ENGINE

3.9

CRANKSHAFT

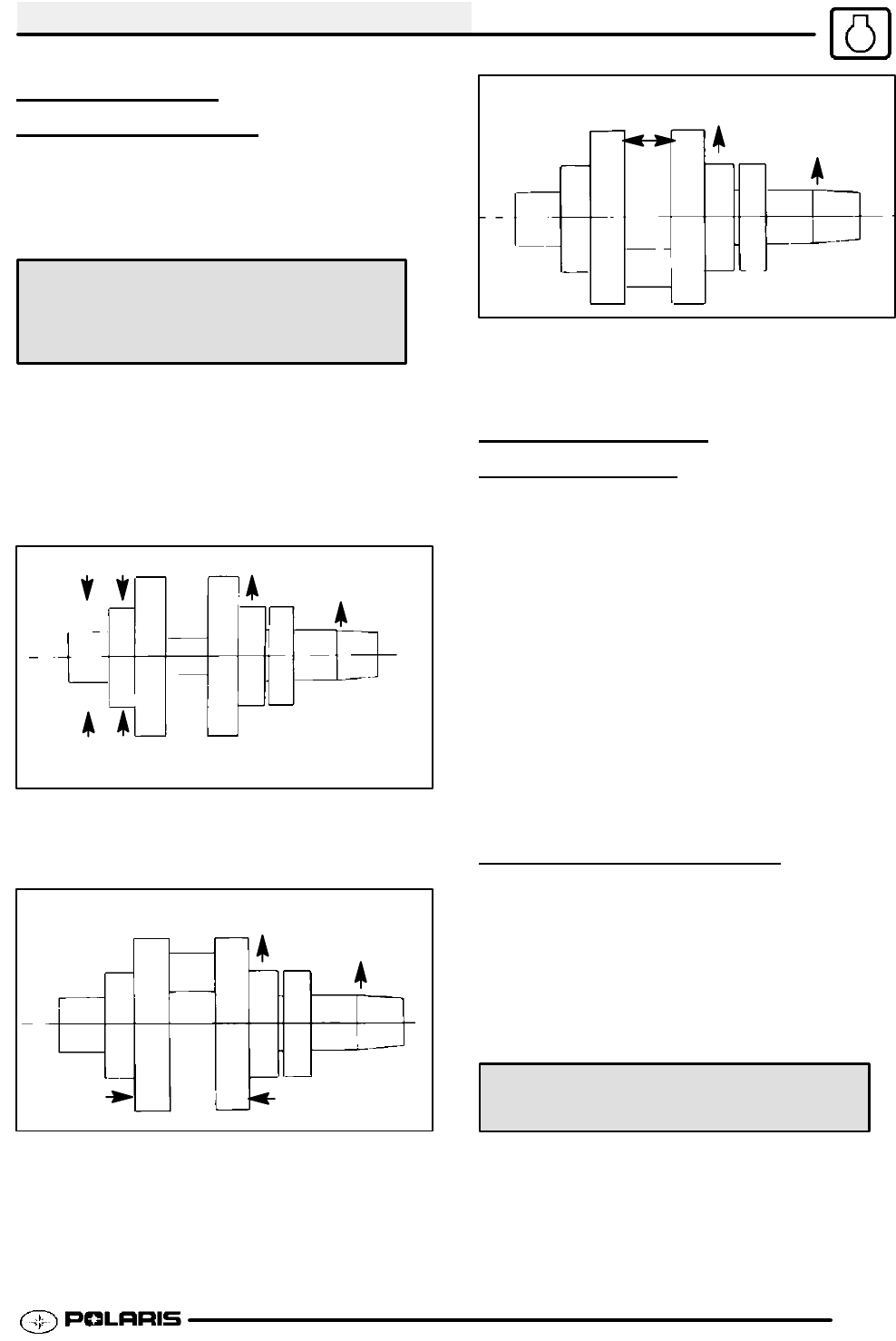

STRAIGHTENING

Lubricate the bearings and clamp the crankshaft

securely in the crankshaft alignment fixture. Refer to

the illustrations below.

Crankshaft Alignment Fixture

(PN 2870569)

NOTE:The rod pin position in relation to the dial

indicator position tells you what action is required to

straighten the shaft.

1. To correct a situation like the one shown in the

illustration, strike the shaft at point A with a brass

hammer.

A

B

HIGH .004 (.1mm)

HIGH .004 (.1mm)

SUPPORT CRANKSHAFT

HERE.

2. To correct a situation like the one shown in the

illustration, squeeze the crankshaft at points A.

(Use tool from alignment kit).

AA

HIGH .002 (.05mm)

HIGH .005 (.13mm)

3. If the crank rod pin location is 180_ from the dial

indicator (opposite that shown above), it will be

necessary to spread the crankshaft at position A

as shown in the illustration at right. When

rebuilding and straightening a crankshaft, runout

must be as close to zero as possible.

A

HIGH .002 (.05mm)

HIGH .005 (.13mm)

A

NOTE: Maximum allowable runout is .0024I

ES50PL ENGINE

LUBRICA

TION

Oil Type:

Polaris PS--4 Synthetic (PN 2874414)

Capacity:

Approximately 2.25 U.S. Quarts (2.1L)

Filter:

PN 3084963

Drain Plug / Screen Fitting:

14.8--17 ft. lbs. (20--23 Nm)

(If fitting is removed, follow

oil pump priming procedure).

Oil Pressure Specification:

20 PSI @ 5500 RPM, Polaris PS--4 Synthetic

(Engine Hot)

OIL PRESSURE TEST

1. Remove blind plug on front right oil filter cover.

2. Insert a 1/8 NPT oil pressure gauge adaptor and

attach the gauge.

3. Start engine and allow it to reach operating

temperature, monitoring gauge indicator.

NOTE: Use only Polaris PS 4 Synthetic Engine

Lubricant (PN 2874414).

Oil Pressure at 5500 RPM (Engine Hot):

Standard: 20 PSI

Minimum: 12 PSI

Enfocus Software - Customer Support