MAINTENANCE

2.12

5. Reverse the procedures to install the fuel valve.

6. Start engine and inspect for leaks.

CARBURETOR DRAINING

The carburetor float bowl should be drained

periodically to remove moisture or sediment from the

bowl, or before extended periods of storage.

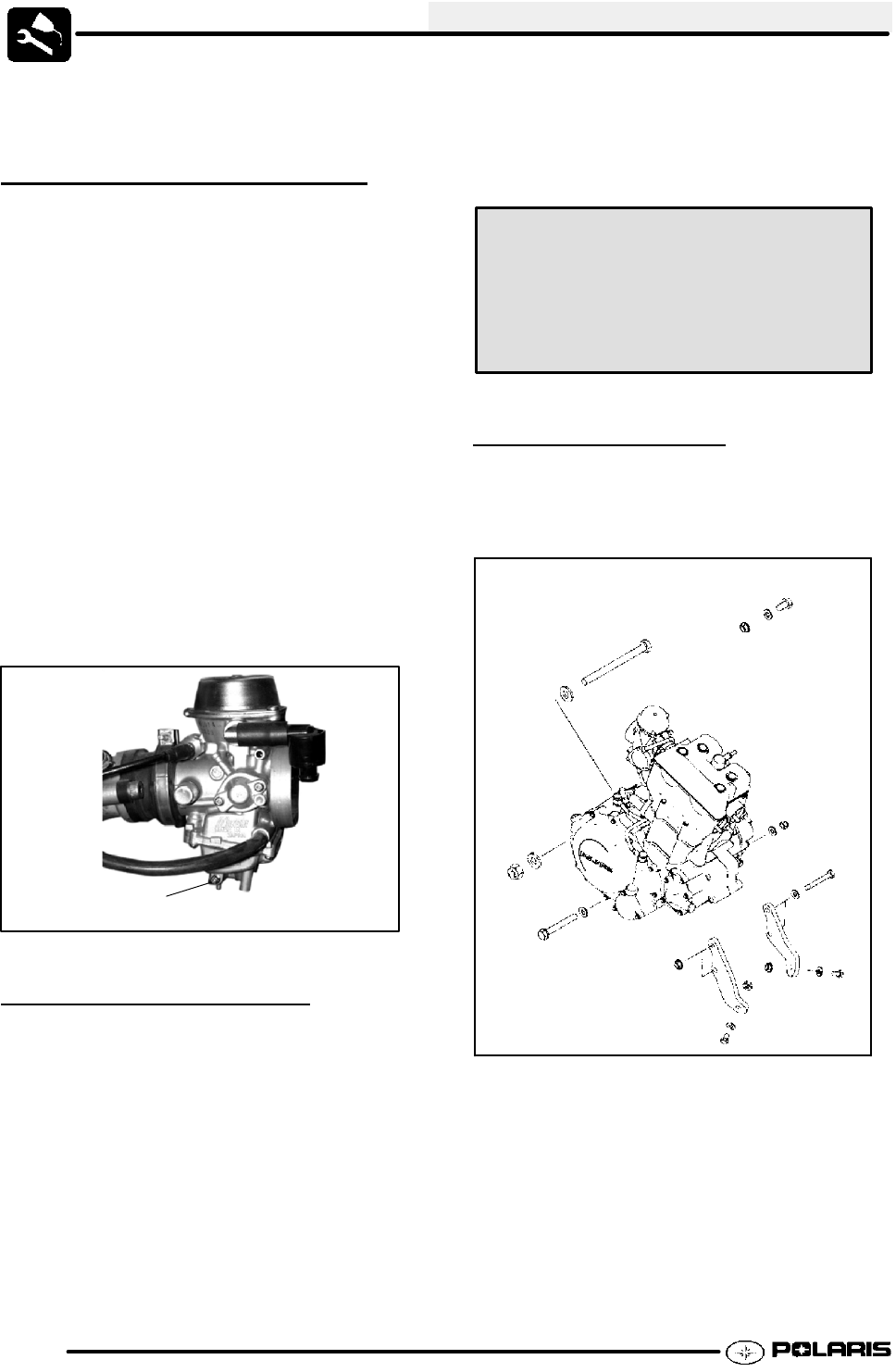

NOTE: The bowl drain screw is located on the bottom

left side of the float bowl.

1. Turn fuel valve to the off position.

2. Place a clean container beneath the bowl drain

spigot or bowl drain hose.

3. Turn drain screw out two turns and allow fuel in

the float bowl and fuel line to drain completely.

4. Inspect the drained fuel for water or sediment.

5. Tighten drain screw.

6. Turn fuel valve to “ON”.

7. Start machine and check for leaks.

NOTE: All tubes attached to the carburetor must be

check for pinching or blockage, as this will effect

engine performance.

Drain Screw

Ill. 1

COMPRESSION TEST

NOTE: This engine has built--in decompression

components. Compression readings will vary in

proportion to cranking speed during the test. Average

compression (measured) is about 85--90 psi @ 400

RPM during a compression test.

A smooth idle generally indicates good compression.

Low engine compression is rarely a factor in running

condition problems above idle speed. Abnormally

high compression can be caused by carbon deposits

in the combustion chamber or worn, damaged

exhaust cam lobes. Inspect camshaft and

combustion chamber if compression is abnormally

high.

A cylinder leakdown test is the best indication of

engine condition. Follow manufacturer’s instructions

to perform a cylinder leakage test. (Never use high

pressure leakage testers, as crankshaft seals may

dislodge and leak).

Cylinder Leakdown

Service Limit 10 %

(Inspect for cause if leakage exceeds 10%)

Cylinder Compression

w/ decompression

Standard: 85--90 PSI @ 400 RPM

ENGINE MOUNTS

Inspect engine mounts and frame for cracks or

damage. (Ill.3)

Check engine fasteners and ensure they are tight.

Ill. 3

Enfocus Software - Customer Support