FUEL SYSTEM/CARBURETION

4.11

fitting. Apply 5 PSI pressure to inlet fitting. The

needle and seat should hold pressure indefinitely.

If not, inspect needle and seat and seat O-ring.

Mity Vact (PN 2870975)

FUEL LEVEL

A fuel level test can be performed on some models if

the drain hose fitting is accessible. Be sure to

re-attach the bowl drain hose after performing the

test. A fuel level test allows you to observe the height

of the fuel in the float bowl without removing the

carburetor. The fuel level can be observed with the

engine either running or shut off, however, engine

must run briefly to allow fuel level to stabilize..

1. Attach a clear line to drain fitting. Be sure line fits

tightly on fitting. Position hose along side of

carburetor as shown.

1.5 mm

.060s

Bowl Mat-

ing

Surface

2. Open bowl drain screw by turning

counterclockwise approximately two turns. Start

and run engine for 3 to 5 seconds to allow fuel

level to stabilize in the line. If level is out of

specification, remove carburetor and inspect inlet

needle and seat, float height, passages, etc.

NOTE: If a line was removed to perform this

procedure, it must be replaced.

FUEL PUMP

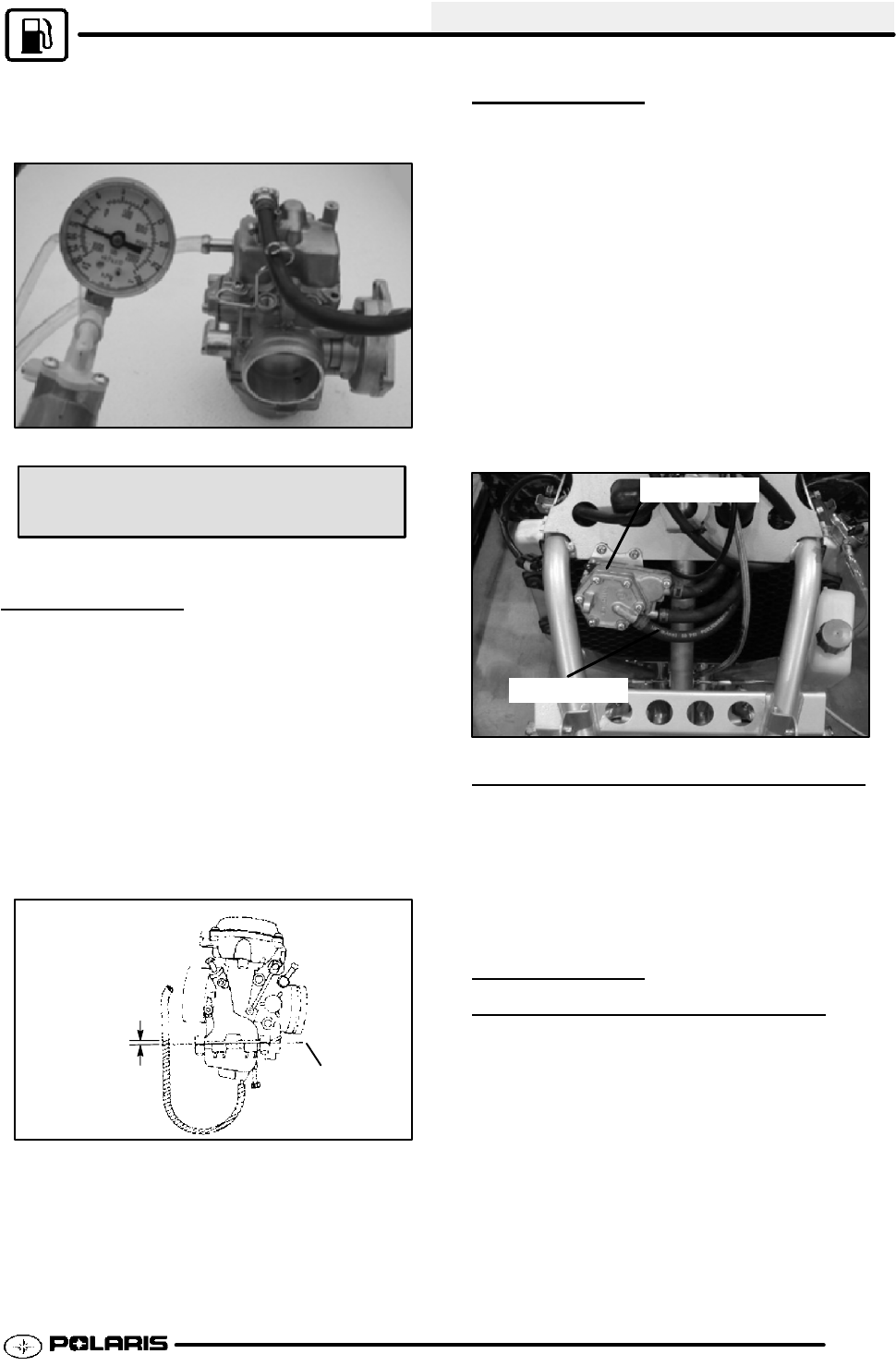

The Predator 500 is equipped with a pressure

regulated fuel pump (1-3 PSI). The pump is located

in the front fender cavity of the machine.

To test the fuel pump:

1. Turn fuel off.

2. Disconnect impulse line from pump.

3. Connect Mity-Vact (PN 2870975) to the impulse

line fitting on the pump.

4. Apply 5 inches (Hg) vacuum to the pump fitting.

The diaphragm should hold vacuum indefinitely.

If fuel is present in the impulse line or vacuum

chamber of the pump, the diaphragm is ruptured. The

pump diaphragms must be replaced.

Fuel Pump

Impulse line

FUEL PUMP DISASSEMBLY

1. Remove the screws from the pump diaphragm

cover. Note the location of the two longer screws.

2. Remove the diaphragm cover gasket,

diaphragm, and valve body gasket.

3. Remove the outlet check valve cover, diaphragm,

and gasket.

FUEL PUMP

INSPECTION/ASSEMBL

Y

1. Inspect inlet and outlet check valves for cracks,

warpage or damage. Inspect the diaphragms for

cracks, holes or swelling.

2. To clean the valves or pump body, remove the set

screw and washer. Remove the valve and wash

with soap and water. Carburetor cleaner may be

used to clean the pump body when the check

valves are removed. CAUTION: Some

carburetor cleaners are very caustic and should

not be used to clean the non-metal parts of the

fuel pump.

3. Check the sealing surfaces of the pump body and

covers. Carefully remove all traces of old gasket

Enfocus Software - Customer Support