ENGINE

3.14

4. To retract the plunger, rotate the special tool

clockwise while holding the tensioner stationary.

You may also hold the special tool stationary and

rotate the tensioner assembly counter--clockwise

if desired. I MPORTANT: Do not grind edges of

key flange into tensioner to prevent damage to the

tool or locking guides during plunger retraction.

5. Once retraction is complete, lock the tool into the

tensioner guides. This holds the spring and

plunger in place for reassembly. Use caution not

to disturb the tool during tensioner installation.

6. Reinstall the tensioner assembly, torquing the

bolts to specification (Pg 3.2). Remove the

special tool and replace the tensioner cap.

Tensioner Bolt Torque:

6.6-8.1 ft lbs (9-11 Nm)

CAMSHAFT REMOVAL AND INSPECTION

1. Remove the valve cover.

2. Remove the tensioner assembly.

3. Remove the 8 bolts securing the cam tower

assembly and remove the cover.

4. To free the cam assembly, lift one cam assembly

and slightly rotate it while removing the chain from

the cam gear. Repeat this procedure for the other

cam. NOTE: Do not allow cam chain to drop

into the engine if no other disassembly is

being performed.

5. Use a device to secure the cam chain, such as

mechanic’s wire or nylon line, to prevent it from

falling into the engine.

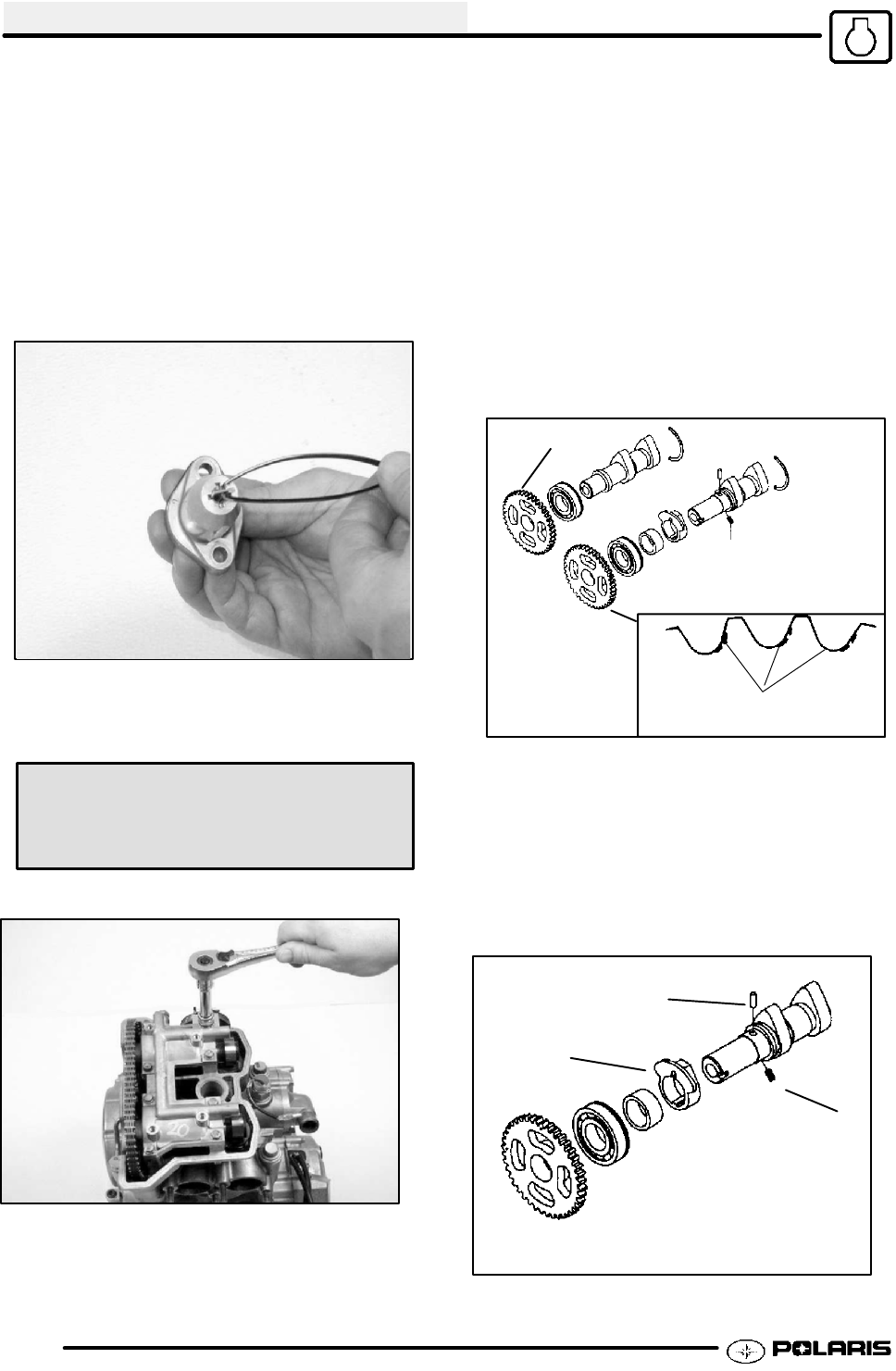

6. Inspect cam sprocket teeth for wear or damage.

If damage is found, replace the camshaft

assembly.

Inspect for Areas of Tooth

Wear or Damage

Sprocket Teeth

AUTOMATIC COMPRESSION RELEASE

INSPECTION

NOTE: The automatic compression release

mechanism cannot be serviced. The components

are not replaceable. Replace the camshaft as an

assembly if any part of the compression release is

worn or damaged.

A

B

C

Note: Cam and compression--release

are an assembly and not serviceable

Enfocus Software - Customer Support