ENGINE

3.22

5. The oil control ring is a three piece design consisting

of a top and bottom steel rail and center expander

section. Remove the top rail first followed by the

bottom rail, then remove the expander. For

installation, refer to Page 3.35.

CYLINDER INSPECTION

1. Remove all gasket material from the cylinder

sealing surfaces.

2. Inspect the top of the cylinder for warpage using a

straight edge and feeler gauge.

Cylinder Warpage:

.002s (.05 mm)

3. Inspect cylinder for wear, scratches, or damage.

1/2s Down From Top of Cylinder

1/2s Up From Bottom

X

X

Y

Y

X

Y

4. Inspect cylinder for taper and out of round with a

telescoping gauge or a dial bore gauge. Measure

in two different directions, front to back and side to

side, on three different levels (1/2s down from top,

in the middle, and 1/2s up from bottom).

5. Record measurements. If cylinder is tapered or

out of round beyond specification, the cylinder

must be replaced.

Cylinder Taper

Limit: .002I (.05 mm) Max.

Cylinder Out of Round

Limit: .002I (.05 mm) Max.

Standard Bore Size:

3.9055-3.9062I (99.20-99.22mm)

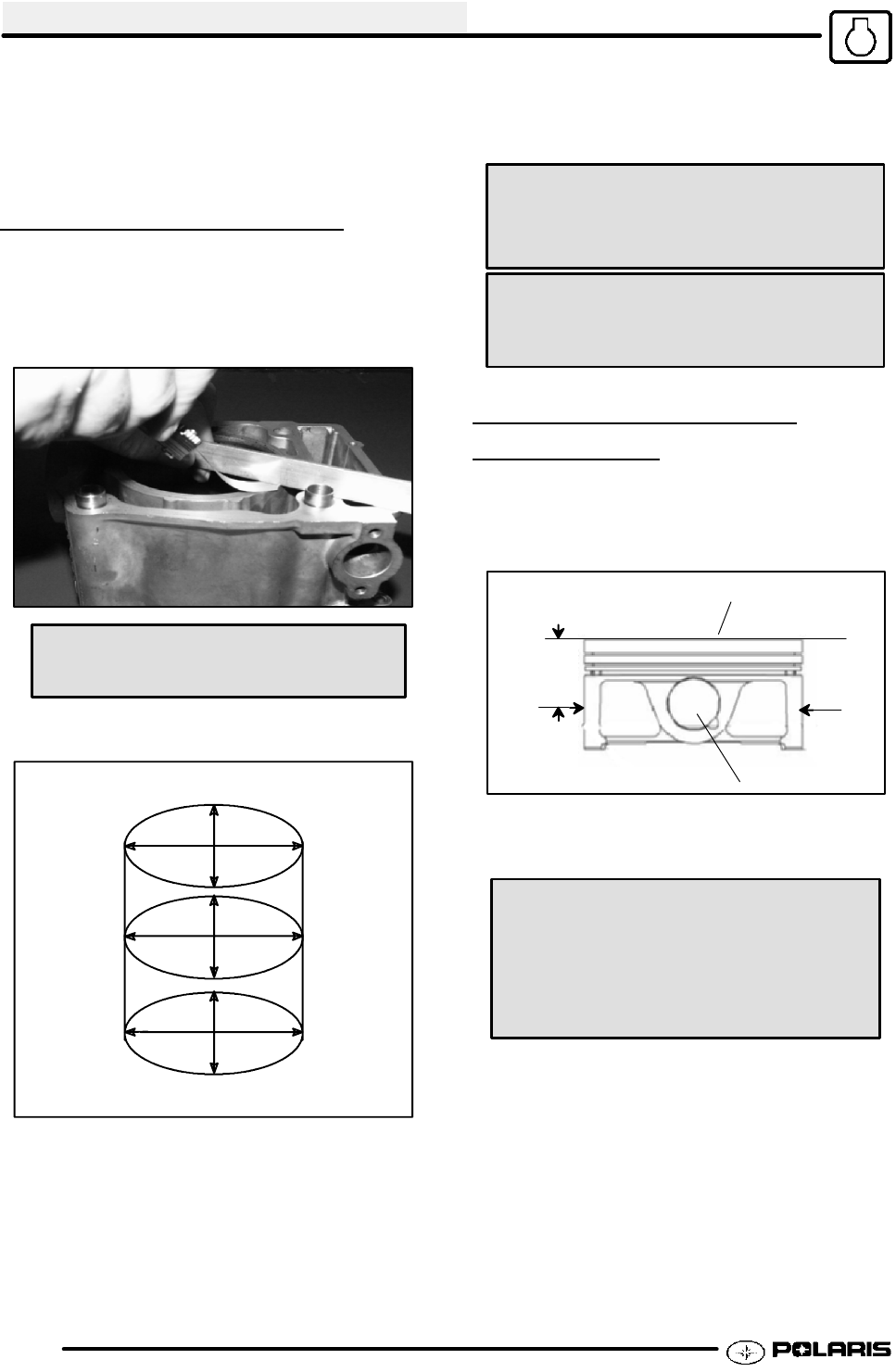

PISTON-TO-CYLINDER

CLEARANCE

1. Measure piston outside diameter at a point 40 mm

down from the top of the piston at a right angle to

the direction of the piston pin.

40 mm

Piston

Piston Pin

2. Subtract this measurement from the maximum

cylinder measurement obtained in Step 5.

Piston to Cylinder Clearance

Std: 0018 -- .0025I (.046 -- .065 mm)

Piston O.D.:

Std: 3.9037-3.9040I (99.155-99.170mm)

Enfocus Software - Customer Support