ENGINE

3.21

CYLINDER HEAD

INSPECTION

(A)

1. Thoroughly clean cylinder head (A) surface to

remove all traces of gasket material and carbon.

CAUTION: Use care not to damage sealing

surface.

CYLINDER HEAD WARPAGE

Cylinder Head Warpage Limit:

.002″ (.05 mm)

1. Lay a straight edge across the surface of the

cylinder head at several different points and

measure warpage by inserting a feeler gauge

between the straight edge and the cylinder head

surface. If warpage exceeds the service limit,

replace the cylinder head.

CYLINDER HEAD

DISASSEMBL

Y

WARNING: Wear eye protection or a face shield

during cylinder head disassembly and reassembly.

NOTE: Keep all parts in order with respect to their

location in the cylinder head.

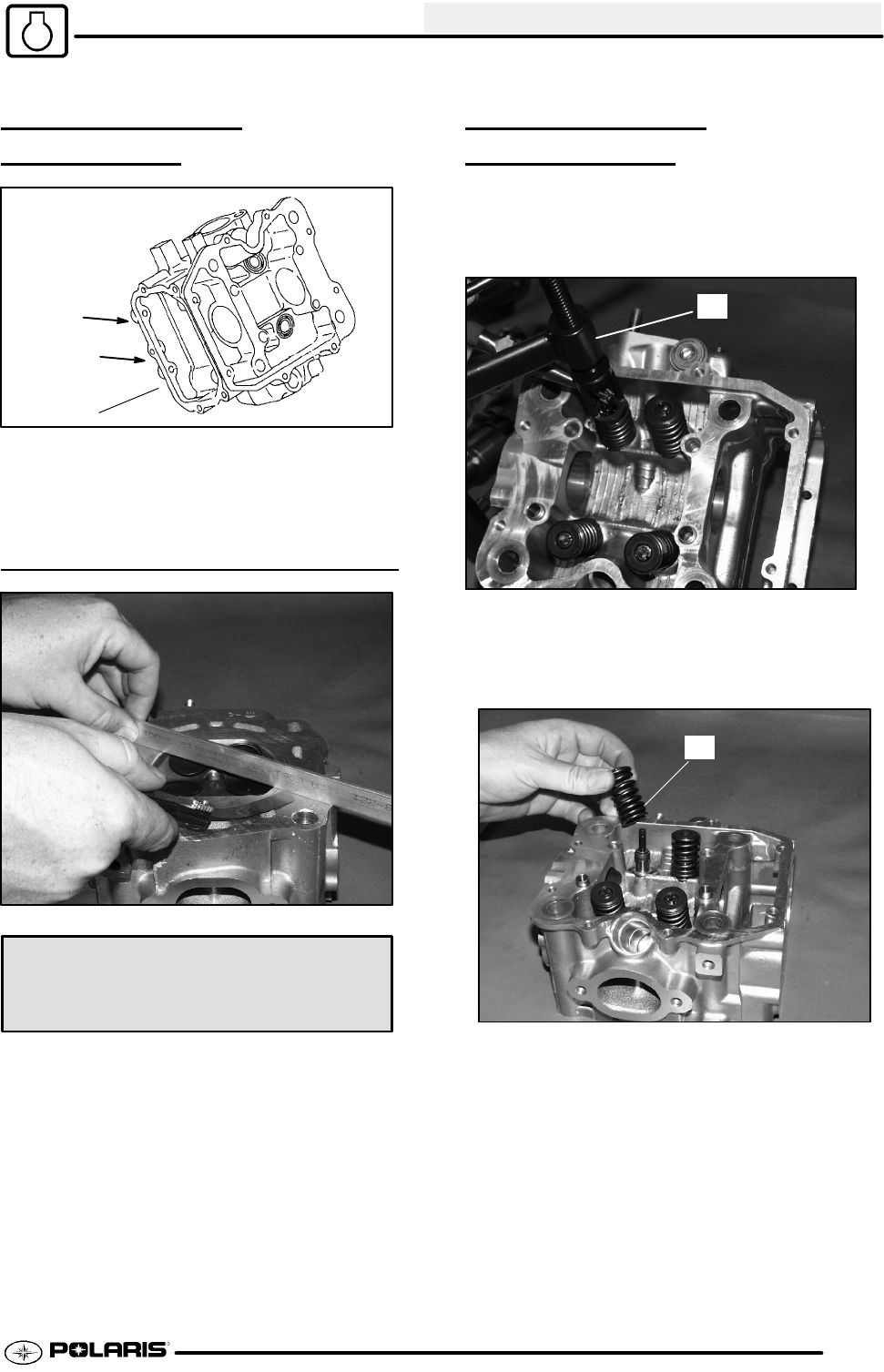

A

1. Using a valve spring compressor (A), compress

the valve spring and remove the split keeper.

NOTE: To prevent loss of tension, do not

compress the valve spring more than necessary.

A

2. Remove spring retainer and spring.

NOTE: The valve springs should be positioned with

the tightly wound coils against the cylinder head on

progressively wound springs (A).

3. Push valve out, keeping it in order for reassembly

in the same guide.

4. Measure free length of spring with a Vernier

caliper. Check spring for squareness. Compare