ENGINE

3.18

3. Check end of valve stem for flaring, pitting, wear

or damage (A).

A

B

4. Inspect split keeper groove for wear or flaring of

the keeper seat area (B). NOTE: The valves

cannot be re-faced or end ground. Valves must

be replaced if worn, bent, or damaged.

5. Measure diameter of valve stem with a

micrometer in three places and in two different

directions (six measurements total). Compare to

specifications.

Measure valve stem in

several places.

Valve Stem Diameter:

Intake: .2343-.2348I (5.950-5.965 mm)

Exhaust: .2341 -.2346I (5.945-5.960 mm)

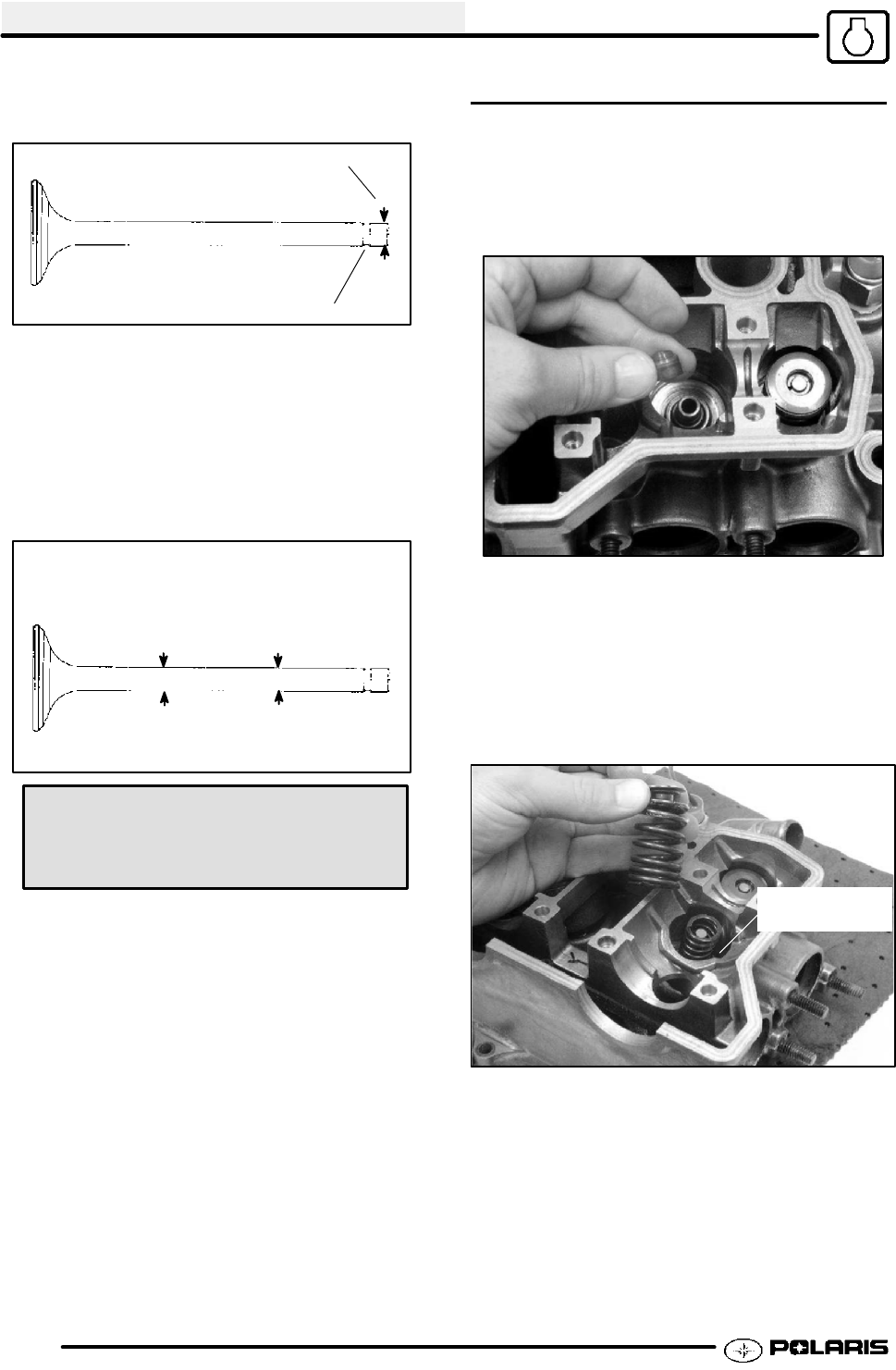

CYLINDER HEAD ASSEMBLY

CAUTION: Wear eye protection during assembly.

NOTE: Assemble the valves one at a time to maintain

proper order.

1. Install new valve seals on valve guides.

2. Apply engine oil to valve guides and seats.

3. Coat valve stem with assembly lube.

4. Install valve carefully with a rotating motion to

avoid damaging valve seal.

5. Install spring washers. Dip valve springs and

retainer in clean engine oil and install springs with

closely spaced coils toward the cylinder head.

Spring washer

located below

Enfocus Software - Customer Support