3.23

ENGINE

3

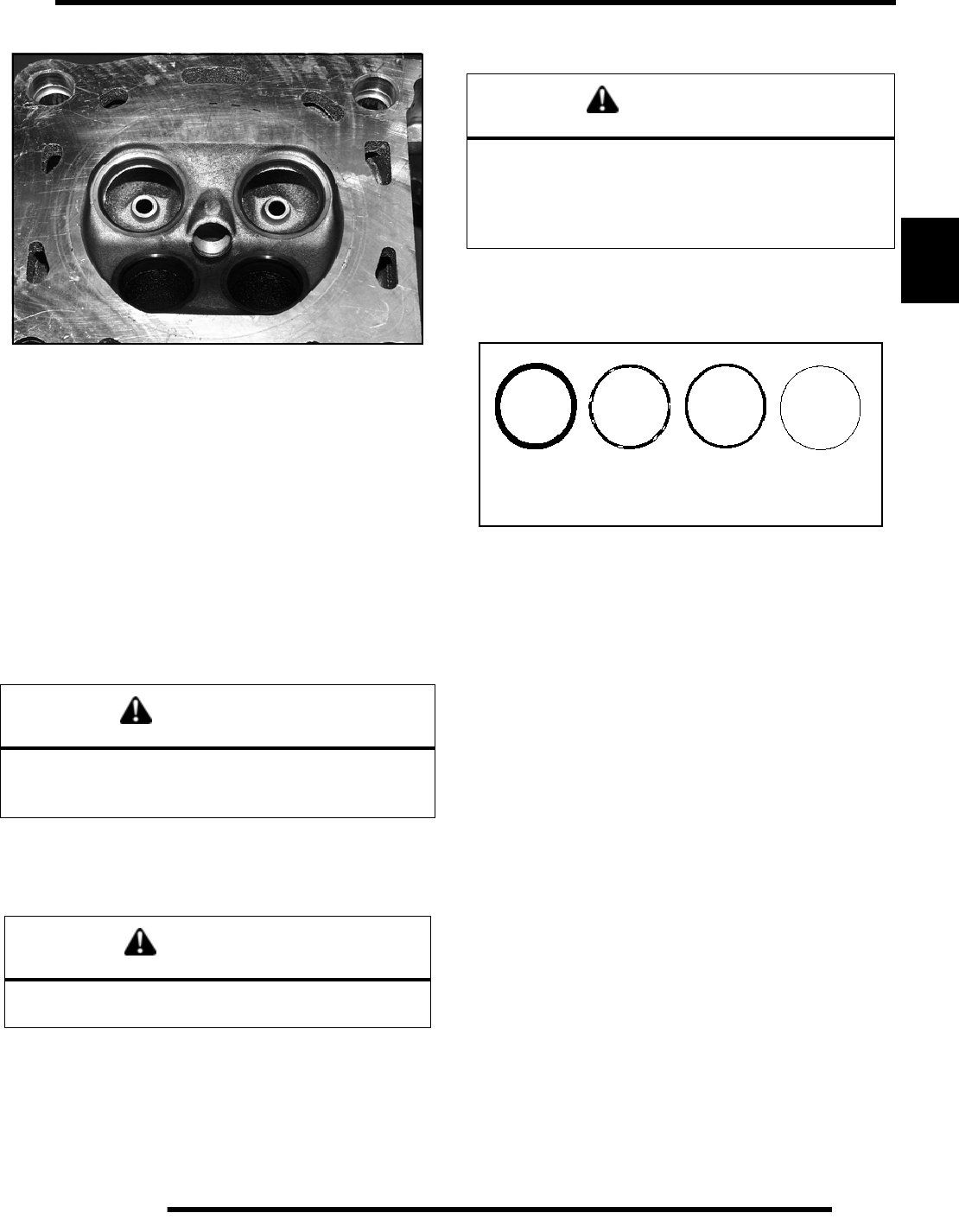

Combustion Chamber

Clean all accumulated carbon deposits from combustion

chamber and valve seat area with a soft wire brush.

Valve Seat ReconditionING

Valve Seat Inspection

Inspect valve seat in cylinder head for pitting, burnt spots,

roughness, and uneven surface. If any of the above

conditions exist, the valve seat must be reconditioned. If

the valve seat is cracked the cylinder head must be

replaced.

Cylinder Head Reconditioning

NOTE: Servicing the valve guides and valve seats

requires special tools and a thorough knowledge of

reconditioning techniques. Follow the instructions

provided in the cylinder head service tool kit.

Valve Guide Removal/Installation

1. Remove all carbon deposits from the combustion chamber,

valve seat and valve guide area before attempting to

remove valve guides.

2. Place new valve guides in a freezer for at least 15 minutes

while heating cylinder head.

3. Heat cylinder head in an oven or use a hot plate to bring

cylinder head temperature to 212

o

F (100

o

C).

Follow the manufacturers instructions provided with the

valve seat cutters in the Valve Seat Reconditioning Kit (PN

2200634). Abrasive stone seat reconditioning equipment

can also be used. Keep all valves in order with their

respective seat.

NOTE: Valve seat width and point of contact on the

valve face is very important for proper sealing. The valve

must contact the valve seat over the entire

circumference of the seat, and the seat must be the

proper width all the way around. If the seat is uneven,

compression leakage will result. If the seat is too wide,

seat pressure is reduced, causing carbon accumulation

and possible compression loss. If the seat is too narrow,

heat transfer from valve to seat is reduced and the valve

may overheat and warp, resulting in burnt valves.

1. When thoroughly heated, place cylinder head on blocks of

wood which will allow the old guides to be removed.

2. Using valve guide driver, drive guides out of the cylinder

head from the combustion chamber side. Be careful not to

damage guide bore or valve seat when removing guides.

CAUTION

Wear eye protection when performing cylinder head

service. Valve guide replacement will require heating of

the cylinder head. Wear gloves to prevent burns.

CAUTION

Carbon deposits are extremely abrasive and may

damage the valve guide bore when guides are removed.

CAUTION

Do not use a torch to heat cylinder head or warpage may

result from uneven heating. Head temperature can be

checked with a pyrometer or a welding temperature

stick. Wear the appropriate safety equipment for

working with heated metal.

Too Uneven Good Too

Wide

Narrow