ENGINE

3.37

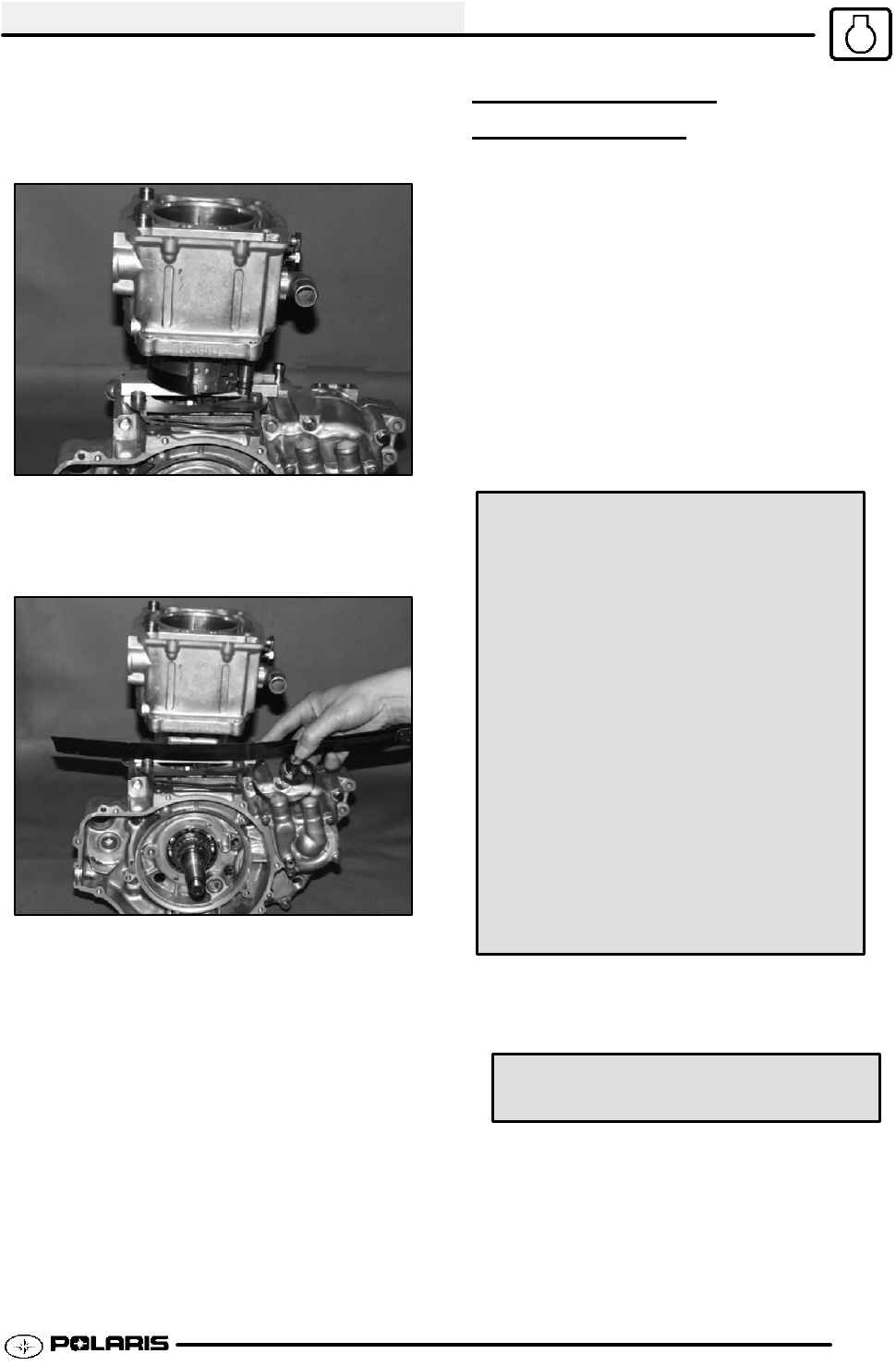

3. Apply clean engine oil to the ring compressor and

install the compressor according to the

manufacturers instructions. CAUTION: Verify all

ring end gaps are correctly located.

4. Apply clean engine oil liberally to the cylinder bore

and tapered area of the sleeve. Install the

cylinder with a slight rocking motion until the rings

are captive in the sleeve.

5. Remove the ring compressor and support block.

6. Push the cylinder downward until fully seated on

thebasegasket.

7. Rotate the engine and position the piston at BDC.

NOTE: If cam chain is installed, hold it up while

rotating the engine to avoid damage to the chain, drive

sprocket teeth, or tensioner blade.

CYLINDER HEAD

INSTALLA

TION

Clean the gasket surfaces on the cylinder head and

cylinder. Remove all traces of old gasket material.

Refer to disassembly photos.

1. Install the cam chain tensioner guides. Be sure

bottom end of guide is located properly in

crankcase.

2. Install the two dowels and a new cylinder head

gasket.

3. Place the cylinder head on the cylinder. Apply a

film of engine oil to the cylinder head bolt threads

and washers, and hand tighten the bolts.

The following procedure must be used to torque the

cylinder head properly:

**TORQUE ALL BOLTS EVENLY

IN A CRISS--CROSS PATTERN

1 -- Torque bolts to 22 ft. lbs. (30 Nm)

2 -- Torque bolts to 51 ft. lbs. (70 Nm)

Leave at this torque for 1 minute to allow

gaskets to seat for proper sealing.

3 -- Loosen bolts evenly 360q (1 turn)

4 -- Torque bolts to 29 ft. lbs. (35 Nm)

5 -- From this point, tighten bolts

evenly 90q (1/4 turn)

6 -- Finally, tighten another 90q (1/4

turn)

7 -- Install two 6mm bolts and torque

to 6 ft. lbs. (8 Nm)

4. Install the two 6 mm bolts and torque to

specification.

Cylinder 6mm Bolt Torque:

6 ft. lbs. (8 Nm)

Enfocus Software - Customer Support