4.18

FUEL INJECTION

3. Disconnect crankshaft sensor connector from wiring

harness. Test resistance between the terminals. A reading

of 185

20% at room temperature (20C, 68 F)

should again be obtained.

NOTE: If the resistance reading is incorrect, remove

the screws securing the sensor to the mounting

bracket and replace the sensor. If the resistance in

step 2 was incorrect, but the resistance of the

sensor alone was correct, test the main harness

circuit between the sensor connector terminals and

the corresponding pin terminals in the main

connector. Correct any observed problem,

reconnect the sensor, and perform step 2 again.

Crankshaft Position Sensor Replacement

1. Remove the RH footwell and rear body panel to gain

access to the recoil cover.

2. Disconnect sensor harness connector.

3. Using an 8 mm socket, remove the recoil cover retaining

bolts. A mallet or soft hammer may be required to loosen

the cover for removal.

4. Remove the retainer screws securing the sensor.

5. Install the new sensor, routing the harness wire through the

top of the case housing as was previously installed.

6. Set the air gap of the new sensor to the specified distance

away from the ring gear. Torque the retaining screws to

specification and reverify air gap.

MANIFOLD AIR PRESSURE SENSOR

(MAP)

Operation Overview

Mounted on the throttle body intake, the manifold air pressure

sensor (MAP) measures air passing and provides the ECM with

the manifold pressure during engine operation. This allows the

ECM to adjust the fueling according to actual engine load as

well as identify which stroke is the intake stroke. The MAP

sensor also provides the ECM with the ability to compensate for

high altitude operation without any recalibration.

During initial start-up, the ECM is in a “waste spark - waste

fuel” mode until the MAP sensor sends a negative pressure

reading, indicating that the engine is on the intake stroke. Once

this has been ‘learned’, the ECM will then monitor the MAP

sensor and cease the initial start-up program.

Map Sensor Test

MAP sensors are a non-serviceable item. If it is faulty, it must

be replaced. This sensor requires a 5 Vdc input to operate,

therefore the MAP sensor should only be tested using Polaris

Diagnostic Software (dealer only). Refer to the EFI Diagnostic

Software Manual for more information.

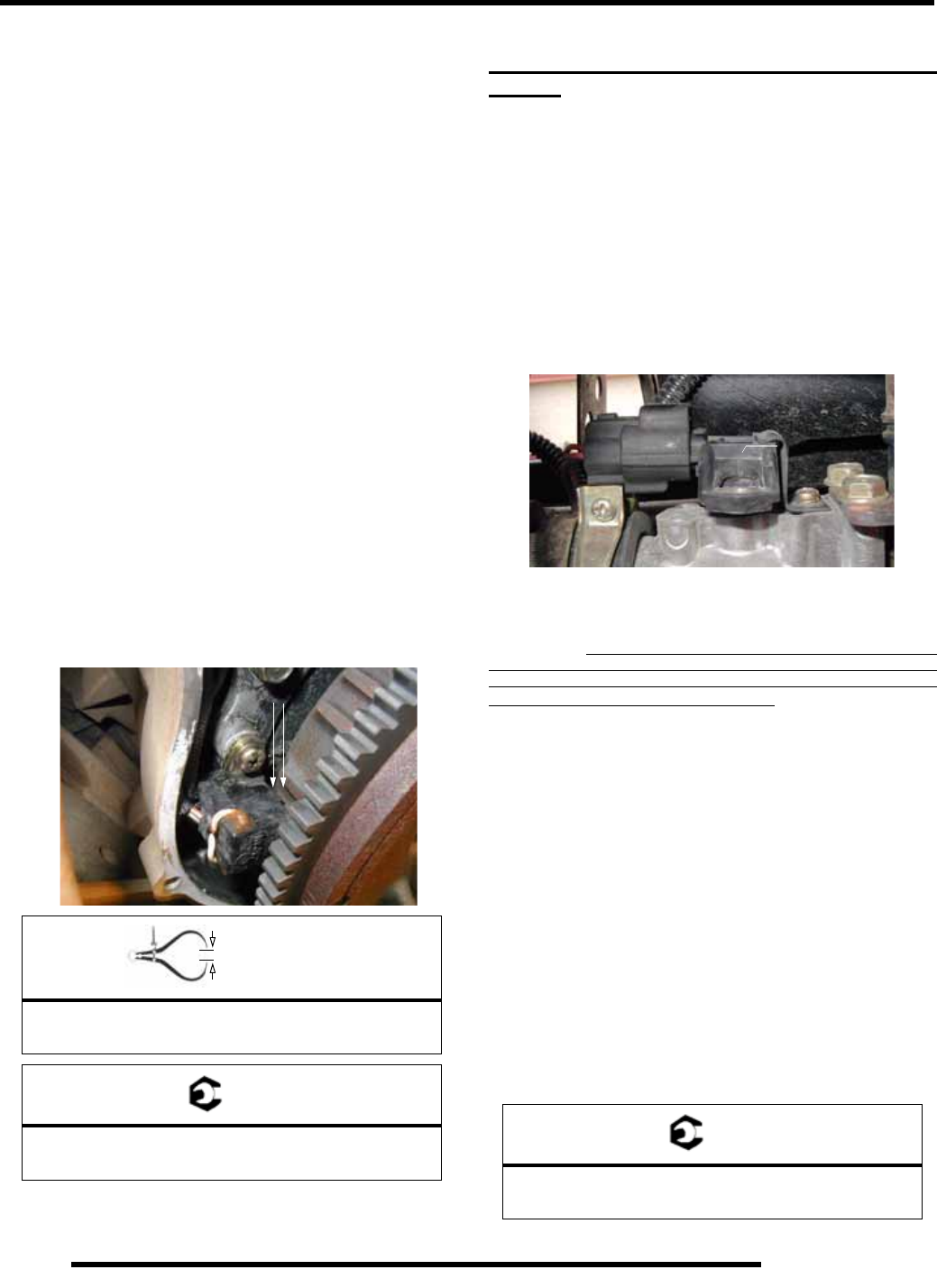

Map Sensor Replacement

1. Disconnect sensor from engine harness.

2. Using a suitable tool, remove the retaining screw and

replace the sensor, using a light coating of soapy water on

the grommet to aid installation.

NOTE: Replacement MAP sensors may have an o-

ring installed that must be removed prior to

installing the grommet.

3. Install the sensor as shown in Figure 1, inserting it with a

twisting motion to properly seat the grommet. Verify that

the connector centerline is aligned with the throttle body

centerline.

4. Install the retaining bracket. NOTE: Do not allow the

retaining bracket to contact the MAP body. Torque the

retaining screw to specification.

= In. / mm.

CPS Air Gap:

0.4 - 1.2 mm (0.015 - .047 in.)

= T

CPS Retaining Screws:

26-34 in. lbs. (2.9-3.92 Nm)

0.4 - 1.2 mm (0.015 -

.047 in.)

= T

MAP Retaining Screw:

29 in. lbs. (3.3 Nm)

Do not allow bracket to contact MAP