ENGINE

3.34

WATE R PUMP MECHANICAL

SEAL REMOV

AL

W ater Pump Mechanical Seal

Puller: (PN 2872105)

Replacement T--Handle:

(PN 2872106)

CAUTION:

Improper or careless use of this tool or

procedure can result in a bent water pump

shaft. P ump shaft replacement r equires

engine removal and crankcase separa-

tion. Use caution while performing this

procedure. Make sure that the puller is

parallel to the shaft at all times. Do not

place side loads on the water pump shaft

or strike the puller or shaft in any way.

The Water Pump Mechanical Seal Puller allows a

technician to replace the seal on ES50PL engines

without removing the engine and splitting the cases.

NOTE: This removal process dismantles the seal,

making it unusable for reinstallation.

1. After the coolant has been drained, remove the

water pump cover, impeller and the sealing

washer. (Ill. 1)

Ill. 1

Impeller

Sealing Washer

Mechanical Seal

2. Slide the main puller body over the outer portion

of the mechanical seal as shown in Ill. 2 and turn

T-Handle clockwise until it contacts water pump

shaft. Continue rotating until outer portion of

mechanical seal is separated from the metal seal

body.

Ill. 2

T-Handle

Main Puller Body

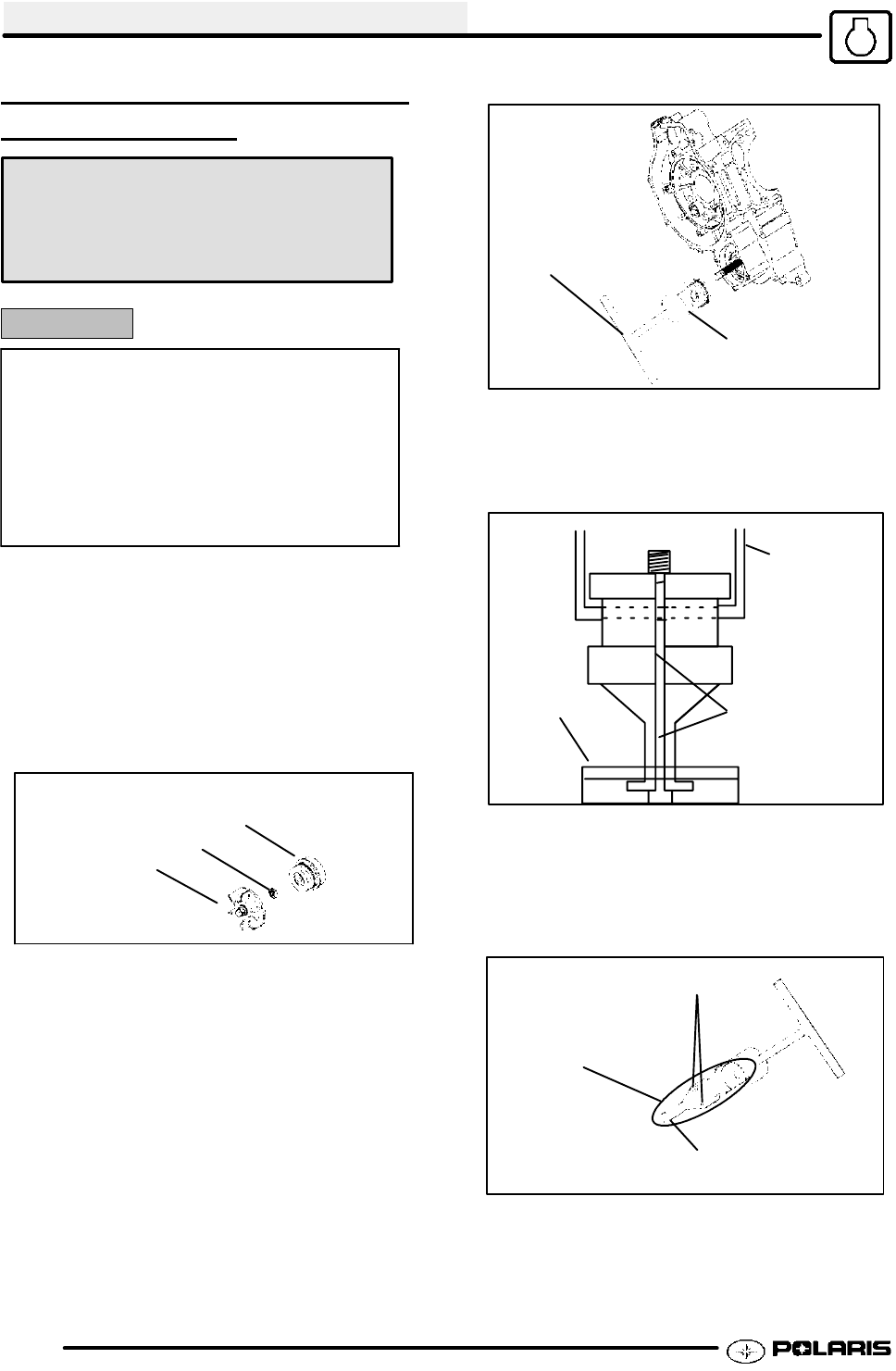

3. Insert the puller legs between the water pump

drive shaft and the remaining portion of the

mechanical seal. Attach the puller legs to the

main puller body. (Ill. 3)

Ill. 3

Position the split

90q to opening

on main puller

body

Main puller

body

Seal

4. Ensure that the split between the puller legs are

fully supported by the main body of the tool (Ill 3).

5. Tighten the hex socket screws on the puller legs

sufficiently so the lip of the puller legs will grasp

the mechanical seal. Ill. 4

Hex Socket Screws

Ill. 4

Lip must grasp inside

of mechanical seal.

Puller Legs

Enfocus Software - Customer Support