3. Clean any road grime from the relay valve and

any debris from the valve exhaust port.

4. Listen for air leakage around the fittings or ex-

haust port. Tighten the fittings as necessary. Use

two wrenches to avoid twisting the tubing.

5. If the valve fails this check or is damaged, repair

or replace it. For instructions, see the Midland

service manual.

6. Remove the chocks from the tires.

42–06 Quick Release and

Flipper Valves Checking,

Midland

1. Park the vehicle on a level surface. Chock the

tires.

2. Start the engine and run it long enough to pres-

surize the air system to at least 80 psi (550 kPa).

Turn off the engine. Repeat as necessary to

maintain 80 psi (550 kPa) pressure during these

checks.

3. Clean any road grime from the valves and any

material from the valves’ exhaust ports.

4. Listen for air leakage around the fittings and ex-

haust ports. Tighten the fittings as necessary.

Use two wrenches to avoid twisting the tubing.

5. If any valve fails this check or is damaged, repair

or replace it. For instructions, see the Midland

service manual.

6. Remove the chocks from the tires.

42–07 Brake Chamber

Inspecting (All Models)

WARNING

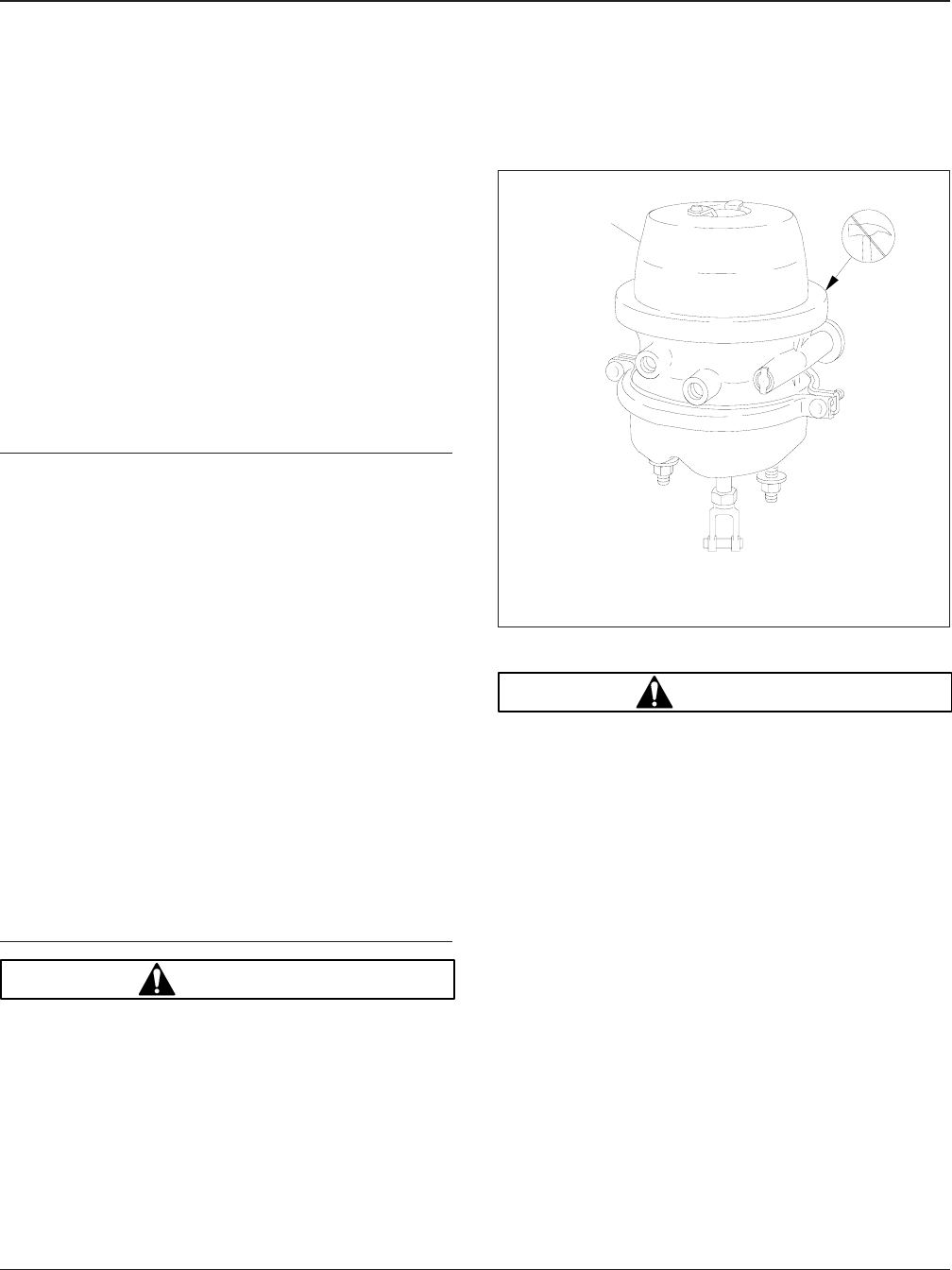

Do not loosen or remove the parking brake clamp

ring for any purpose at any time. See Fig. 1. The

parking/emergency brake section is not intended

to be serviced. Serious injury or death may result

from sudden release of the power spring.

Before doing any repairs or adjustments on a

service/parking brake chamber, read the appli-

cable warnings and instructions in the applicable

brake chamber section in Group 42 of the

Acterra

®

Workshop Manual

.

WARNING

Do not operate the vehicle with the front brakes

backed off or disconnected. Backing off or discon-

necting the front brakes will not improve vehicle

handling and may lead to loss of vehicle control

resulting in property damage or personal injury.

NOTE: Vehicles operating under severe or ad-

verse conditions should be checked more fre-

quently. If the brake chamber requires disas-

sembly, see Group 42 of the

Acterra

®

Workshop Manual

for instructions.

1. With the slack adjuster properly adjusted, check

the angle formed by the centerline of the piston

rod and slack adjuster. This angle should be

greater than 90 degrees in the released position

and approach 90 degrees in the applied position.

See Fig. 2.

At angles less than 90 degrees, brake chamber

force is reduced, which reduces braking

efficiency.

1

A

02/22/2000

f421352

A. Do not remove the factory-sealed clamp ring.

1. Model TR-T (TR Series) Brake Chamber

Fig. 1, MGM Brake Chamber

Brakes42

Acterra Maintenance Manual, October 200742/2