MAINTENANCE

2.24

SPROCKET INSPECTION

Inspect the sprocket for worn, broken or bent teeth.

Chain Tension

Limit:

1/4s (6mm)

Inspect chain for excessive

wear, missing o--rings, etc.

To check for wear, pull upward on the chain. Replace

sprocket if chain movement exceeds 1/4s (.6 cm).

DRIVE CHAIN INSPECTION

The chain must be replaced when it reaches 3%

elongation.

1. Stretch the chain tightly in a straight line.

2. Measure the length of twenty pitches (pins) from

pin center to pin center, and compare to the

specification. Replace the chain if the length

exceeds the wear limit.

Drive Chain Wear Limit, 20 Pitch Length:

Std: 12.5s (32 cm)

Wear Limit: 12.875s (32.7 cm)

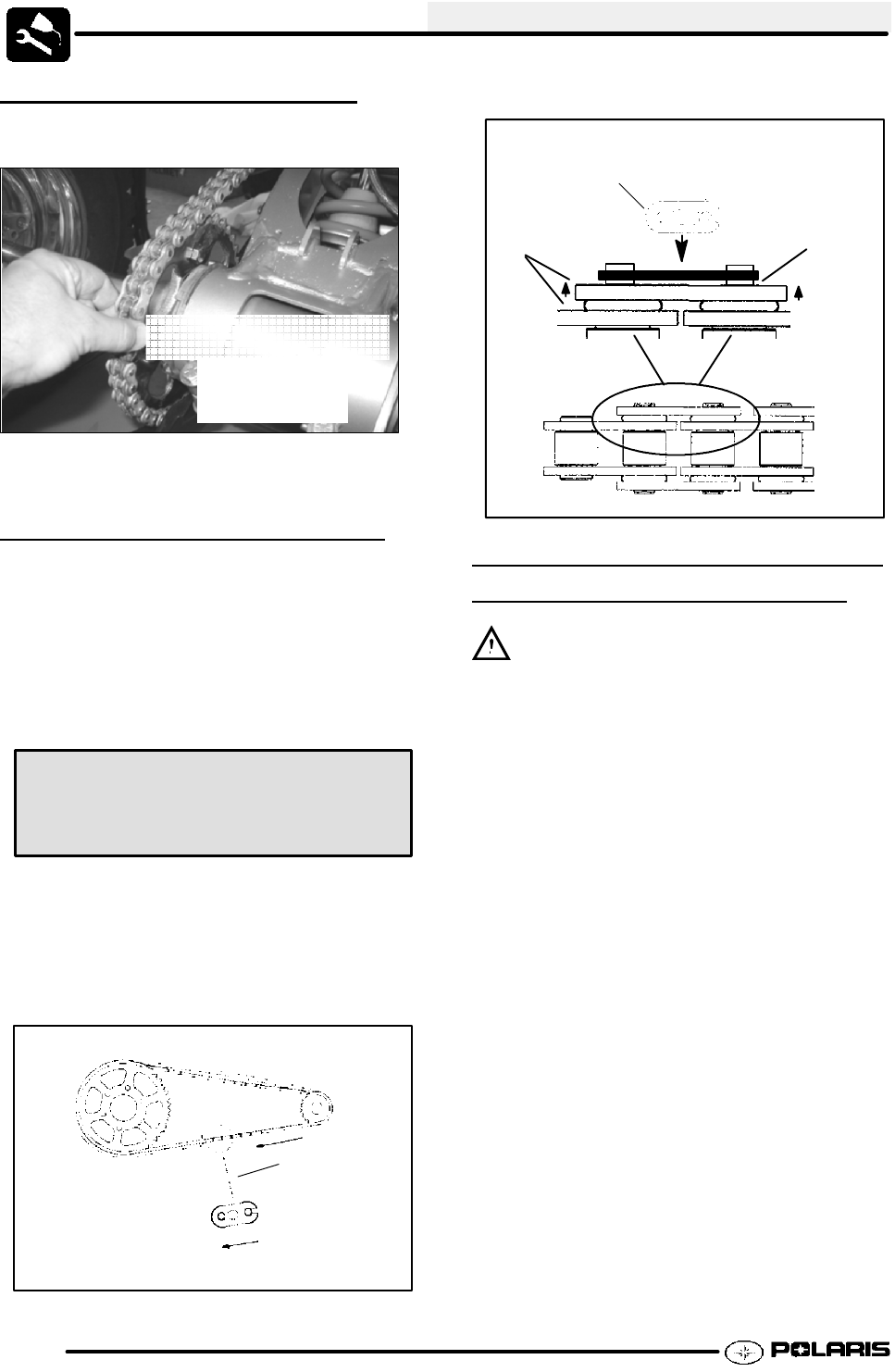

3. When replacing or reinstalling drive chain, install

the closed end of the splice link clip as shown, with

the closed end leading in forward operation.

There should be a .003--.005” (.076--.127 mm)

gap between the side plate of the chain and the

splice link clip. See Illustrations 1 and 2.

Proper

Splicelink Clip

Opening

Position

Rear Chain

Shown

.003--.005”

(.076--.127 mm)

Gap after installation

Ill. 1

If there is space

between outside

edge of the mas-

ter link and plate,

back the plate

out slightly.

Master Link

Do not

press plate

in too far.

Ill. 2

DRIVE CHAIN ADJUSTMENT,

CONCENTRIC

SWINGARM

CAUTION: Never adjust or operate the vehicle

with the rear drive chain too loose or too tight as

severe damage to the transmission and drive

components can result. Chain tension must be

inspected with the swing arm in the position shown in

the illustration so that the axle, swingarm pivot, and

drive spocket are aligned horizontally (B).

Break-In: It is extremely important to maintain proper

chain tension to ensure the best possible chain life.

There is a chain break-in period of approximately 100

miles or two (2) tanks of fuel. During this time chain

tension should be watched very closely and loads to

the chain should be kept light.

Checking Chain Tension:

Check the amount of chain slack by moving the

vehicle slightly forward to gain slack at the top side of

the rear chain.

1. Collapse the suspension with an adjustable

(buckle type) trailer tie down strap (A). Fasten the

strap around the axle and rear bumper tube.

2. Tighten the strap until a straight line (B) can be

drawn from the axle to the transmission output

shaft, intersecting the swing arm pivot. This

establishes the tightest chain position.

3. At this point (C) the chain should have 1/4” - 3/8“

(0.6 -0.9 cm) deflection. Use the procedure on

the following page if the chain needs adjustment.

Enfocus Software - Customer Support