5.19

BODY / STEERING / SUSPENSION

5

Ball Joint Replacement

NOTE: Refer to the illustration on the previous page

for this procedure.

1. Loosen front wheel nuts slightly.

2. Elevate and safely support machine under footrest/frame

area.

3. Remove wheel nuts and wheels.

4. Remove cotter pin (A) from ball joint castle nut (B).

5. Remove castle nut (B) and separate A-arm (C) from ball

joint stud.

6. Remove screws (D) and ball joint retaining plate (E).

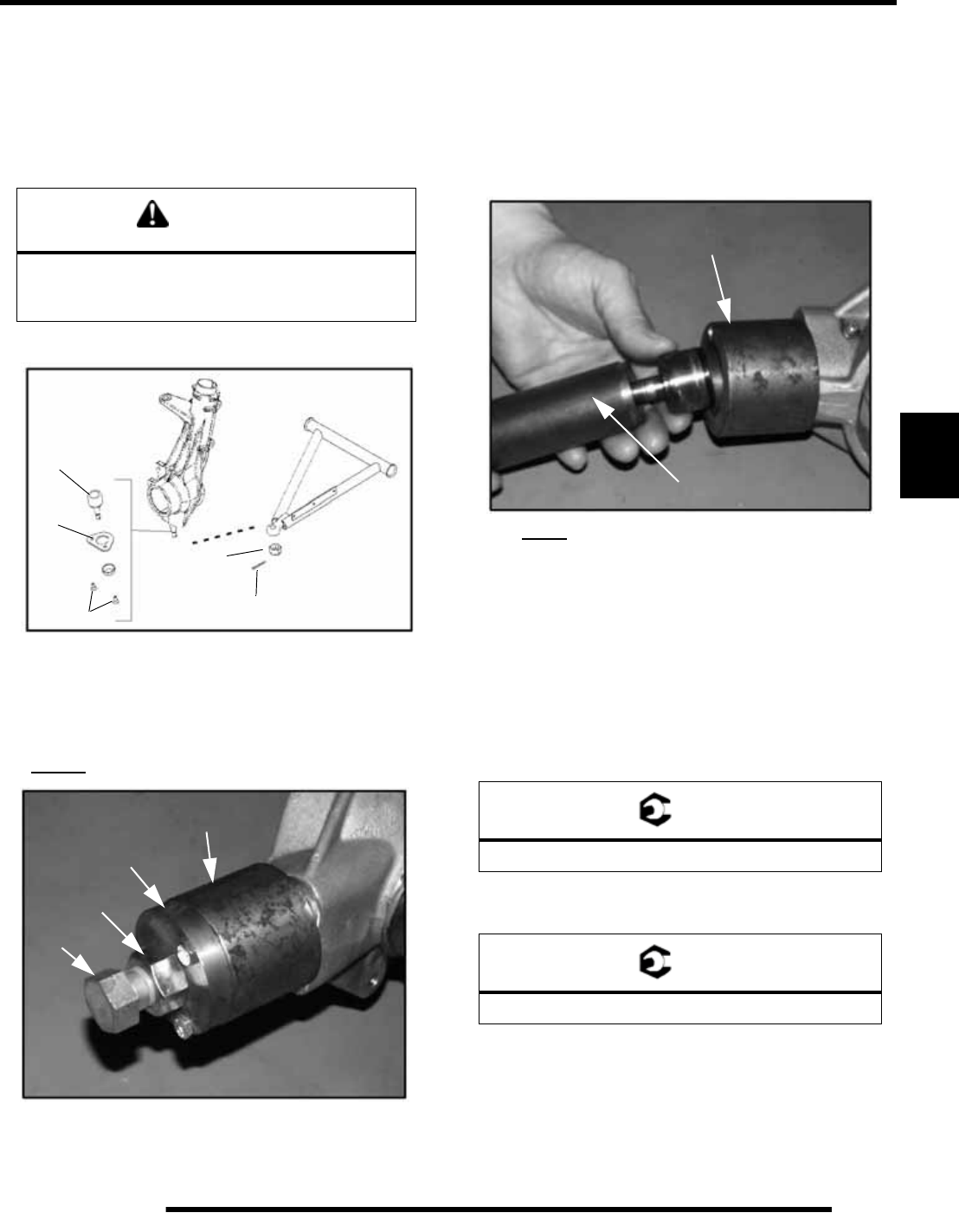

7. Use the Ball Joint Replacement Tool (PN 2870871),

remove

ball joint (F) from strut housing. Refer to photos.

8. Install puller guide (G) with extension cap (H).

9. Apply grease to extension cap and threads of puller bolt to

ease removal.

10. Thread bolt (J) with nut (I) onto ball joint stud as shown.

11. Apply heat to ease removal.

12. Hold bolt (J) and turn nut (I) clockwise until ball joint is

removed from strut housing.

13. To install

a new ball joint, Remove extension cap and

attach puller guide using short bolts provided in the kit.

14. Remove extension cap and attach puller guide using short

bolts provided in the kit.

15. Insert new ball joint (K) into driver (L).

16. Slide ball joint/driver assembly into guide.

17. Apply heat to ease installation.

18. Drive new joint into strut housing until fully seated.

19. Apply Loctite

242 (PN 2871949) to threads of retaining

plate screws or install new screws with pre-applied locking

agent. Torque screws to specification.

20. Install A-arm on ball joint and torque castle nut to

specification.

21. Reinstall cotter pin with open ends toward rear of machine.

CAUTION

Serious injury may result if machine tips or falls. Be

sure machine is secure before beginning this

service procedure.

F

E

D

A

B

G

H

I

J

= T

Retaining Screw Torque: 8 ft. lbs. (11 Nm)

= T

Castle Nut Torque: 25 ft. lbs. (35 Nm)

K

L