MAINTENANCE

2.26

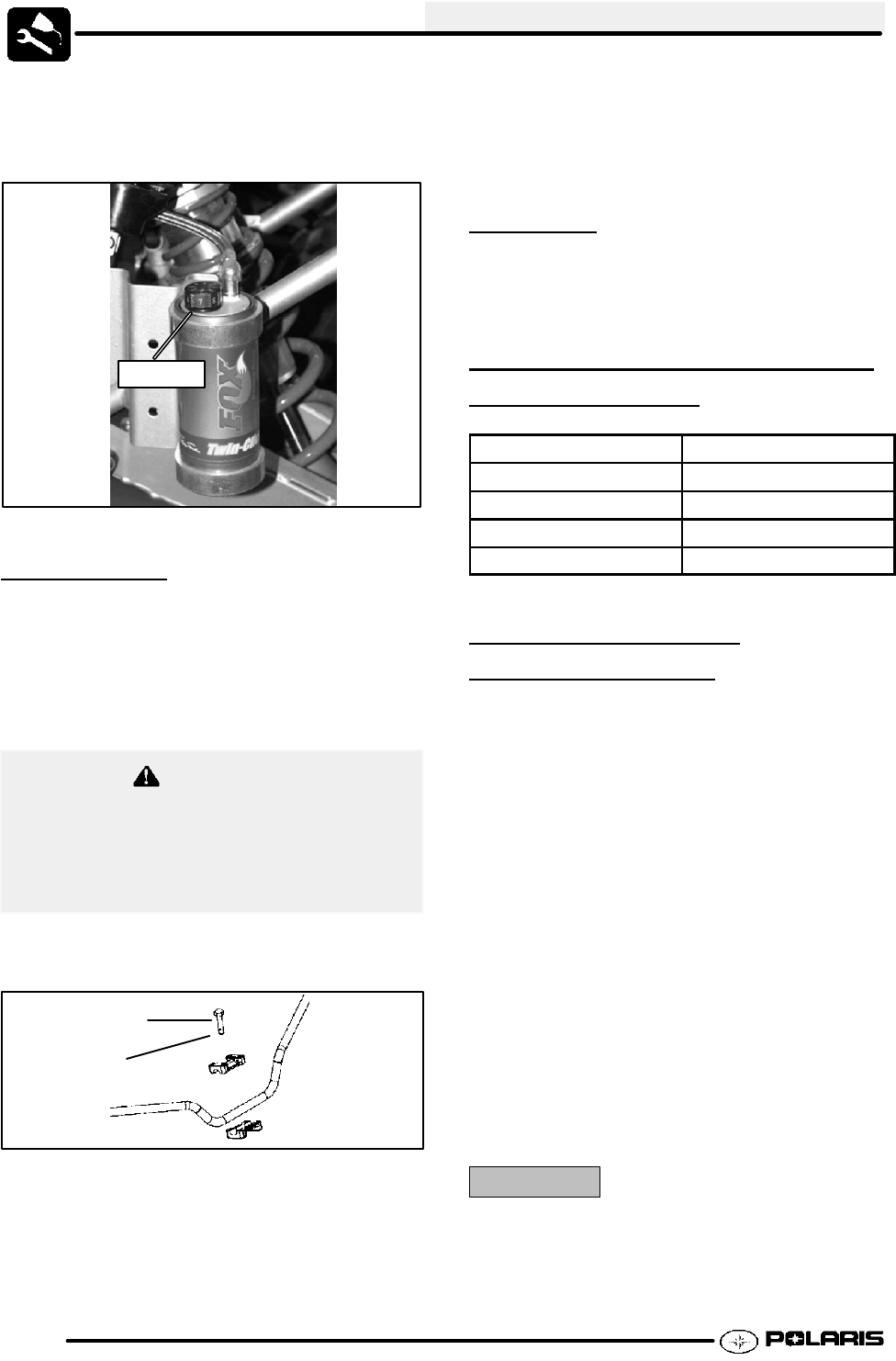

It has eight possible positions ranging from position 1

(softest) to 8 (firmest). The compression damping is

factory set at position 4. To adjust, turn the clicker

drum to the desired setting.

Adjust

CONTROLS

Check controls for proper operation, positioning

and adjustment.

Handlebars

If desired, the handlebars can be adjusted for rider

preference.

Improper adjustment of the handlebars or incorrect

torquing of the adjuster block bolts can cause

limited steering or loosening of the handlebars,

which could result in loss of control and serious

injury or death.

WARNING

1. Remove the instrument panel and locate the

handlebar bolts (1).

1

10--12 ft.lbs.

(14--17 Nm)

2. Loosen the four bolts and adjust the handlebar to

the desired height. Be sure the handlebars do not

contact the gas tank or any other part of the

machine when turned fully to the left or right.

3. Torque the front two bolts to 10-12 ft. lbs. (14-17

Nm), then torque the rear two bolts. A gap of up to

1/8” will remain at the rear bolts.

WHEELS

Inspect all wheels for runout or damage. Check wheel

nuts and ensure they are tight. Do not over tighten the

wheel nuts.

WHEEL, HUB, AND SPINDLE

TORQUE T

ABLE

Item Specification

Front Wheel Nuts 20 Ft. Lbs. (41 Nm)

Rear Wheel Nuts 20 Ft. Lbs. (41Nm)

Front Spindle Nut 40 Ft. lbs. (55 Nm)

Rear Hub Retaining Nut 80 Ft. Lbs. (108 Nm)

WHEEL REMOVAL:

FRONT OR REAR

Wheel Removal

1. Stop the engine, place the transmission in gear

and lock the parking brake.

2. Loosen the wheel nuts slightly.

3. Elevate the side of the vehicle by placing a

suitable stand under the footrest frame.

4. Remove the wheel nuts and remove the wheel.

Wheel Installation

1. With the transmission in gear and the parking

brake locked, place the wheel in the correct

position on the wheel hub. Be sure the valve stem

is toward the outside and rotation arrows on the

tire point toward forward rotation.

2. Attach the wheel nuts and finger tighten them.

3. Lower the vehicle to the ground.

4. Securely tighten the wheel nuts to the proper

torque listed in the table.

CAUTION:

Enfocus Software - Customer Support