Rosemount Model 8800C Vortex Flowmeter with FOUNDATION

™

Fieldbus

2-2

Flowmeter Orientation Design process piping so the meter body will remain full, with no

entrapped air. Allow enough straight pipe both upstream and

downstream of the meter body to ensure a nonskewed, symmetrical

profile. Install valves downstream of the meter when possible.

Vertical Installation Vertical installation allows upward process liquid flow and is generally

preferred. Upward flow ensures that the meter body always remains

full and that any solids in the fluid are evenly distributed.

The vortex meter can be mounted in the vertical down position when

measuring gas or steam flows. This type of application should be

strongly discouraged for liquid flows, although it can be done with

proper piping design.

NOTE

To ensure that the meter body remains full, avoid downward vertical

liquid flows where back pressure is inadequate.

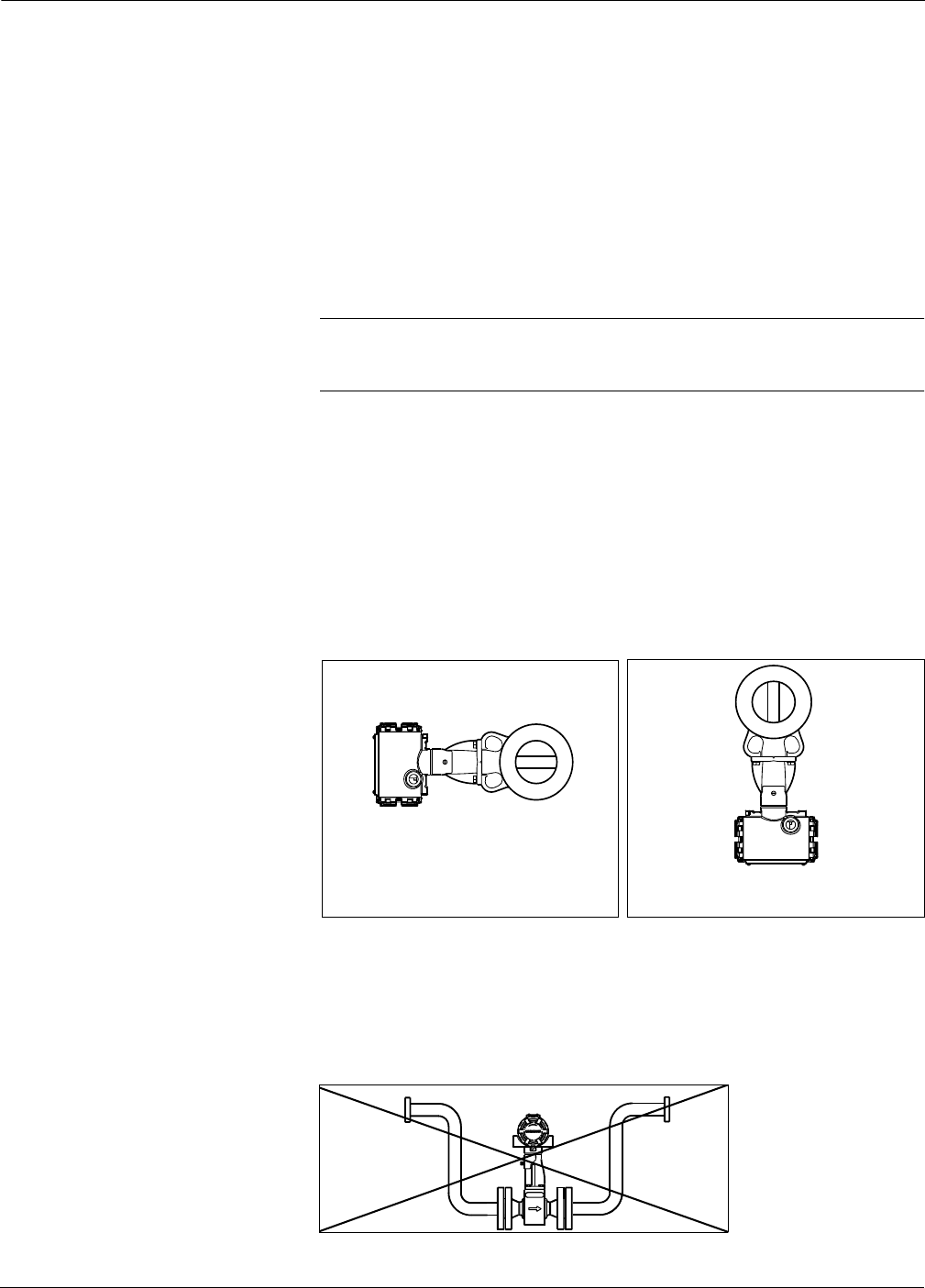

High-Temperature Installations Install the meter body so the electronics are positioned to the side of

the pipe or below the pipe, as shown in Figure 2-1. Insulation may be

required around the pipe to maintain a temperature below 185 °F

(85 °C).

When insulating, the insulation should be made only around the pipe

and meter body. Leave part of the support tube bracket exposed to

ambient environment for both remote and integral installations. This

aids in dissipating the heat from the process.

Figure 2-1.

Examples of High-Temperature

Installations.

Steam Installations For steam applications, avoid installations such as the one shown in

Figure 2-2. Such installations may cause a water-hammer condition at

start-up due to trapped condensate. The high force from the water

hammer can overstress the sensing mechanism and cause permanent

damage to the sensor.

Figure 2-2.

Avoid This Type of Installation for

Steam Applications.

The meter body installed with the

electronics to the side of the pipe.

The meter body installed with the

electronics below the pipe.

8800-0002A01C8800-8800G15