BRAKES

6.12

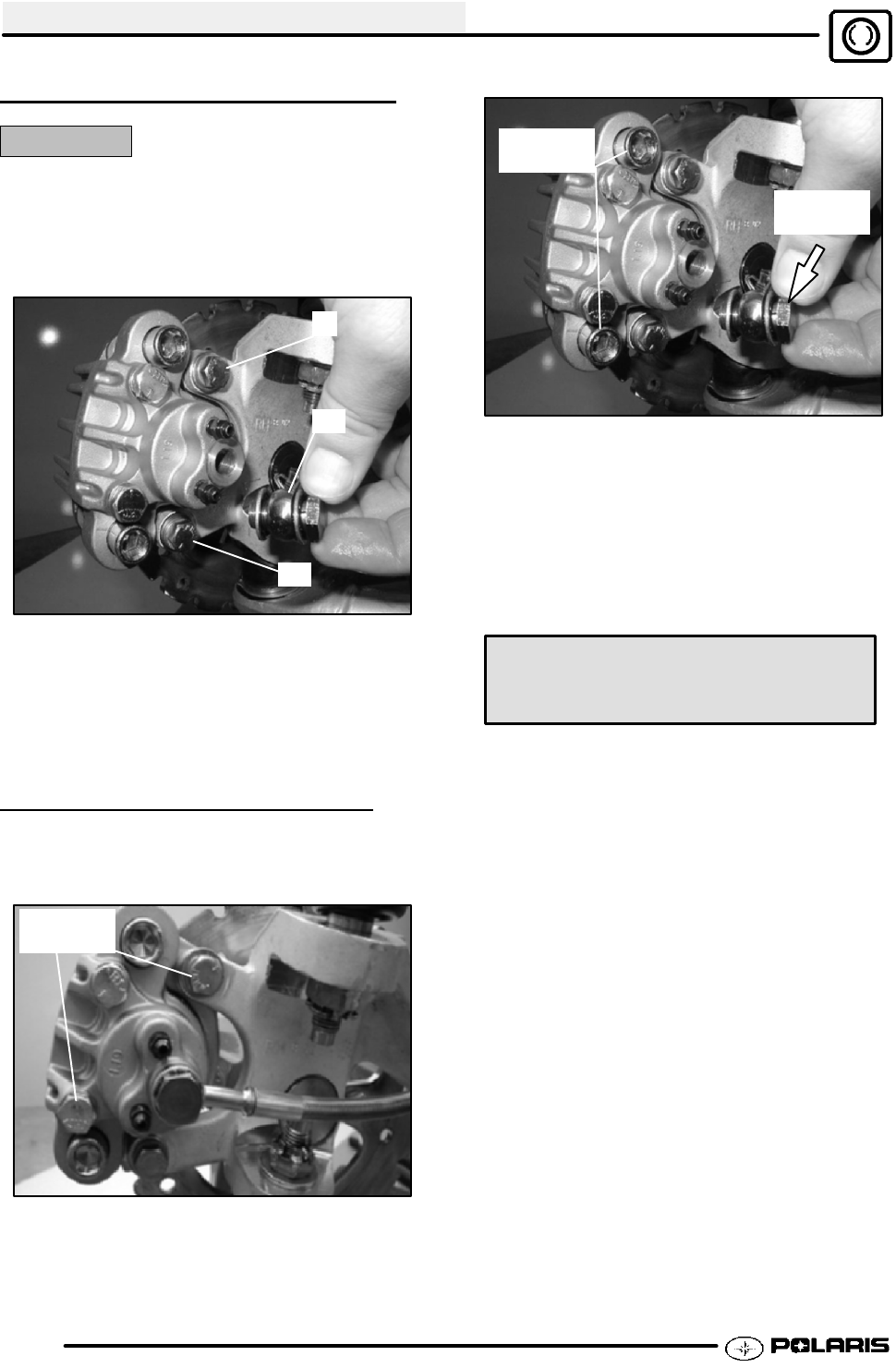

FRONT CALIPER REMOVAL

CAUTION:

Use care when supporting vehicle so that it does not

tip or fall. Severe injury may occur if machine tips or

falls.

1. Remove brake pads. See Page 6.8.--6.9.

A

B

B

2. Using a line wrench, loosen and remove brake

line (A) to caliper. Place a container under caliper

to catch fluid draining from brake line. Drain the

fluid into the container.

3. Remove the two brake caliper mounting bolts (B)

and remove the brake caliper.

FRONT CALIPER INSTALL

1. Install caliper on hub strut, and torque mounting

bolts to 18 ft.lbs. (25 Nm).

18 ft.lbs.

(25 Nm)

2. Install brake line and tighten securely with a line

wrench.

33 ft.lbs.

(45 Nm)

15 ft.lbs.

(21 Nm)

3. Torque the caliper slide bolts to 33 ft.lbs. (45

Nm). Torque the banjo line bolt to 15 ft.lbs. (21

Nm).

4. Follow brake bleeding procedure outlined on

Pages 6.5-6.6.

5. Install wheels and torque wheel nuts to

specification.

Front Wheel Nut Torque

20 ft. lbs. (28 Nm).

NOTE: BRAKE BURNISHING: It is recommended

that a burnishing procedure be performed after

installation of new brake pads to extend service

life and reduce noise. Start machine and slowly

increase speed to 30 mph. Gradually apply brakes

to stop machine. Repeat this procedure 10 times,

allowing brakes to cool sufficiently after each

run.

Enfocus Software - Customer Support

Enfocus Software - Customer Support