If the driveshaft tube requires straightening or

replacement, balance the repaired driveshaft be-

fore installing it. See Group 41 of the

Acterra

®

Workshop Manual

.

7. Check the driveshaft for missing balance

weights, and for debris build-up. Remove any

build-up. If any balance weights are missing, re-

move the driveshaft and have it balanced; see

Group 41 of the

Acterra

®

Workshop Manual

.

8. For driveshafts with slip-joints, check that the

yoke plug is not loose or missing. See Fig. 4,

Ref. 2. Replace the yoke plug if needed. If the

yoke plug is missing, the splined shaft may be

hitting the yoke plug and knocking it out; check

the driveshaft for proper length.

41–02 Driveline Lubricating

U-Joint Lubricating

1. Wipe all old grease and dirt from each U-joint

grease fitting. See Fig. 4, Ref. 8.

2. Use a hand-type grease gun, or a high-pressure

gun with a low-pressure adapter, to lubricate the

U-joints.

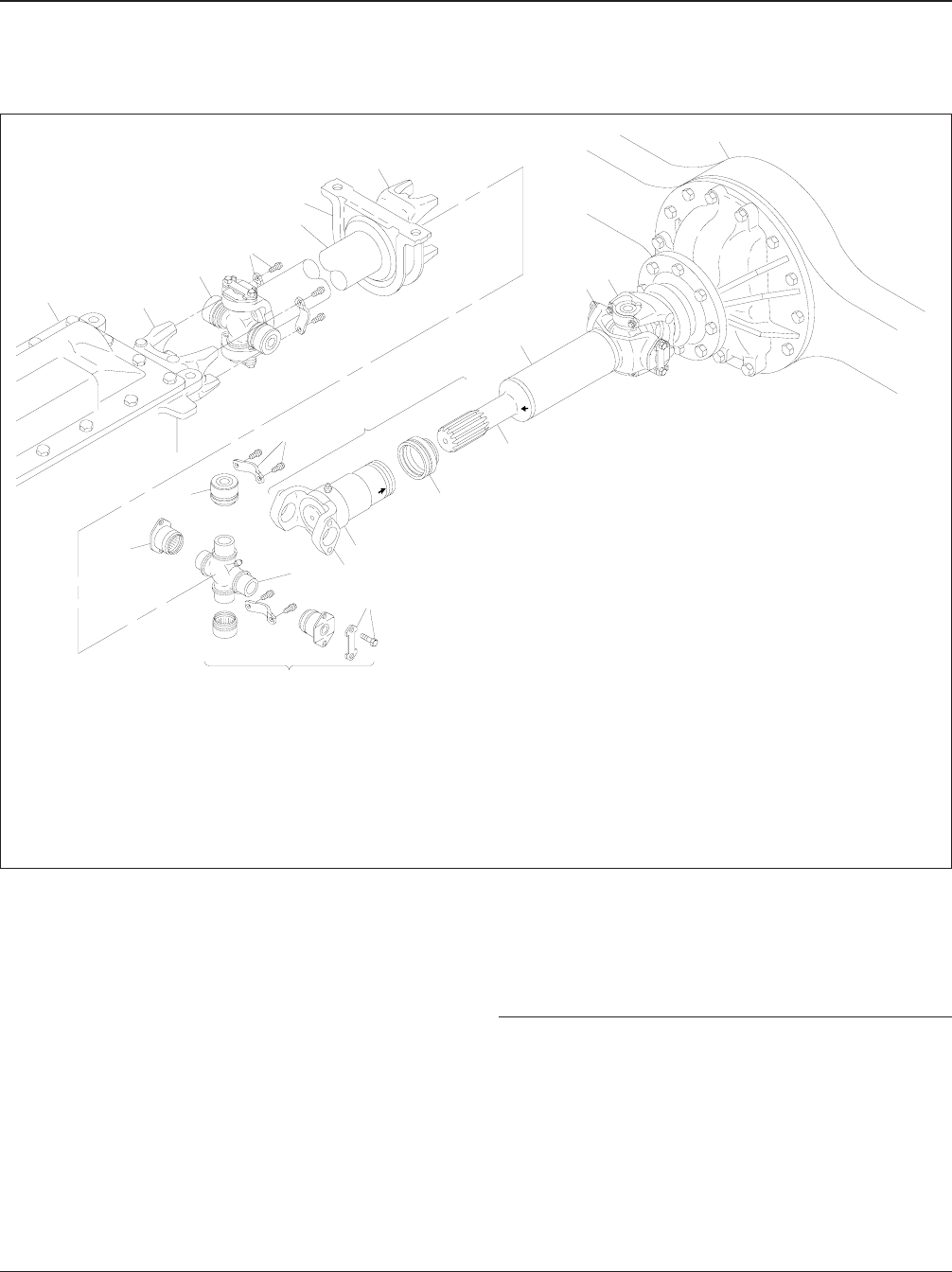

f410057a

10/06/94

1

2

3

5

6

4

2

4

7

16

15

14

13

18

17

9

8

3

7

10

11

12

NOTE: Not all fasteners are shown.

1. Transmission

2. Half-Round End Yoke

3. U-Joint Assembly

4. Yoke Strap and Capscrew

5. Coupling Shaft

6. Midship Bearing and Mount

7. Bearing Cup

8. Slip-Joint Assembly

9. Driveshaft Tube

10. Driveshaft Yoke

11. Input Shaft Half-Round End

Yoke

12. Rear Axle

13. Splined Shaft

14. Dust Seal

15. Sleeve Yoke

16. Full-Round-Yoke Lug

17. U-Joint Cross

18. Lockplate and Capscrew

Fig. 1, Driveline Assembly With Midship Bearing for Single-Axle Installation

Driveline41

Acterra Maintenance Manual, March 200041/2