3.36

ENGINE

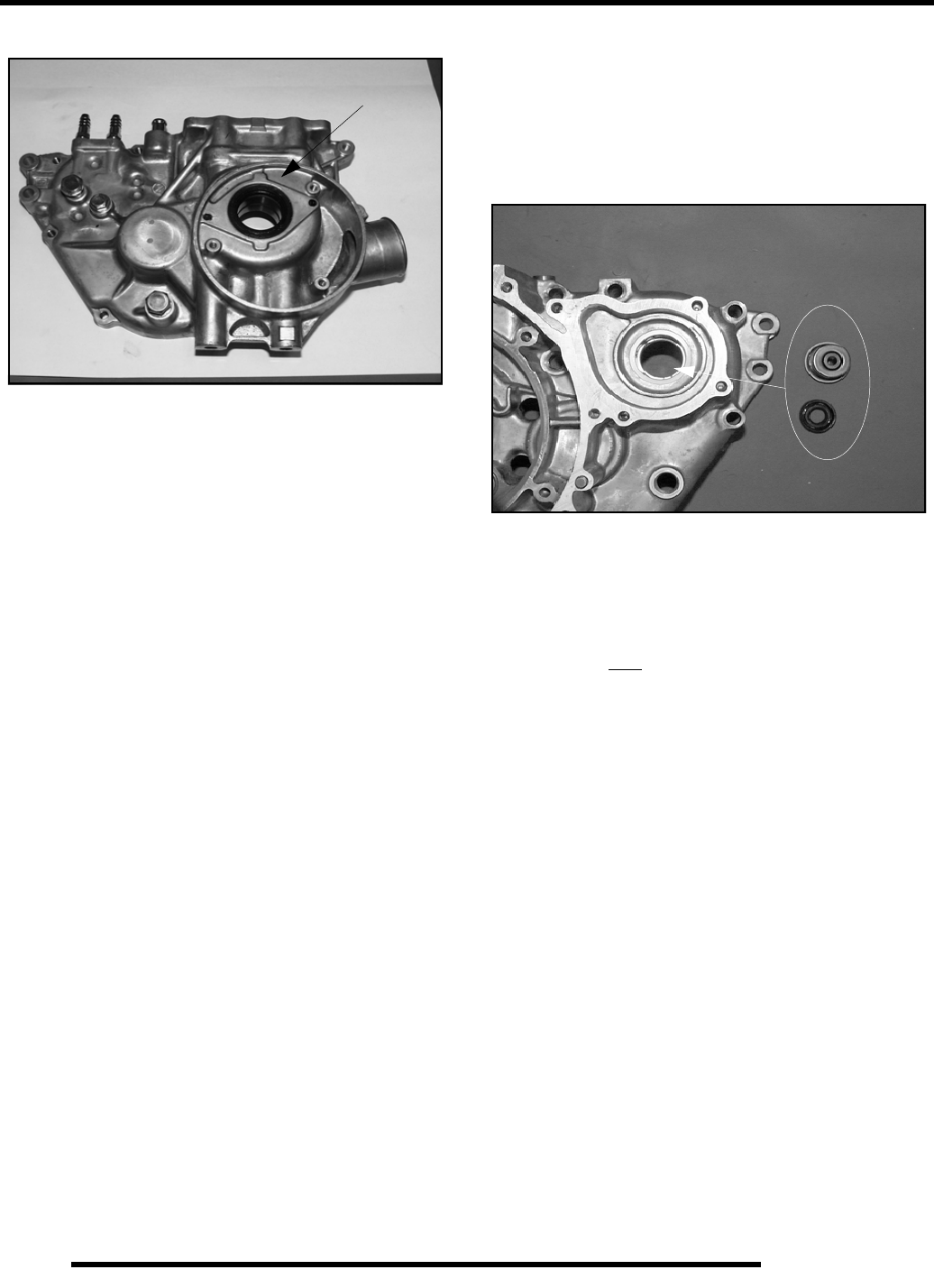

Crankcase Bearing Inspection

1. Remove the seal from the PTO side crankcase.

2. Inspect the crankshaft main bearings, balancer shaft

bearings, and pump shaft bearing.

NOTE: Due to extremely close tolerances and minimal

wear, the bearings must be inspected visually, and by

feel. Look for signs of discoloration, scoring or galling.

Turn the inner race of each bearing. The bearings should

turn smoothly and quietly. The outer race of each bearing

should fit tightly in the crankcase. The inner race should

be firm with minimal side to side movement and no

detectable up and down movement.

3. Support the crankcase and drive or press the main bearings

out of each crankcase.

4. To remove balancer shaft bearings and pump shaft bearing

use a blind hole bearing puller.

NOTE: Bearings are stressed during the removal

process and should not be re-used!

Pump Shaft Oil Seal/Water Pump Mechanical

Seal Removal (Engine Disassembled)

NOTE: The water pump mechanical seal can be

removed without removing the engine. Refer to Water

Pump Mechanical Seal Installation.

Replace the pump shaft seal and water pump mechanical

seal whenever the crankcase is disassembled.

1. Remove the pump shaft bearing from the Magneto (right

hand) side crankcase.

2. Pry out the oil seal, noting the direction of installation with

the spring side facing IN (toward inside of case).

3. Drive the water pump mechanical seal out of the crankcase

from inside to outside. Note: The new mechanical seal must

be installed after

the crankcases are assembled, using a

special tool. See Mechanical Seal Installation.

Crankcase Inspection

1. Remove all traces of gasket sealer from the crankcase

mating surfaces. Inspect the surfaces closely for nicks,

burrs or damage.

2. Check the oil pump and oil passage mating surfaces to be

sure they are clean and not damaged.