4 - 33

ENG

INSPECTION AND REPAIR

2nd steps

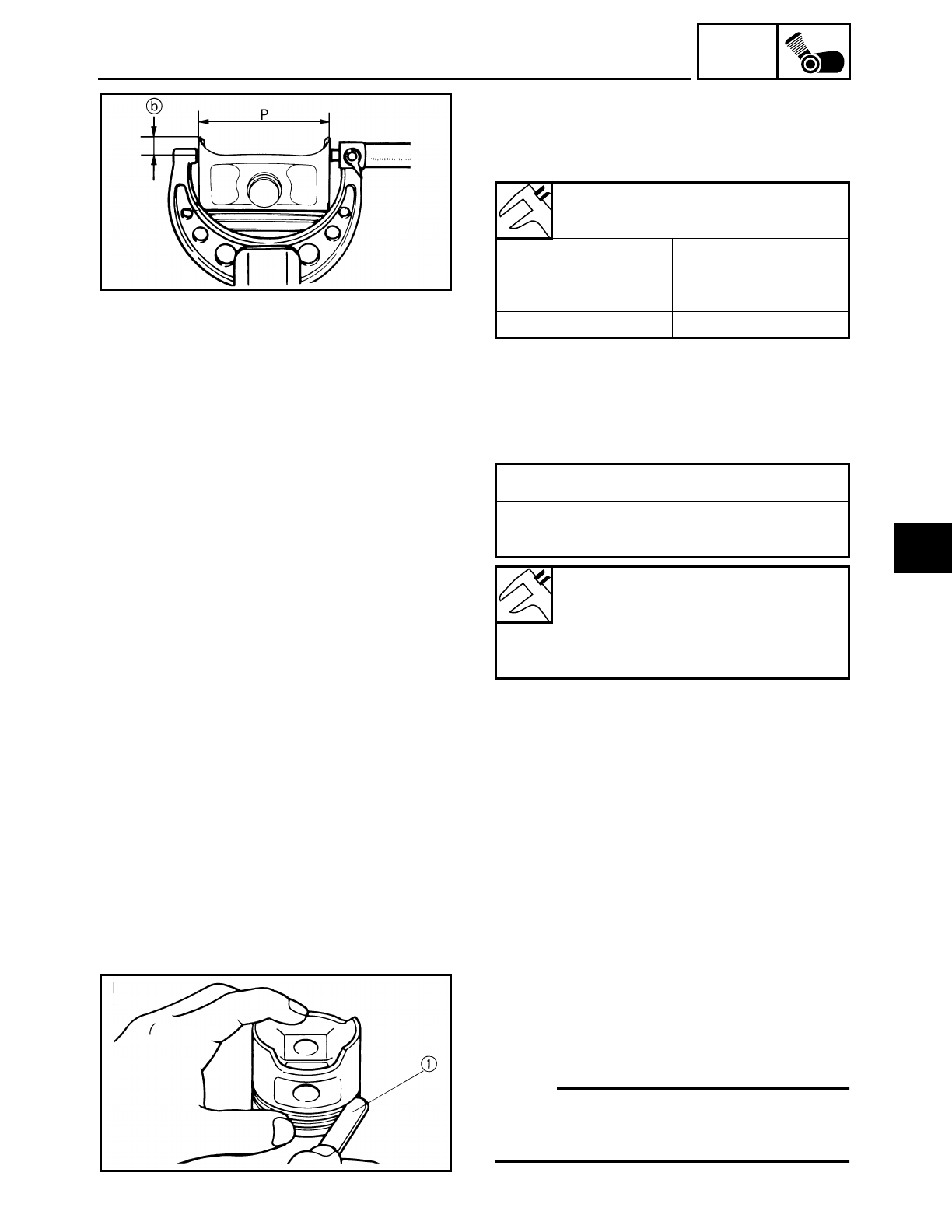

●Measure the piston skirt diameter “P”

with a micrometer.

b 4 mm (0.16 in) from the piston bottom edge

●If out of the specification, replace the pis-

ton and piston rings as a set.

3rd steps

●Find the piston-to-cylinder clearance with

following formula.

●If out of the specification, rebore or

replace the cylinder, and replace the pis-

ton and piston rings as a set.

*********************************

PISTON RING AND PISTON PIN

Piston ring

1.Measure:

● Side clearance

Use the Feeler Gauge 1.

Out of specification → Replace piston and/

or rings as a set.

NOTE:

Eliminate carbon deposits from the piston

ring grooves and rings before measuring

the side clearance.

Piston skirt Diameter “P”

Standard

70.92 ~ 70.97 mm

(2.792 ~ 2.794 in)

Oversize 2 71.50 mm (2.815 in)

Oversize 4 72.00 mm (2.846 in)

Piston-to-cylinder clearance =

Cylinder bore “C” –

Piston skirt diameter “P”

Piston-to-cylinder clearance:

0.04 ~ 0.06 mm

(0.0016 ~ 0.0024 in)

< Limit >:

0.15 mm (0.0059 in)

4