6. TROUBLESHOOTING

6-7

6

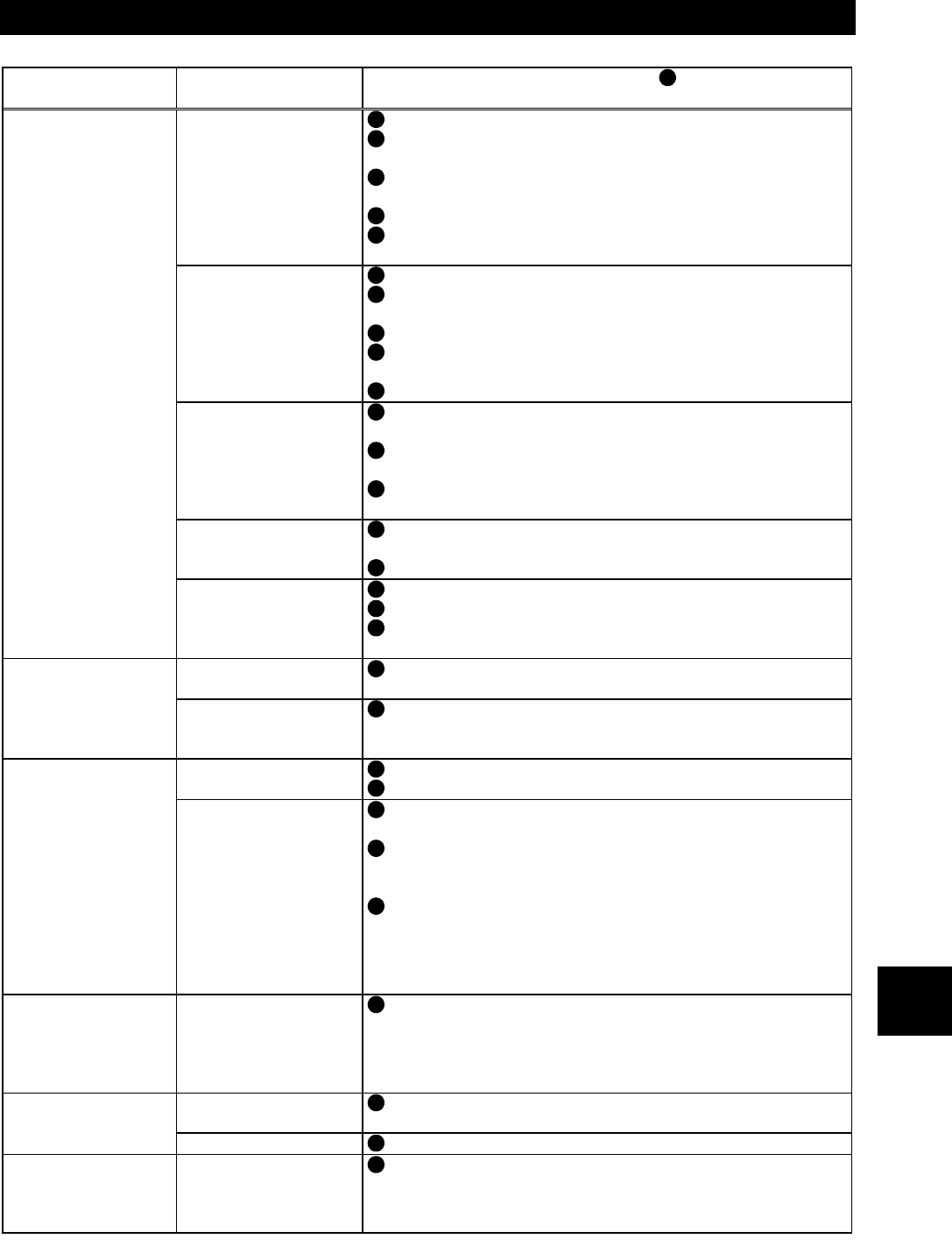

6.2 Motor operation out of ordinary

If any of the following faults has occurred in the motor, find out its cause and take adequate measures.

Event Check Point

Estimated Cause (

)

and

Corrective Action (

•

)

Check the main

circuit.

A normal power supply voltage is not applied.

The jumper across terminals R1-S1 has been

disconnected.

The jumper across terminals P/+-P1 has been

disconnected.

The motor is not wired properly.

The switch connected between the motor and drive

unit is open.

Check the control

signals.

The start signal has not been initiated.

Both the forward and reverse rotation signals are

input.

The speed setting signal is not input.

The AU signal is not ON for the 4 to 20mA speed

setting signal.

The MRS signal remains ON.

Check the

parameter settings.

The reverse rotation prevention, Pr. 78 [Section

8.5.1], value has been set.

The operation mode, Pr. 79 [Section 8.2], setting is

incorrect.

0 was set as the maximum speed, Pr. 1 [Section

8.5.1], value.

Check the load.

The load is too heavy.

(The alarm message OL appears.)

The motor shaft is locked.

Motor remains

stopped.

Others

The alarm lamp is lit.

The POWER lamp is off.

The capacities of the drive unit and motor do not

match.

Check the main

circuit.

The wiring of the motor connection terminals U, V, W

does not match the motor phase sequence.

Motor rotates in

opposite direction.

Check the control

signals.

The wiring of the forward rotation signal (terminal

STF) and that of the reverse rotation signal (terminal

STR) was exchanged.

Check the control

signals.

The speed setting signal differs from the setting.

The speed setting signal is compounded with noise.

Speed differs from

the setting.

Check the

parameter settings.

The speed signal bias/gain, Pr. 902 to 905 [Section

8.3.1], values have been set.

The maximum speed, Pr. 1 [Section 8.5.1], value or

minimum speed, Pr. 2 [Section 8.5.1], value has

been set.

The stall prevention function, Pr. 22 [Section 8.5.6]

was activated.

•

Increase the acceleration or deceleration time

setting.

•

Reduce the load.

Acceleration/

deceleration is not

smooth.

Check the

parameter settings.

The stall prevention function, Pr. 22 [Section 8.5.6]

was activated.

•

Increase the acceleration or deceleration time

setting.

•

Reduce the load.

Check the control

signals.

The speed setting signal varies.

Speed varies.

Check the load.

The load varies.

At start, motor

shaft runs in

opposite direction

instantaneously.

Check the

parameter settings.

The acceleration time setting is more than that for the

maximum permissible starting torque.

•

Increase the acceleration time setting.