7.25

FINAL DRIVE

7

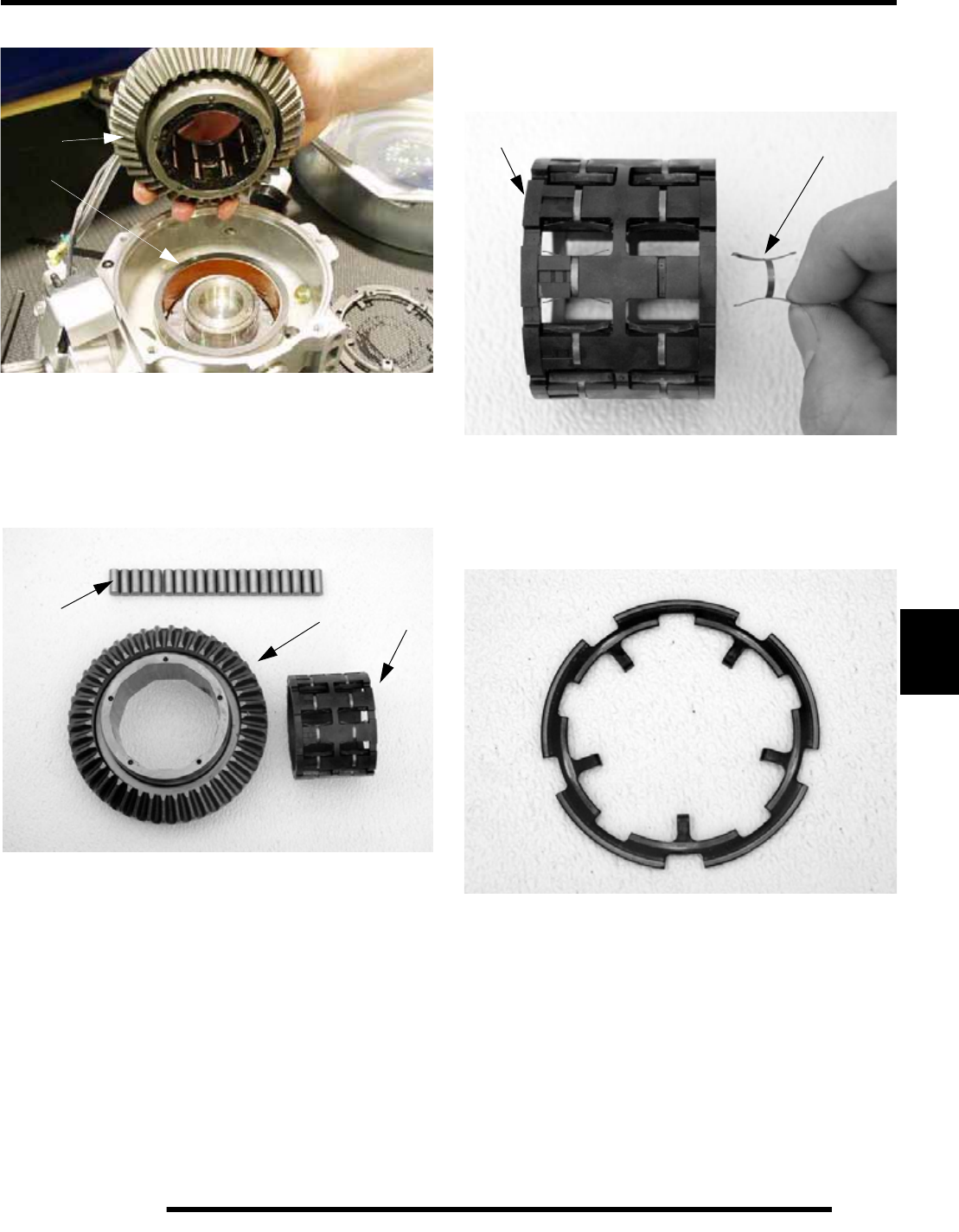

8. Remove the ring gear (1) and spacer (2).

9. Remove and inspect the bearing surfaces of the output hub.

10. Thoroughly clean all parts.

11. Inspect the rollers (1) for nicks, scratches and flat spots.

Inspect the roll cage (2) for damage or cracks. The rollers

must slide up and down freely within the roller cage

surfaces. Inspect the ring gear (3) for consistent wear

patterns. Surfaces should be free of nicks or burrs.

12. Inspect roll cage sliding surface (2). This surface must be

clean and free of nicks, burrs or scratches. Remove and

inspect the H-springs (4). Replace any components as

required.

13. Inspect the armature plate for a consistent wear pattern.

Uneven wear of the armature plate indicates a warped

plate, which may cause intermittent operation.

NOTE: See “Front Gearcase Diagnosis” on

page 7.19.

1

2

3

2

1

2

4