vented from contacting areas of the oil pan

flange that are inside the raised bead of the

flange.

NOTE: Do not use gasket-type sealing com-

pounds or cement anywhere inside the trans-

mission or where they might get washed into

the transmission. Non-soluble vegetable-base

cooking compounds or fibrous grease must not

be used inside the transmission.

12. Install the oil pan and gasket onto the transmis-

sion. Check that no dirt or debris enters the pan.

Secure the pan to the transmission housing with

four 5/16–18 washer-head capscrews, installed

into the corners of the oil pan, but do not tighten.

13. Install the remaining 17 washer-head capscrews

by hand. Check that all of the capscrews are

hand-tight.

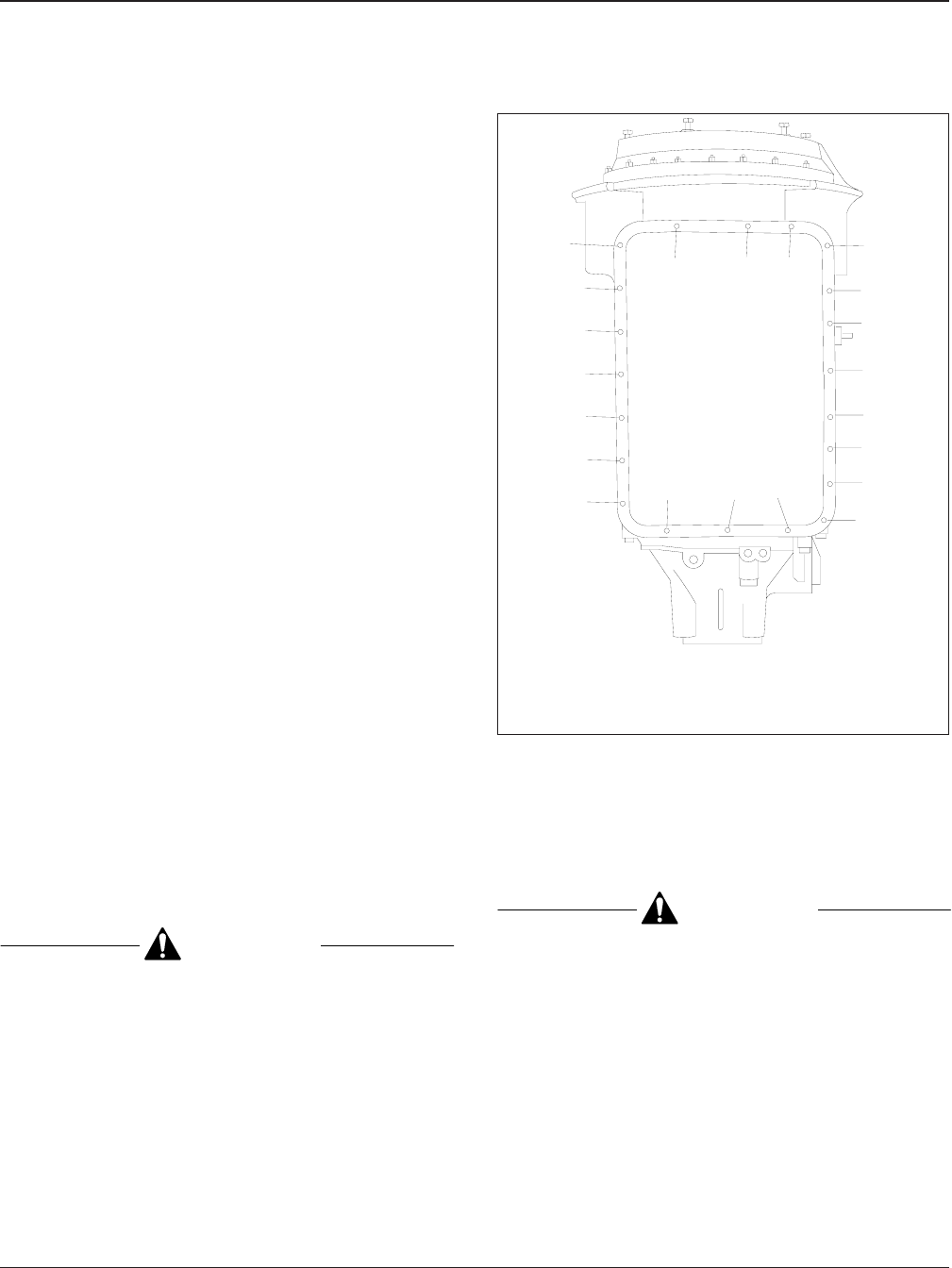

14. Using a click-type torque wrench, tighten each

capscrew 5 lbf·ft (7 N·m). See Fig. 7 for the pat-

tern needed to distribute the torque evenly.

When all the capscrews are tightened to the first

stage, repeat this procedure. This time, torque all

the capscrews 15 to 20 lbf·ft (20 to 27 N·m).

15. Install the oil filler tube on the oil pan. Tighten

the tube fitting 90 to 100 lbf·ft (122 to 136 N·m),

then install the drain plug and gasket. Tighten

the drain plug 15 to 20 lbf·ft (20 to 27 N·m).

16. Pour approximately 15 quarts (14 liters) of trans-

mission fluid into the transmission. Start the en-

gine and allow the transmission fluid to circulate.

With the transmission in NEUTRAL, check the

fluid level. Check for fluid leaks. Correct any leak

with the engine OFF.

Checking the Fluid Level

CAUTION

Operating a transmission with the fluid level

higher or lower than recommended can result in

transmission damage. Do not overfill the transmis-

sion.

Do not mix types and brands of fluid, because of

possible incompatibility. Do not use fluid addi-

tives, friction modifiers, extreme-pressure gear

fluids, or multiviscosity lubricants.

Cold Check

Clean all dirt away from around the end of the fluid

fill tube before removing the dipstick.

CAUTION

Do not allow foreign matter to enter the transmis-

sion. Dirt or foreign matter in the hydraulic system

may cause undue wear of transmission parts,

make valves stick, and clog passages.

It is important to check the fluid level cold to deter-

mine if the transmission has a sufficient amount of

fluid to be safely operated until a hot check can be

performed.

1. Park the vehicle on a flat, level surface.

2. Apply the parking brakes and chock the rear

tires.

09/24/96

f260396

1

13

17

19

15

11

3

5

9

7

6108

4

12

16

20

21

18

14

2

NOTE: Torque the oil pan bolts with a click-type torque

wrench following this torque pattern. Tighten the bolts 5

lbf·ft (7 N·m), then repeat the torque pattern with a click-

type torque wrench 15 to 20 lbf·ft (20 to 27 N·m).

Fig. 7, Allison MT Series Transmission, Oil Pan Torque

Pattern

Transmission 26

Acterra Maintenance Manual, March 2005 26/9