4.17

FUEL INJECTION

4

Injector problems due to dirt or clogging are unlikely due to the

design of the injectors, the high fuel pressure, the use of filters

and the detergent additives in the gasoline. Symptoms that could

be caused by dirty/clogged injectors include rough idle,

hesitation/stumble during acceleration, or triggering of fault

codes related to fuel delivery. Injector clogging is usually

caused by a buildup of deposits on the director plate, restricting

the flow of fuel, resulting in a poor spray pattern. Some

contributing factors to injector clogging include; dirty air filters,

higher than normal operating temperatures, short operating

intervals and dirty, incorrect, or poor quality fuel. Cleaning of

clogged injectors is not recommended; they should be replaced.

Additives and higher grades of fuel can be used as a preventative

measure if clogging has been a problem.

Fuel Injector Resistance Test

If an injector is not operating, it can indicate either a bad injector,

or a wiring/electrical connection problem. Check as follows:

• Using an ohmmeter, test for continuity by placing the

test leads on each pin of the injector.

• Resistance specification is 12.0

±0.4 (20°C, 68°F)

Fuel Injector Replacement

1. Engine must be cool. Depressurize fuel system through

test valve in fuel rail.

2. Remove the front fender assembly and fuel tank.

3. Thoroughly clean the area around and including the throttle

body/manifold and the injectors.

4. Disconnect the fuel injector harness.

5. Remove the fuel rail mounting screws, doubler plate and

carefully loosen / pull the rail away from the injector.

6. Reverse the procedures to install the new injector and

reassemble. Use new O-rings any time an injector is

removed (new replacement injectors include new O-rings).

Lubricate the upper O-ring lightly with soapy water to aid

installation. The lower O-ring should remain dry. Torque

the fuel rail mounting screws to 5~7 ft. lbs. (6-9 Nm). Then

install the doubler plate and torque to 8~9.5 ft. lbs. (11-13

Nm).

CRANKSHAFT POSITION SENSOR

(CPS)

General Information

The engine speed sensor is essential to engine operation,

constantly monitoring the rotational speed (RPM) of the

crankshaft.

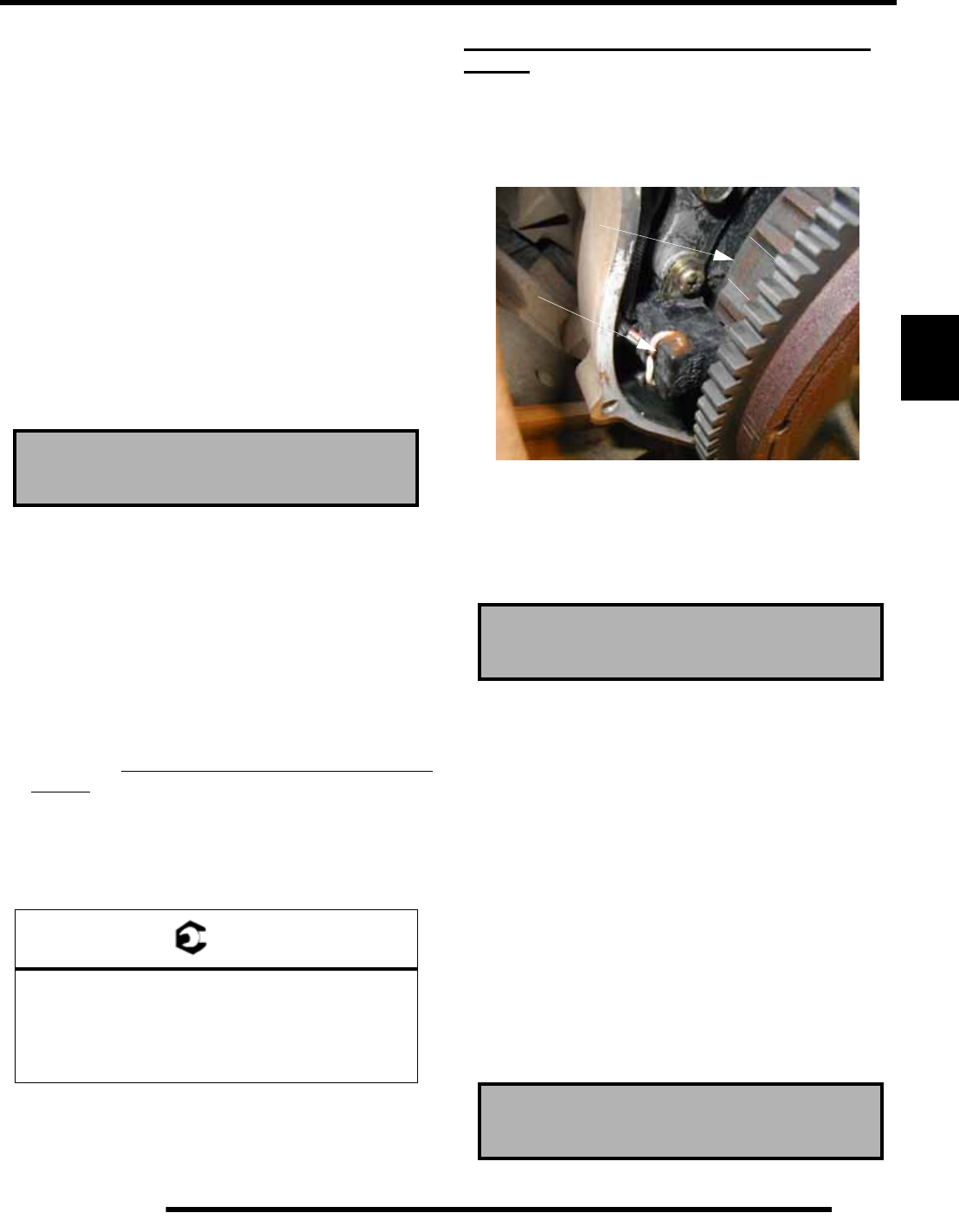

A ferromagnetic 36-1 ring gear is cast onto the flywheel. The

inductive crankshaft sensor is mounted 0.4 - 1.2 mm (0.015 -

.047 in.) away from this ring gear. During rotation, an AC pulse

is created within the sensor for each passing tooth. The tooth

gap creates an “interrupt” input signal, corresponding to specific

crankshaft position for PTO cylinder. This signal serves as a

reference for the control of ignition timing by the ECM.

Within one (1) revolution at start-up, the ECM calculates

crankshaft position from the time interval between the

consecutive pulses. Synchronization of the CPS, ECM and

MAP sensor takes place during the first two (2) revolutions each

time the engine is started. Once the engine is started, the ECM

monitors the MAP sensor for the engine intake stroke. The CPS

must be properly connected at all times. If the sensor fails or

becomes disconnected for any reason, the engine will quit

operating.

Crankshaft Position Sensor Test

The crankshaft position sensor is a sealed, non-serviceable

assembly. If fault code diagnosis indicates a problem within this

area, test and correct as follows:

1. Disconnect main harness connector from ECM.

2. Connect an ohmmeter between the pin terminals. A

resistance value of 185

20% at room temperature (20

C, 68 F) should be obtained. If resistance is correct, check

the mounting, air gap, toothed ring gear (damage, runout,

etc.), and flywheel key.

Injector Resistance Specification:

12.0 ±0.4 (20°C, 68°F)

= T

Fuel Rail Mounting Screws:

5~7 ft. lbs. (6-9 Nm)

Doubler Plate Screws

8~9.5 ft. lbs. (11-13 Nm)

Crankshaft Position Sensor Air Gap:

0.4 - 1.2 mm (0.015 - .047 in.)

Crankshaft Position Sensor Resistance:

185

± 20% @ (20° C , 68° F)

CPS

Interrupt