MAINTENANCE

2.32

HOSE/FITTING INSPECTION

Check brake system hoses and fittings for cracks,

deterioration, abrasion, and leaks. Tighten any loose

fittings and replace any worn or damaged parts.

AUXILIARY BRAKE TESTING

The auxiliary brake should be checked for proper

function.

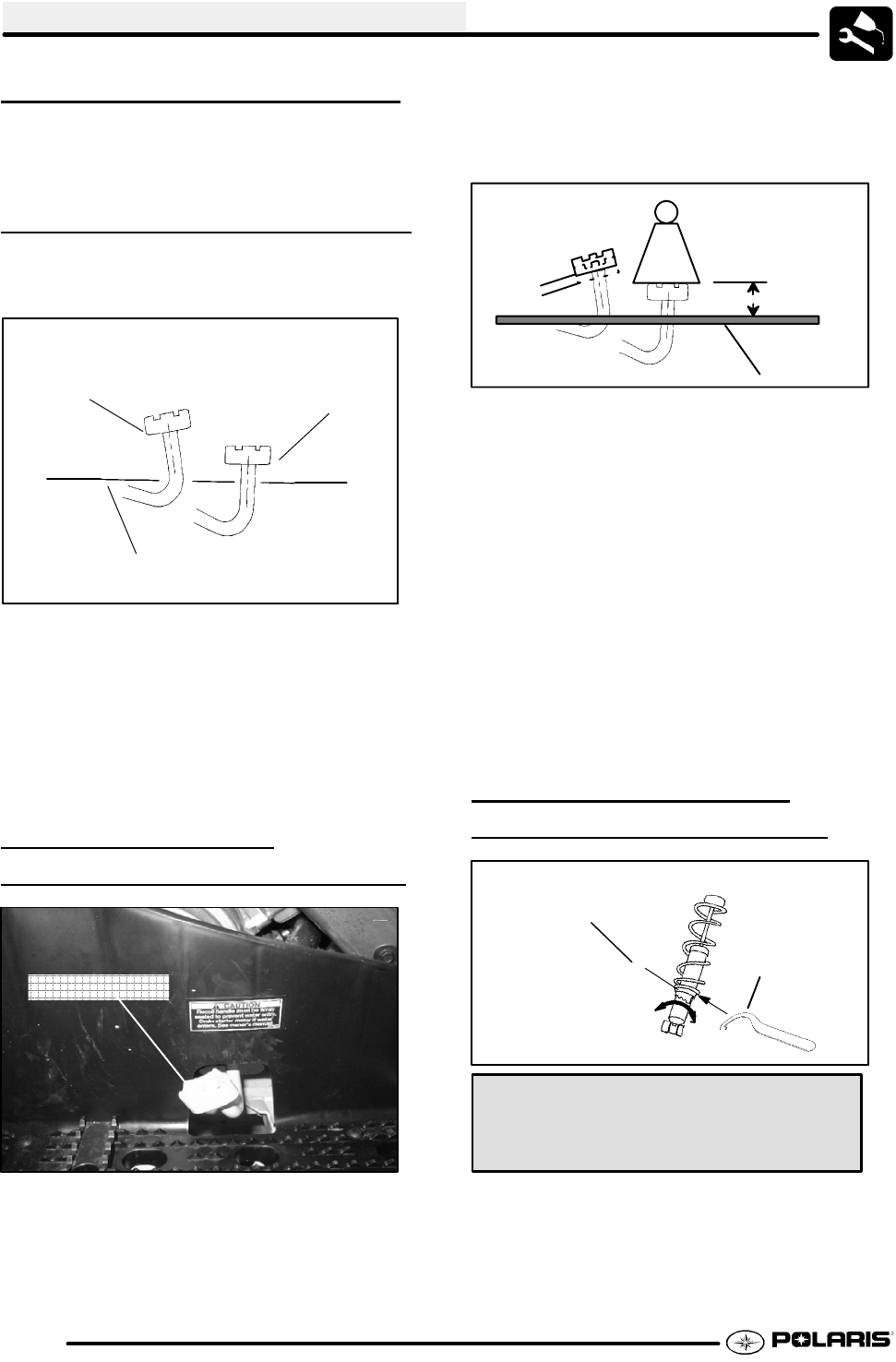

Auxiliary Foot Brake Pedal

Floor

Board Surface

Full Height

Full

Engagement

1. Support the rear wheels off the ground.

2. While turning the rear wheels by hand, apply the

auxiliary foot brake. This brake should not stop

the wheels from turning until the lever is half way

between its rest position and bottoming on the

footrest.

AUXILIARY BRAKE

ADJUSTMENT

(HYDRAULIC)

Auxiliary Brake

Use the following procedure to inspect the hydraulic

auxiliary (foot) brake system and adjust or bleed if

necessary:

First, check foot brake effectiveness by applying 50 lb.

(approx.) downward force onthe pedal. The top of the

pedal should be at least 1 inch, (25.4mm) above the

surface of the footrest.

50 lbs

1″ or greater

1/8, to 1/4,

Free Play

Floorboard

If less than one inch, two things must be examined:

Free Play:

Free play of the brake pedal should be 1/8 - 1/4

inch (3.2 - 6.35 mm).

If free play is excessive, inspect pedal, linkage, and

master cylinder for wear or damage and replace any

parts as needed.

Bleeding:

If free play is correct and brake pedal travel is still

excessive, air may be trapped somewhere in the

system. Bleed the hydraulic auxiliary brake system in

a conventional manner, following the procedure

outlined in Brake Chapter 9.

SUSPENSION SPRING

PRELOAD

ADJUSTMENT

Center Spring

Adjustment Ring

2

1

Shock Spanner Wrench

(PN 2871095)

Operator weight and vehicle loading affect

suspensionspringpreloadrequirements.Adjustas

necessary, using the spannerwrench(2)supplied

in your ATV tool kit to turn the adjustment cam (1).