2.29

MAINTENANCE

2

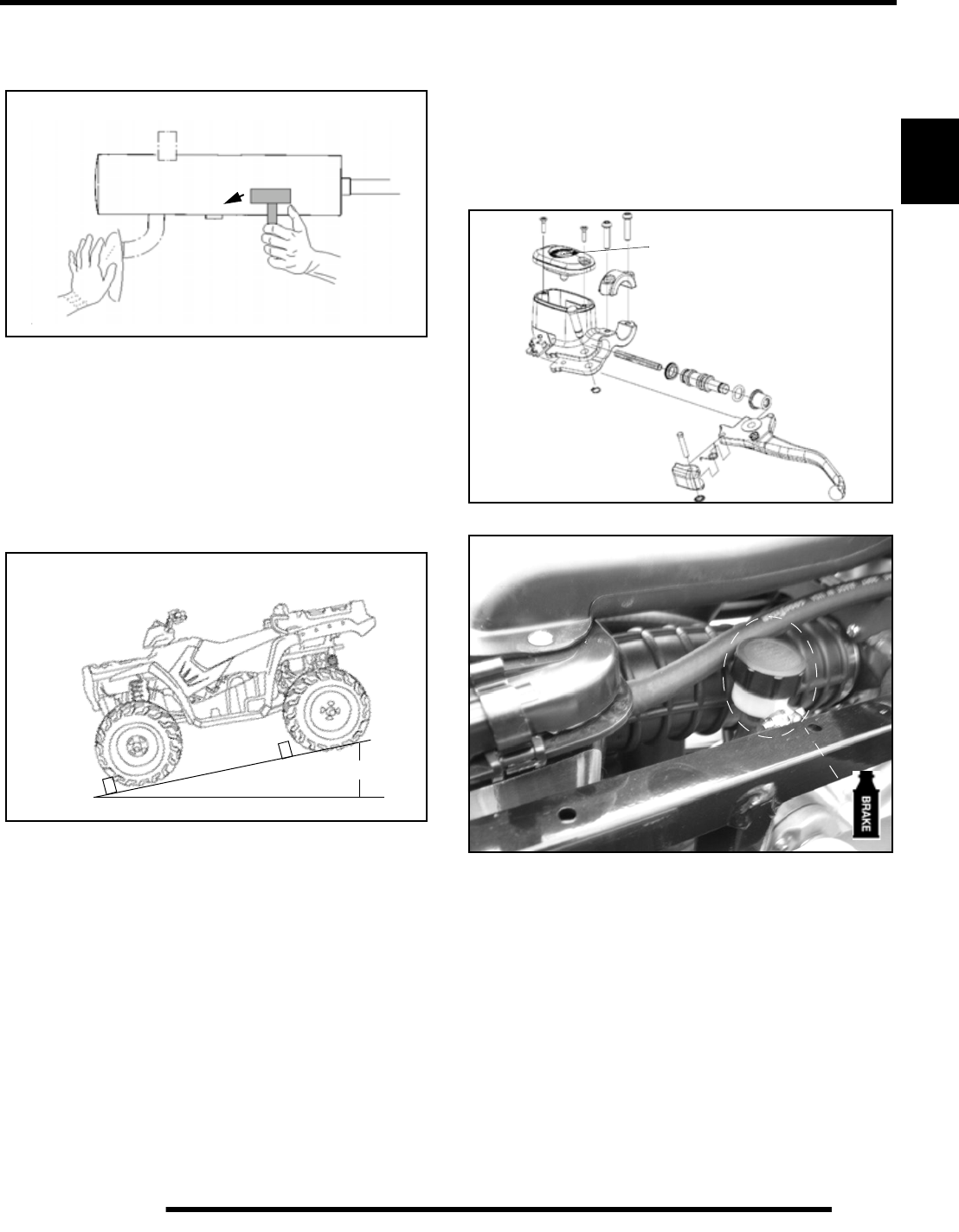

3. If some carbon is expelled, cover the exhaust outlet and

lightly tap on the pipe around the clean out plugs with a

rubber mallet while revving the engine several more times.

4. If particles are still suspected to be in the muffler, back the

machine onto an incline so the rear of the machine is one

foot higher than the front. Set the hand brake and block the

wheels. Make sure the machine is in Park and repeat Steps

2 and 3. SEE WARNING

5. If particles are still suspected to be in the muffler, drive the

machine onto the incline so the front of the machine is one

foot higher than the rear. Set the hand brake and block the

wheels. Make sure the machine is in Park and repeat Steps

2 and 3. SEE WARNING

6. Repeat steps 2 through 5 until no more particles are

expelled when the engine is revved.

7. Stop the engine and allow the arrestor to cool.

8. Reinstall the clean out plugs.

Brake System Inspection

The following checks are recommended to keep the brake

system in good operating condition. Service life of brake system

components depends on operating conditions. Inspect brakes in

accordance with the maintenance schedule and before each ride.

• Keep fluid level in the master cylinder reservoir to the

indicated level inside reservoir.

• Use Polaris DOT 3 Brake Fluid

• Use Polaris DOT 3 Brake Fluid

• Check brake for excessive travel or spongy feel.

• Check brake system for fluid leaks.

• Check friction pads for wear, damage or looseness.

• Check surface condition of the disc.

1 ft.

Sight Glass

Parking Lock Brake