6. TROUBLESHOOTING

6-12

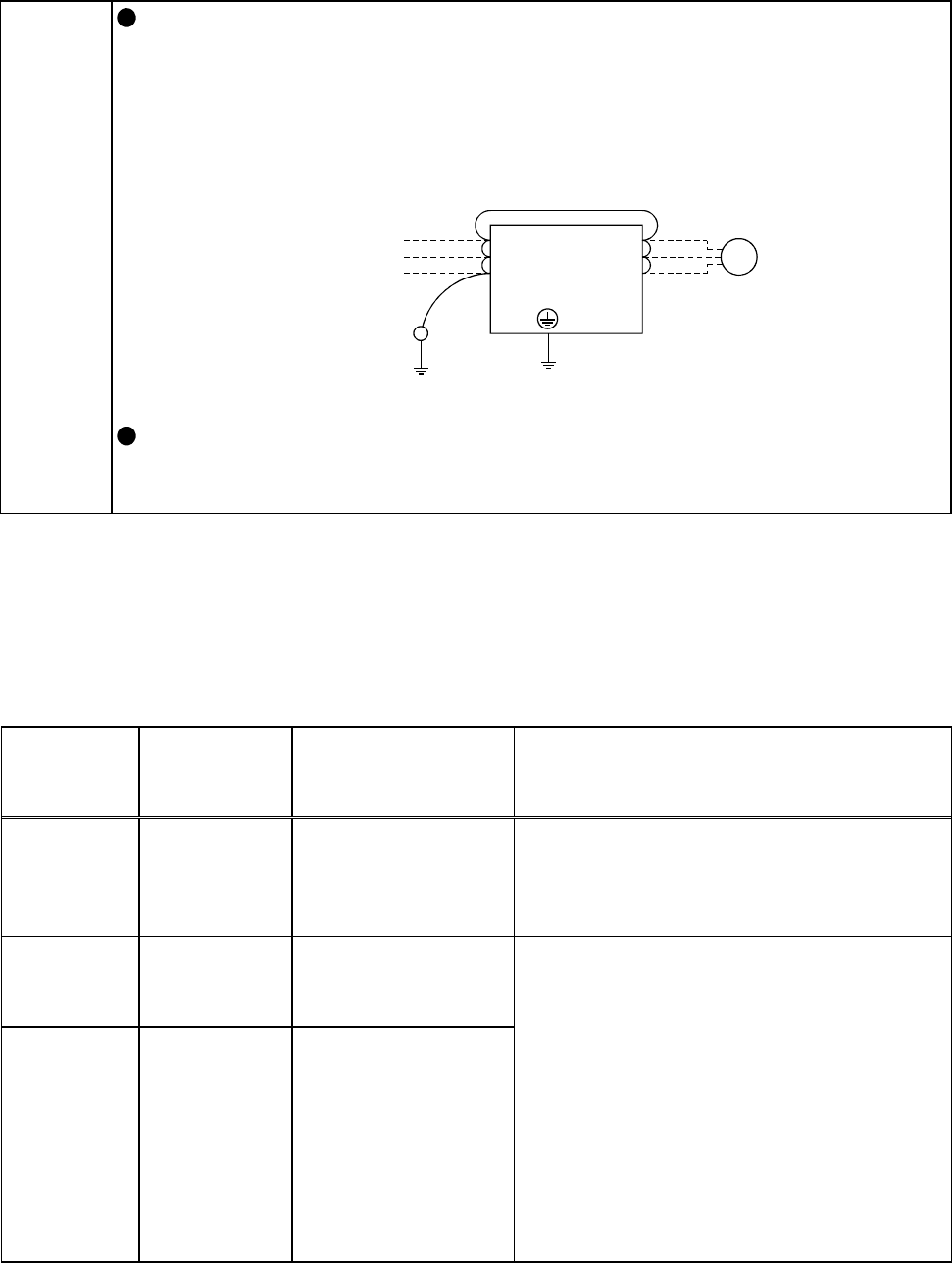

NOTICE

Insulation resistance test using megger

Where possible, do not conduct an insulation resistance test using a megger since

an insulation test has been done before shipment from the factory. When it is

inevitable to make an insulation resistance test using a megger, disconnect all

cables from the control circuit to prevent a test voltage from leaking into the control

circuit. The drive unit will fail if the test voltage is applied to the control circuit.

R

S

T

U

V

W

M

Motor

Power supply

500VDC

megger

Drive unit

Earth terminal

Pressure test

Do not conduct a pressure test. A pressure test can deteriorate the semiconductor

parts in the drive unit.

6.4.2 Wear parts

The replacement lives of the parts are as indicated below. Since the lives vary with the operating

environment and/or usage, you must replace the parts if you have found any fault during periodic

inspection or the like.

Part Name

Standard

Replacement

Intervals

Method Remarks

Cooling fan 2 to 3 years Change (as required)

The bearing life of the cooling fan is 10,000

to 35,000 hours. For continuous operation,

therefore, normally replace the fan every 2

to 3 years as a guideline.

Main circuit

smoothing

capacitor

10 years Change (as required)

On-board

smoothing

capacitor

10 years Change (as required)

The life greatly depends on the ambient

temperature and operation specifications of

the drive unit. When continuous operation is

performed in normal air-conditioned

environment, the life is approximately 10

years. The life halves for each 10

°

C rise in

ambient temperature.

The capacitor deteriorates rapidly after the

given period has elapsed, causing the motor

to run unstably or activating the overcurrent

protective function.