10.31

ELECTRICAL

10

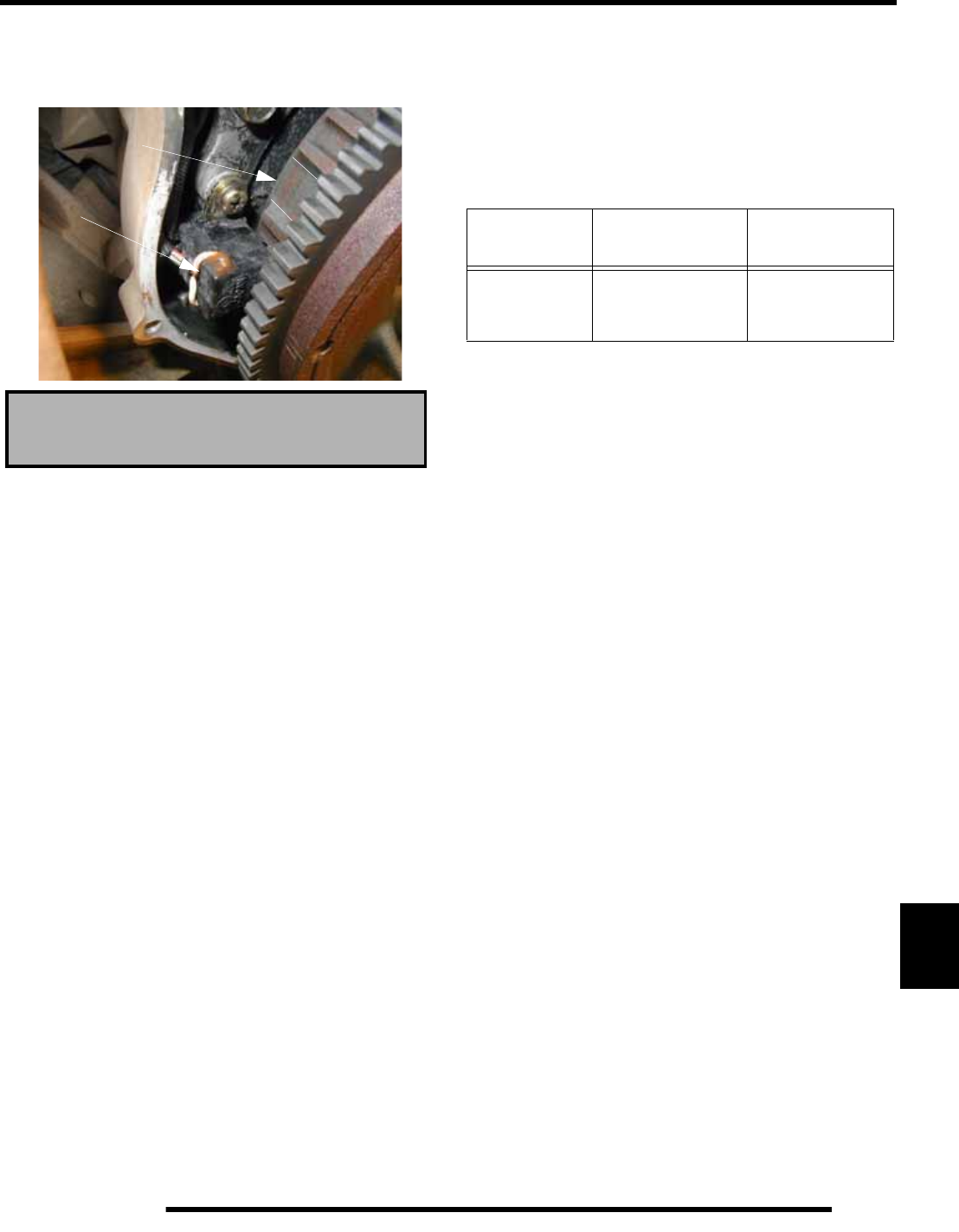

Crankshaft Position Sensor Gap

Measure trigger coil gap with a feeler gauge. The gap should be

0.4 - 1.2 mm (0.015 - .047 in.).

Ignition Troubleshooting

No Spark, Weak, or Intermittent Spark

• Spark plug gap incorrect

• Fouled spark plug

• Faulty spark plug cap or poor connection to high

tension lead

• Related wiring loose, disconnected, shorted, or

corroded

• Engine Stop switch or ignition switch faulty

• ETC switch misadjusted or faulty

• Wire harness or connections wet, corroded

• Poor ignition coil ground (e.g. coil mount loose or

corroded)

• Incorrect wiring (inspect color coding in connectors

etc)

• Faulty ignition coil winding (measure resistance of

primary and secondary)

• Sheared flywheel key

• Flywheel loose or damaged

• Faulty ECU

Ignition Output Test Using Gap Tester

Re-connect all wires. Disconnect spark plug wire from the spark

plug. Connect gap tester lead to engine ground and the other to

the ignition coil primary wire leading from the coil. Crank

engine and check output. Spark should jump a 1/4" (6mm) gap.

Reconnect coil wire.

Crankshaft Position Sensor Gap:

0.4 - 1.2 mm (0.015 - .047 in.)

CPS

Interrupt

Table 10-1:

TEST

CONNECT GAP

T

ESTER TO:

R

EADING

Spark Gap

Output Test

Spark plug lead and

ground

White/Blue spark

jumps 1/4" (6mm)

gap