– 14 –

INSP

ADJ

INTRODUCTION/

PERIODIC MAINTENANCE/LUBRICATION

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjust-

ments. These preventive maintenance procedures, if followed, will ensure more reliable machine

operation and a longer service life. In addition, the need for costly overhaul work will be greatly

reduced. This information applies to machines already in service as well as new machines that are

being prepared for sale. All service technicians should be familiar with this entire chapter.

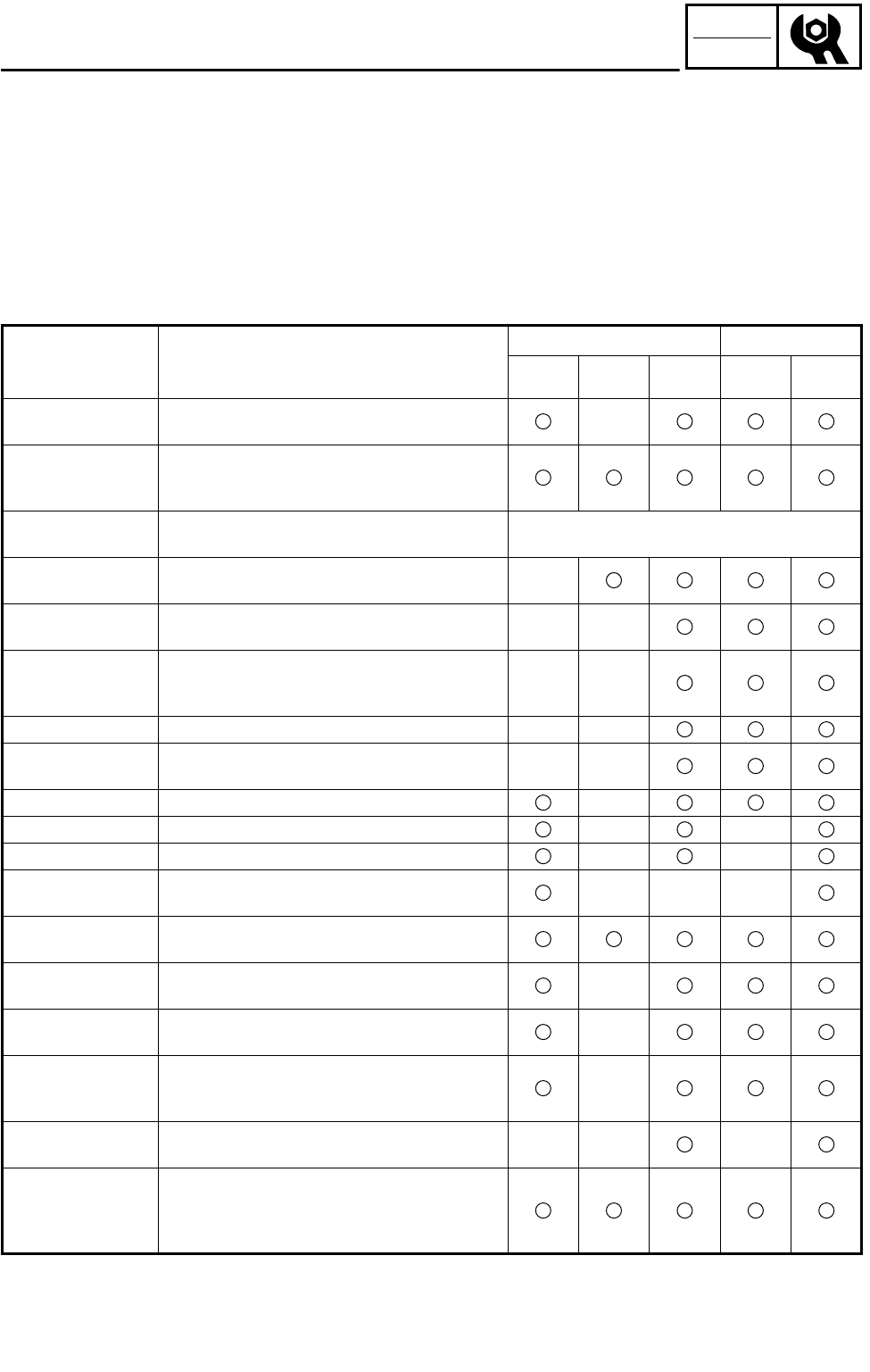

PERIODIC MAINTENANCE/LUBRICATION

ITEM ROUTINE

INITIAL EVERY

1

month

3

months

6

months

6

months

1

year

Valves*

• Check valve clearance.

• Adjust if necessary.

Spark plug

• Check condition.

• Adjust gap and clean.

• Replace if necessary.

Air filter

• Clean.

• Replace if necessary.

Every 20 ~ 40 hours

(more often in wet or dusty areas.)

Carburetor*

• Check idle speed/starter operation.

• Adjust if necessary.

Cylinder head

breather system*

• Check breather hose for cracks or damage.

• Replace if necessary.

Exhaust system*

• Check for leakage.

• Retighten if necessary.

• Replace gasket if necessary.

Spark arrester • Clean.

Fuel line*

• Check fuel hose for cracks or damage.

• Replace if necessary.

Engine oil • Replace (Warm engine before draining).

Engine oil filter • Clean.

Engine oil strainer • Clean.

Final gear oil

• Check oil level/oil leakage.

• Replace.

Brakes*

• Check operation.

• Adjust if necessary.

Clutch*

• Check operation.

• Adjust if necessary.

Wheels*

• Check balance/damage/runout.

• Replace if necessary.

Wheel bearings*

• Check bearing assembly for looseness/dam-

age.

• Replace if damaged.

Front and rear sus-

pension*

• Check operation.

• Correct if necessary.

Steering system*

• Check operation.

• Correct if necessary.

• Check toe-in.

• Adjust if necessary.