4 - 43

ENG

INSPECTION AND REPAIR

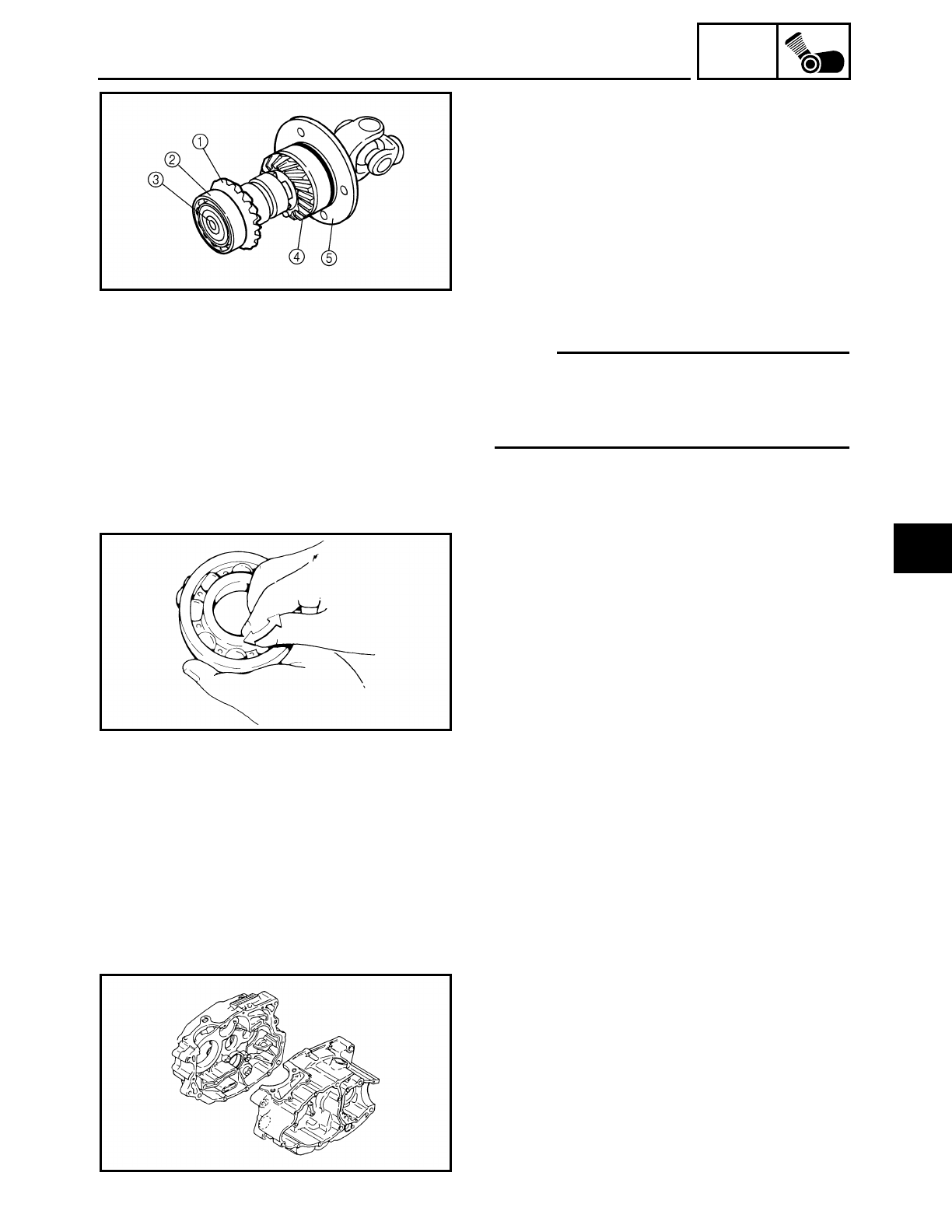

MIDDLE GEAR

1.Inspect:

● Middle driven pinion gear 1

● Bearing 2

● Middle driven shaft 3

● Reverse gear 4

● Bearing housing 5

Damage/Wear → Replace.

2.Check:

● Bearing movement

Turns roughly → Replace.

NOTE:

When the driven pinion gear, reverse gear,

middle driven shaft and/or bearing housing

are replaced, be sure to adjust the middle

gear shim(s).

Refer to the “DRIVE TRAIN-MIDDLE GEAR

SERVICE” section in CHAPTER 6.

BEARINGS AND OIL SEALS

1.Inspect:

● Bearings

Pitting/Damage → Replace.

2.Inspect:

● Oil seals

Damage/Wear → Replace.

CIRCLIPS AND WASHERS

1.Inspect:

● Circlips

● Washers

Damage/Looseness/Bends → Replace.

CRANKCASE

1.Thoroughly wash the case halves in mild

solvent.

2.Clean all the gasket mating surfaces and

crankcase mating surfaces thoroughly.

4