2-9

Installation

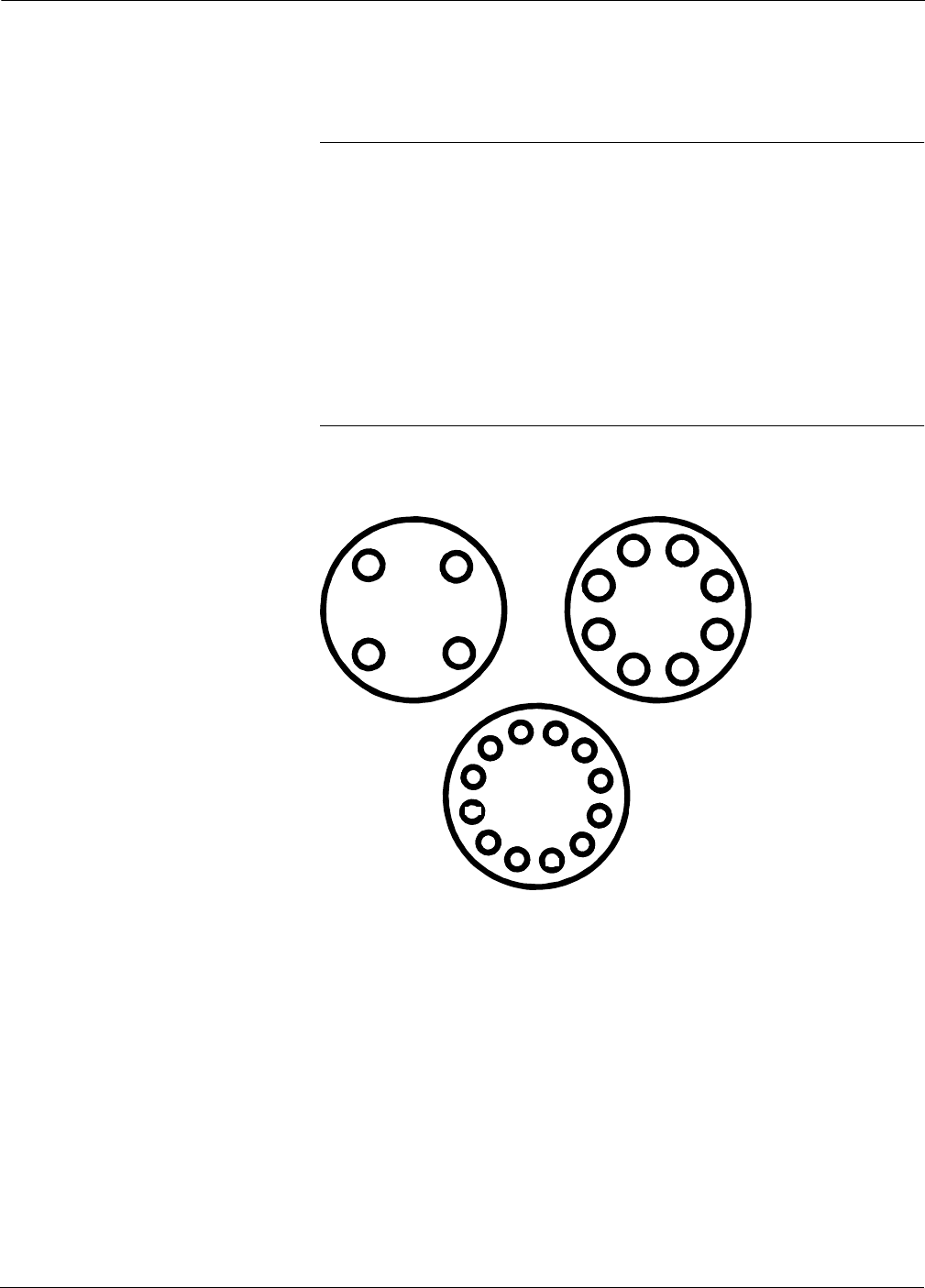

Flanged-Style

Flowmeter Mounting

Mounting a flanged-style flowmeter is similar to installing a typical

section of pipe. Conventional tools, equipment, and accessories (such as

bolts and gaskets) are required. Tighten the nuts following the

sequence shown in Figure 2-8.

NOTES

The required bolt load for sealing the gasket joint is affected by several

factors, including operating pressure and gasket material, width, and

condition. A number of factors also affect the actual bolt load resulting

from a measured torque, including condition of bolt threads, friction

between the nut head and the flange, and parallelism of the flanges.

Due to these application-dependent factors, the required torque for each

application may be different. Follow the guidelines outlined in the

ASME Pressure Vessel Code (Section VIII, Division 2) for proper

bolt tightening.

Make sure the flowmeter is centered between flanges of the same

nominal size as the flowmeter.

Figure 2-8. Flange Bolt

Torquing Sequence.

Flowmeter Grounding Grounding is not required in typical vortex applications; however, a

good ground will eliminate possible noise pickup by the electronics.

Grounding straps may be used to ensure that the meter is grounded to

the process piping.

To use grounding straps, secure one end of the grounding strap to the

bolt extending from the side of the meter body and attach the other end

of each grounding strap to a suitable ground.

Electronics Considerations Integral and remote-mounted electronics require input power at the

electronics. For remote-mount installations, mount the electronics

against a flat surface or on a pipe that is up to two inches in diameter.

Pipe and surface-mounting hardware is included with remote-mount

electronics. See Figure 2-16 on page 2-18 for dimensional information.

1

3

2

4

1

5

3

7

2

6

4

8

1

5

9

3

7

11

2

6

10

4

8

12

8800-0088A

4-Bolt

12-Bolt

8-Bolt