BODY / STEERING / SUSPENSION

5.26

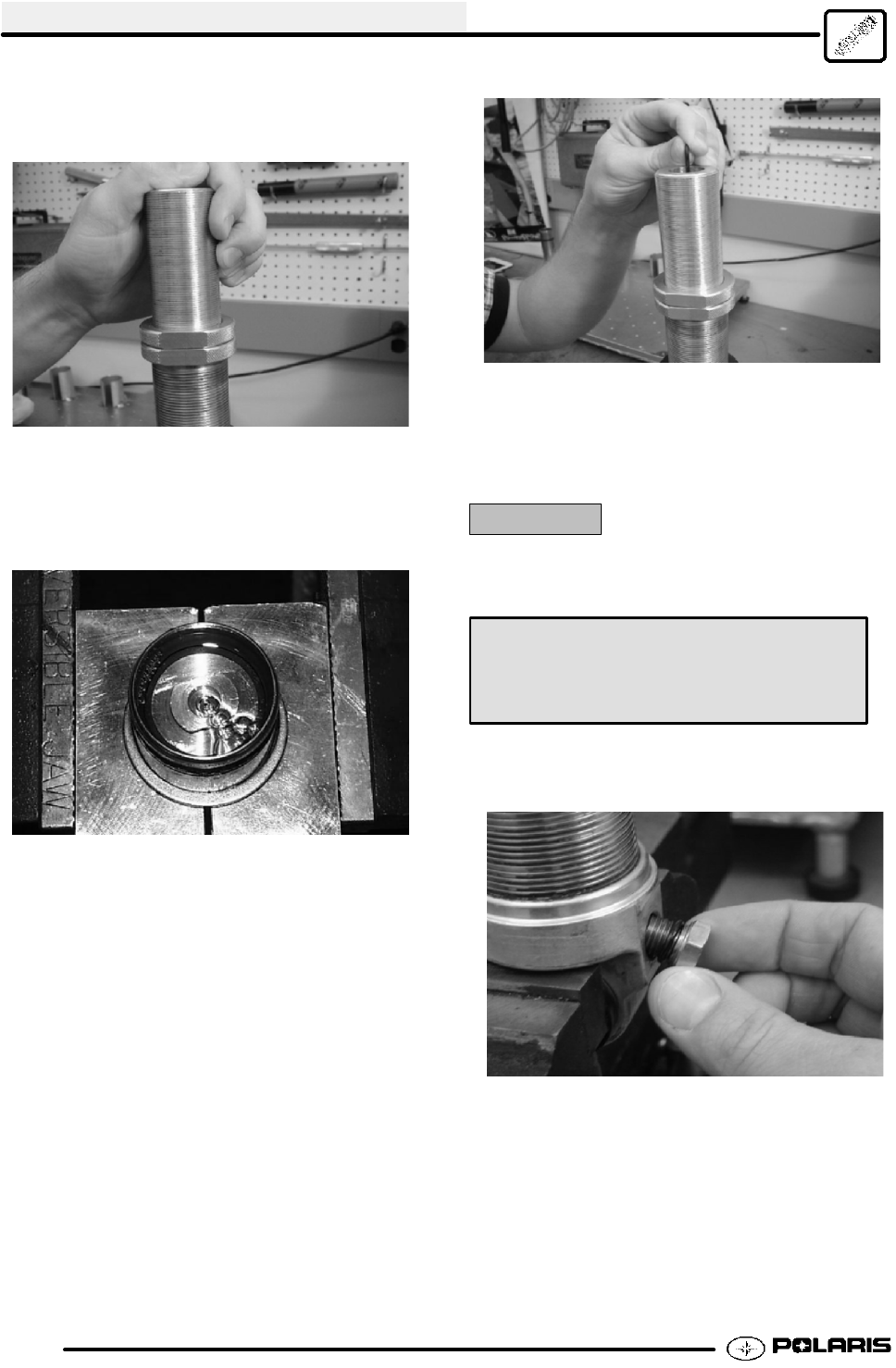

12. Insert IFP tool and slowly push IFP to specified

depth. Place a shop towel over the end of IFP tool

to catch any spilled shock oil.

13. With the IFP set and the bleeder screw removed,

slowly stroke shock to force air through piston

oriface. Move the shock body slowly to prevent

aeration of the oil. Allow all air to purge through

the bleeder screw hole.

14. Install the bleeder screw with a new O-ring and

tighten securely, using the flats on the tool to

prevent the IFP from turning. Pour out excess oil.

It is not necessary to completely clean all oil from

the nitrogen chamber, a small amount of oil will

lubricate the IFP. Verify the proper IFP depth to

within r .025s (.63mm) with a dial caliper. Be sure

to measure to the flat portion of the IFP, not to the

tapered outer edge.

15. Reinstall body cap with a new O-ring and tighten

by hand. Mount shock with body cap end down in

the soft jaws of a vise. Torque bearing cap to 8-10

ft. lbs. (11-14 Nm). This will also tighten the body

into the body cap.

CAUTION:

Do not over tighten or damage to the bearing may

result.

Bearing Cap Torque

8-10 ft. lbs. (11-14 Nm)

16. Install pressurizing valve with new O-ring and

tighten securely.

Enfocus Software - Customer Support