3.29

ENGINE

3

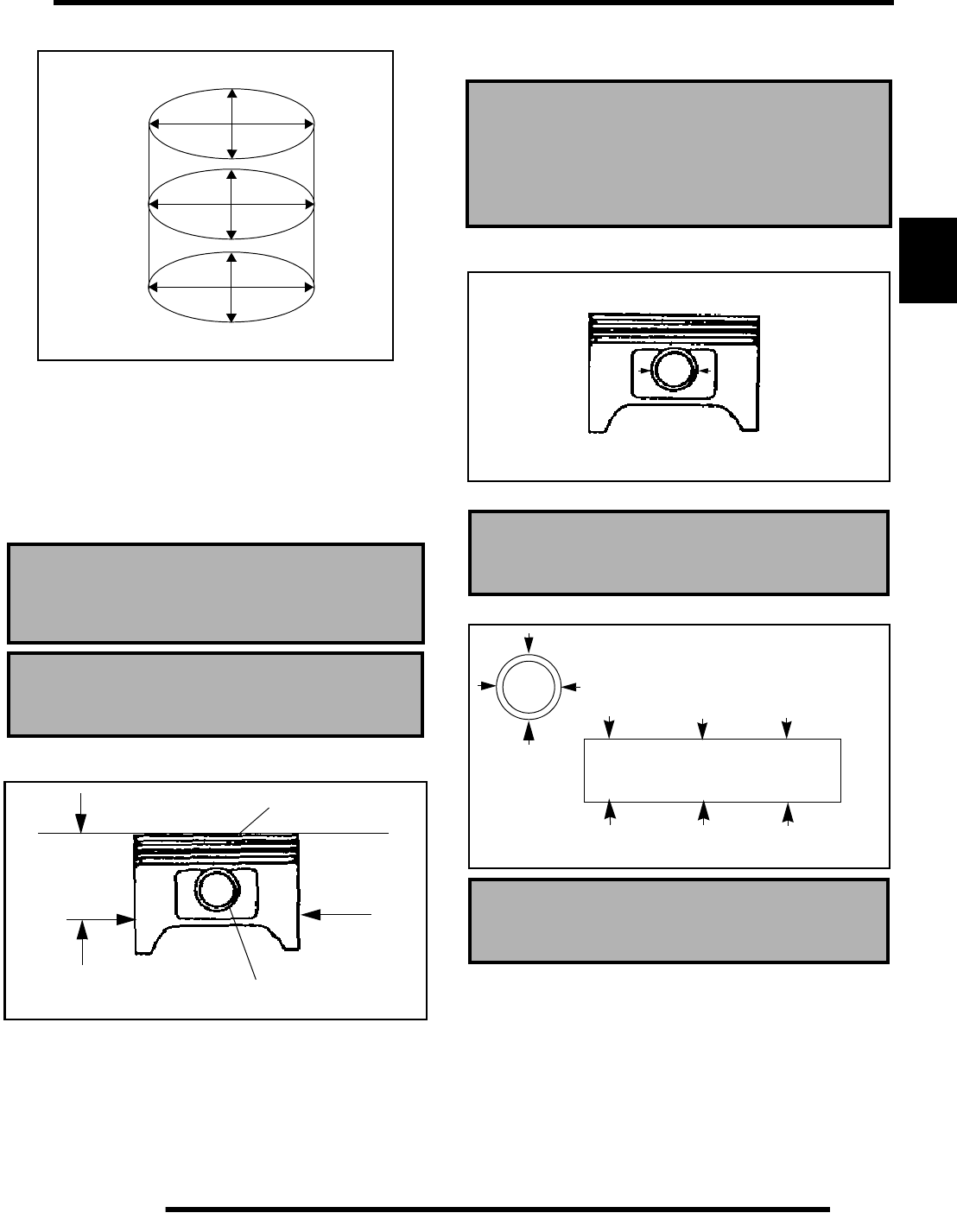

3. Inspect cylinder for wear, scratches, or damage.

4. Inspect cylinder for taper and out of round with a

telescoping gauge or a dial bore gauge. Measure in two

different directions, front to back and side to side, on three

different levels (1/2” down from top, in the middle, and 1/

2” up from bottom).

5. Record measurements. If cylinder is tapered or out of round

beyond .002, the cylinder must be re-bored oversize or

replaced.

Piston-to-Cylinder Clearance

1. Measure piston outside diameter at a point 40 mm down

from the top of the piston at a right angle to the direction

of the piston pin.

2. Subtract this measurement from the maximum cylinder

measurement obtained in Step 5 above.

Piston/Rod Inspection

1. Measure piston pin bore.

Cylinder Taper

Limit: .002 Max.

Cylinder Out of Round

Limit: .002 Max.

Standard Bore Size:

3.6221-3.6228” (92.00 - 92.012 mm)

1/2” Down From Top of Cylinder

1/2” Up From Bottom

X

X

X

Y

Y

Y

Piston Pin

Piston

40 mm

Piston to Cylinder Clearance

Std: .0006- .0018” (.015- .045 mm)

Piston O.D.:

Std: 3.6204- 3.6215” (91.970-91.985 mm)

Piston Pin Bore:

.9055-.9057” (23.0-23.006 mm)

Piston Pin O.D.

.9053-.9055” (22.994-23.0 mm)

Piston Pin Bore

Piston Pin Measurement Locations