3.44

ENGINE

Piston Installation

1. Clean the gasket surfaces on the cylinder and crankcase.

Remove all traces of old gasket material.

2. Make sure the cylinder mounting bolt holes are clean and

free of debris.

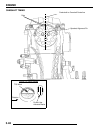

3. Install a new circlip on one side of the piston with the end

gap facing up or down, and tang outward.

4. Apply clean engine oil to the piston rings, ring lands, piston

pin bore, piston pin, and piston skirt. Lubricate the

connecting rod (both ends), balancer drive gear, and

crankshaft main bearing area.

5. Install the piston on the connecting rod with the arrow or :

mark facing the magneto (RH) end of the crankshaft. The

piston pin should be a push fit in the piston.

6. Install the other circlip with the gap facing up or down and

tang outward. (See Caution with Step 3 above). Push the

piston pin in both directions to make sure the clips are

properly seated in the groove.

Cylinder Installation

7. Place the dowel pins in the crankcase and install a new

cylinder base gasket.

8. Position the Piston Support Block (PN 2870390) (A)

beneath the piston skirt to support the piston during

cylinder installation.

9. Apply clean engine oil to a ring compressor and install the

compressor following manufacturers instructions.

CAUTION

Circlips become deformed during the removal process.

Do not re-use old circlips. Do not compress the new clip

more than necessary upon installation to prevent loss of

radial tension. Severe engine damage may result if

circlips are re-used or deformed during installation.

Tang Outward

or :

Mag

CAUTION

Make sure the oil control ring upper rail tab is

positioned properly in the notch of the piston. Verify

all ring end gaps are correctly located.

A