11. Check and adjust the fluid level using the proce-

dure under "Checking the Fluid Level."

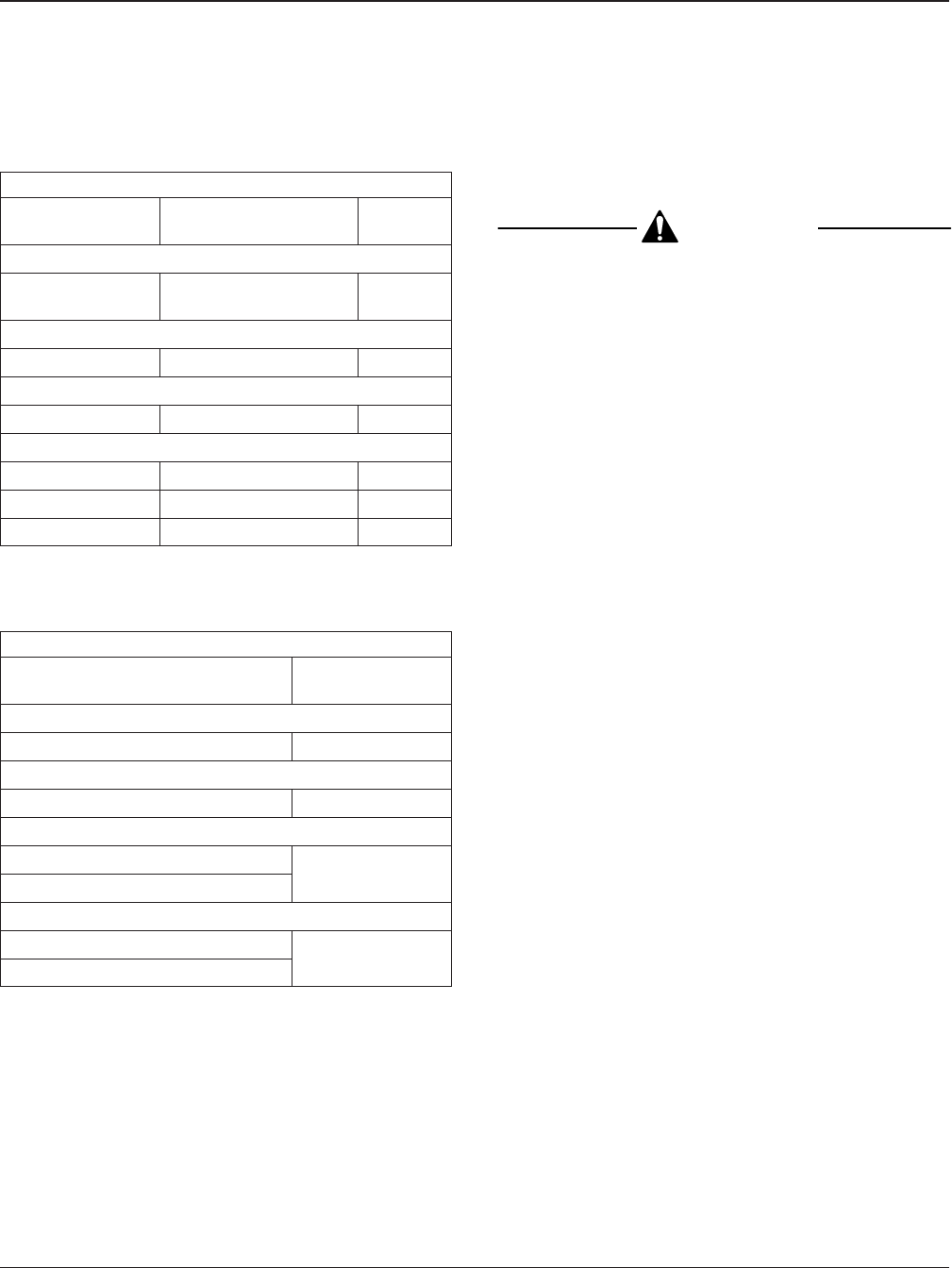

Approved Allison Transmission Lubricants

Lubricant Type

*

Temperature: °F (°C)

SAE

Viscosity

All Allison Transmissions

Castrol TranSynd

™

(synthetic)

Above –22 (–30) —

On-Highway Transmissions (1000/2000/2400 Series)

Dexron

®

III Above –13 (–25) —

AT and MD Series

Dexron III Above –13 (–25) —

MT Series

Dexron III Above –13 (–25) —

Type C4 10 to 120 (–12 to 48) SAE 10W

Type C4 32 to 120 (0 to 48) SAE 30W

*

Lubricants listed in order of preference. Do not mix types of oil.

Table 3, Approved Allison Transmission Lubricants

Allison Transmission Lubricant Capacities

Transmission Model

Fill Capacity

*

:

quarts (liters)

On-Highway Series

1000/2000/2400 15.0 (14.2)

AT Series

AT–545 16.0 (15.1)

MT Series

MT–643

15.0 (14.2)

MT–653

MD Series

MD–3060

19.0 (18.0)

MD–3560

*

Quantities listed are approximate. Add the recommended amount of fluid

as listed under fill capacity, then perform a "hot check" and add fluid as

needed. Do not overfill.

Table 4, Allison Transmission Lubricant Capacities

AT Series

1. Park the vehicle on a level surface and apply the

parking brakes.

2. Run the engine until the transmission fluid

reaches the operating temperature of 160 to

200°F (71 to 93° C). Shift the transmission to

neutral (N) and shut down the engine.

CAUTION

To prevent dirt from entering the transmission,

use only clean containers and fillers for the trans-

mission fluid. Do not use fillers or containers that

have been used for water or antifreeze. Dirt, water,

or antifreeze could damage the transmission.

3. Clean the area around the drain plug. While the

transmission fluid is warm, remove the drain plug

and drain the fluid. Disconnect the fill tube from

the oil pan.

IMPORTANT: Examine the used transmission

fluid for dirt, coolant or water, and metal par-

ticles. If any of these contaminants are present,

a problem may exist within the transmission

system.

4. Support the oil pan, then remove the twenty-one

washer-head screws that attach the oil pan to

the transmission case. Remove the pan, and dis-

card the pan gasket.

5. Clean the oil pan with mineral spirits.

6. Remove the washer-head screw that attaches

the internal fluid filter to the filter spacer, then

remove the filter and discard it. See Fig. 3. Re-

move the fluid intake tube, then remove the seal

ring from the intake tube, and discard the seal

ring.

7. Remove, clean, and install the governor feed line

screen, located in the control valve body. See

Fig. 4.

8. Install a new seal ring in the fluid intake tube.

IMPORTANT: Avoid twisting the intake tube

when installing the internal fluid filter, intake

tube, and seal ring; the seal ring could be

pinched, cut, or deformed. An air-tight seal must

be maintained.

9. Install the intake tube, with the seal ring installed,

into the main housing. Install the internal fluid

filter on the intake tube, making sure the grom-

met in the filter fits the intake tube snugly.

10. Install the washer-head screw to retain the fluid

filter, and tighten it 10 to 15 lbf·ft (14 to 20 N·m).

Transmission26

Acterra Maintenance Manual, March 200526/4