4.41

CARBURETOR - SPORTSMAN 450

4

Carburetor Inspection

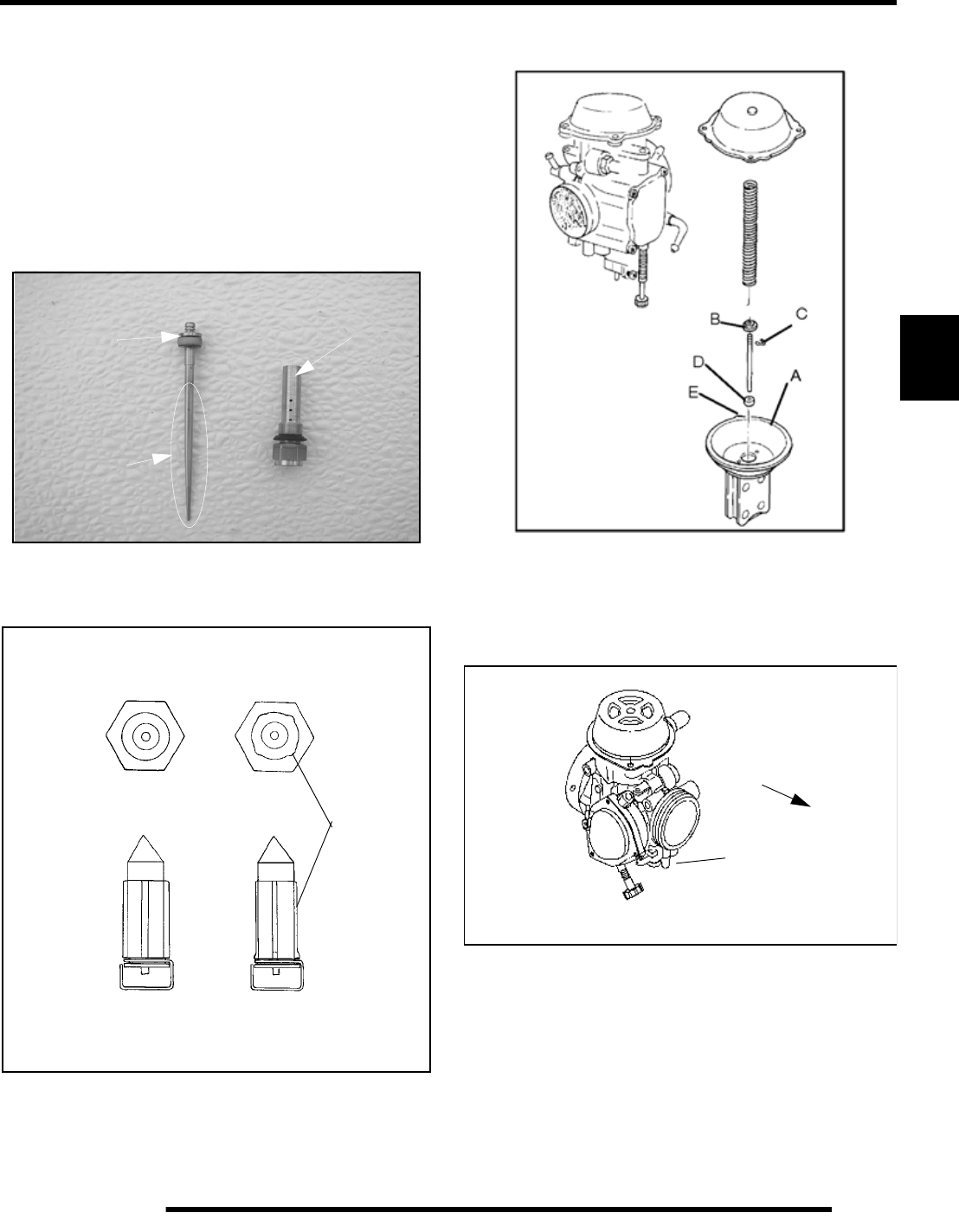

1. Inspect jet needle and needle jet for wear. Look for

discoloration, shiny spots, or an area that looks different

than the rest of the needle. The middle to upper portion of

the needle contacts the needle jet and is the most likely

wear point. If jet needle shows signs of wear replace both

the needle and needle jet to prevent a rich condition. TIP:

A worn needle jet is difficult to spot. To check, slide a

slightly larger new jet needle into the needle jet and hold it

to a light source. Light will be visible between the needle

and needle jet if it is worn.

2. Inspect the inlet needle tapered surface for any sign of wear

or damage. Be sure the spring loaded pin is free moving and

returns freely when pushed. The inlet needle and seat

should be pressure tested after assembly.

Carburetor Assembly

Inspect the diaphragm (A) for holes, deterioration, or damage.

Make sure the diaphragm is pliable but not swollen. The

diaphragm should fit properly in the carburetor body. Replace

diaphragm assembly if diaphragm is damaged.

1. Replace parts in proper order. The spring seat (B) is

stepped and must be placed on TOP of “E” Clip (C).

Spacer washer (D) must be installed below the E–Clip.

Refer to parts manual for more information.

2. Be sure the tab (E) on outer edge of diaphragm is positioned

properly in the carburetor body.

3. Install the pilot mixture screw, spring, washer, and O–ring

as an assembly. Lubricate the O–Ring with oil or light

grease before installation. CAUTION: Do not damage the

O–ring during installation. Turn the screw in until it lightly

contacts the seat. Back out the specified number of turns.

NOTE: The final pilot (idle) mixture must be adjusted with

Inspect this

area

Jet Needle

Needle Jet

Good Condition

Worn, Deposits

Seat

Needle

Wear areas

FRONT

(Engine)

Pilot Screw