BRAKES

6.18

REAR BRAKE DISC

INSPECTION

1. Visually inspect disc for scoring, scratches, or

gouges. Replace the disc if any deep scratches

are evident.

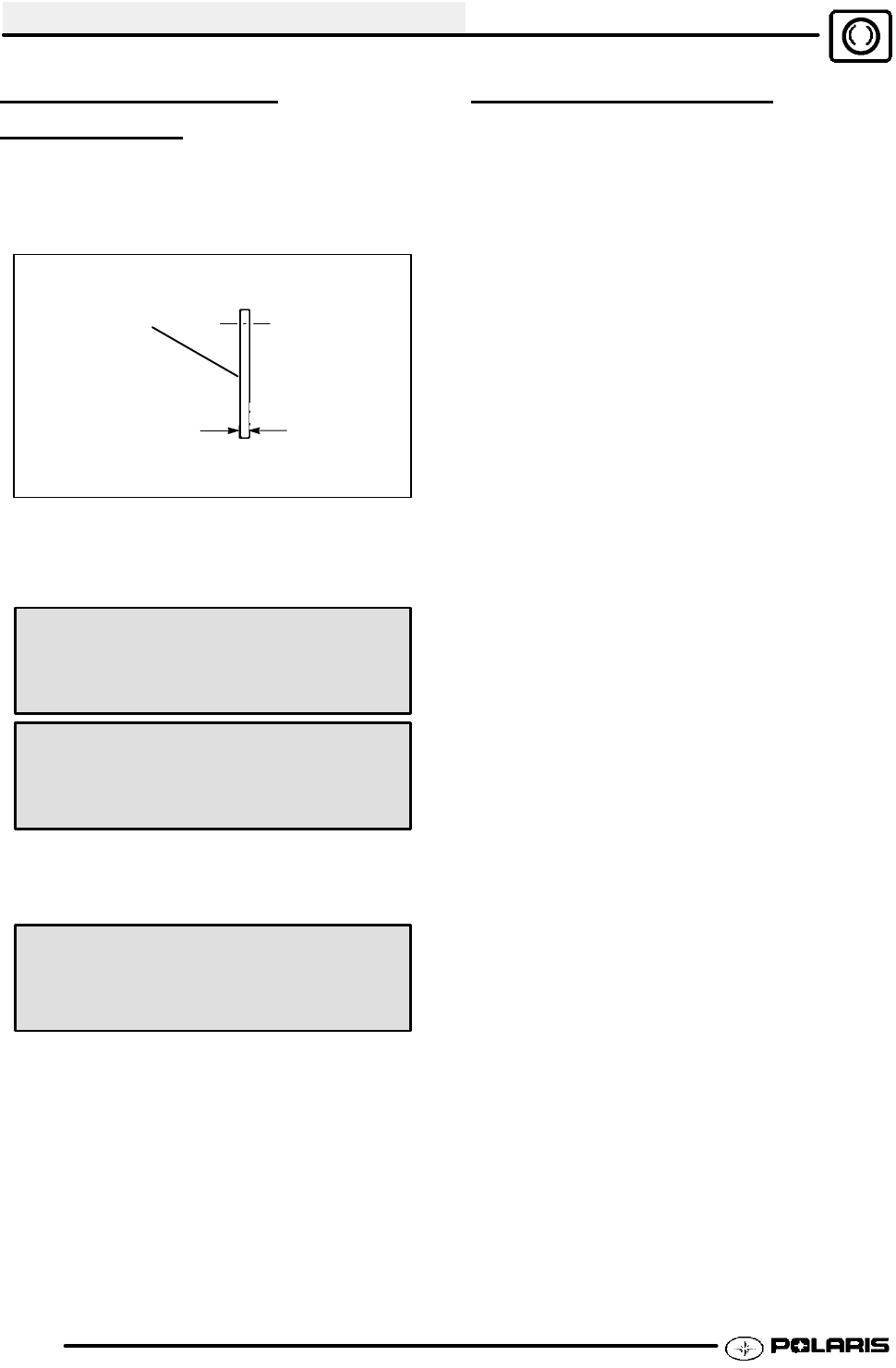

Measure

Thickness

Rear Brake

Disc

2. Usea0-1s micrometer and measure disc

thickness at 8 different points around perimeter of

disc. Replace disc if worn beyond service limit.

Brake Disc Thickness

Service Limit .140s / 3.556 mm

New .150-.164s (3.810-4.166 mm)

Brake Disc Thickness Variance

Service Limit .002s (.051 mm)

difference between measurements.

3. Mount dial indicator and measure disc runout.

Replace the disc if runout exceeds specifications.

Brake Disc Runout

Service Limit .010s (.25 mm)

TROUBLESHOOTING

Brakes Squeal

G Dirty/contaminated friction pads

G Improper alignment

G Worn disc

G Worn disc splines

G Glazed brake pads

Poor Brake Performance

G Air in system

G Water in system (brake fluid

contaminated)

G Caliper/disc misaligned

G Caliper dirty or damaged

G Brake line damaged or lining

ruptured

G Worn disc and/or friction pads

G Incorrectly adjusted lever

G Incorrectly adjusted stationary pad

G Worn or damaged master cylinder or

components

G Improper clearance between lever

and switch

Lever Vibration

G Disc damaged

G Disc worn (runout or thickness

variance exceeds service limit)

G Caliper Overheats (Brakes Drag)

G Compensating port plugged

G Pad clearance set incorrectly

G Auxiliary brake pedal incorrectly

adjusted

G Brake lever or pedal binding or

unable to return fully

G Parking brake left on

G Residue build up under caliper seals

G Operator riding brakes

Brakes Lock

G Alignment of caliper to disc

G Fluid overfill of the reservoir

G Stuck caliper piston

Enfocus Software - Customer Support