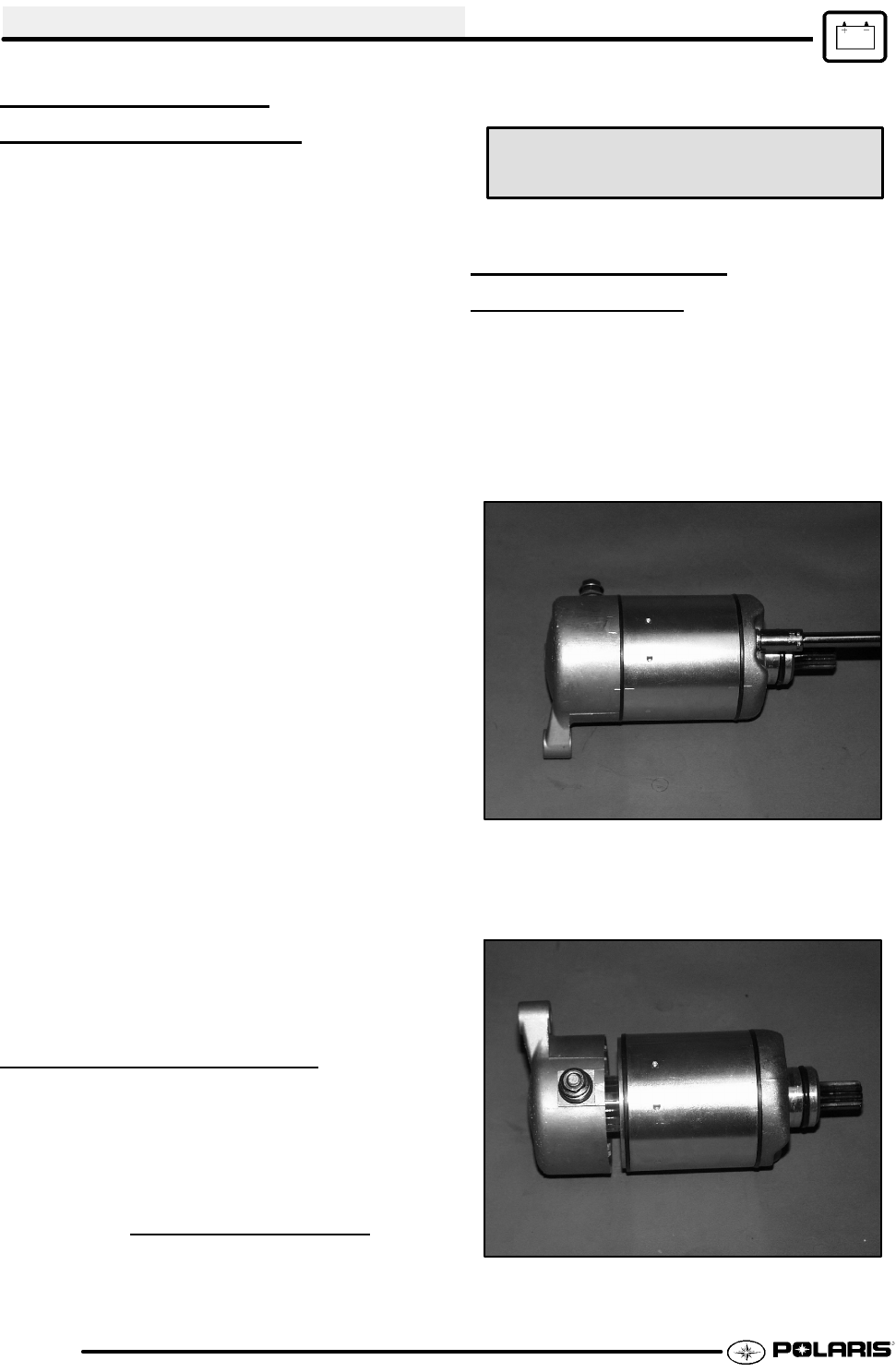

STARTER MOTOR

DISASSEMBL

Y

*NOTE: Use only electrical contact cleaner to clean

starter motor parts. Some solvents may leave a

residue or damage internal parts and insulation.

1. Note the alignment marks on both ends of the

starter motor casing. These marks must align

during reassembly.

2. Remove the two bolts, washers, and sealing

O-Rings. Inspect O-Rings and replace if damaged.

3. Remove brush terminal end of housing while

holding other two sections together.