42–08 Camshaft Bracket

Bushing Lubricating

IMPORTANT: Perform MOP 42–24 before lubri-

cating the camshaft brackets.

Pump multipurpose chassis grease (NLGI Grade 1 or

2) into the chamber bracket until it appears at the

slack adjuster end of the bracket. See Fig. 4. Use

care that no grease enters the drum cavity. If grease

leaks out under the camhead, the camshaft grease

seal is worn or damaged, or is installed backwards.

NOTE: The use of meter-type fittings, having a

maximum 40 psi (275 kPa) pressure relief at

shutoff, is recommended.

42–09 Automatic Slack

Adjuster Checking,

Meritor

WARNING

Manually adjusting an automatic slack adjuster to

bring the pushrod stroke within legal limits is

likely masking a mechanical problem. Adjustment

is not repairing. Before adjusting an automatic

slack adjuster, troubleshoot the foundation brake

system and inspect it for worn or damaged com-

ponents. Improperly maintaining the vehicle brak-

ing system may lead to brake failure, resulting in

property damage, personal injury, or death.

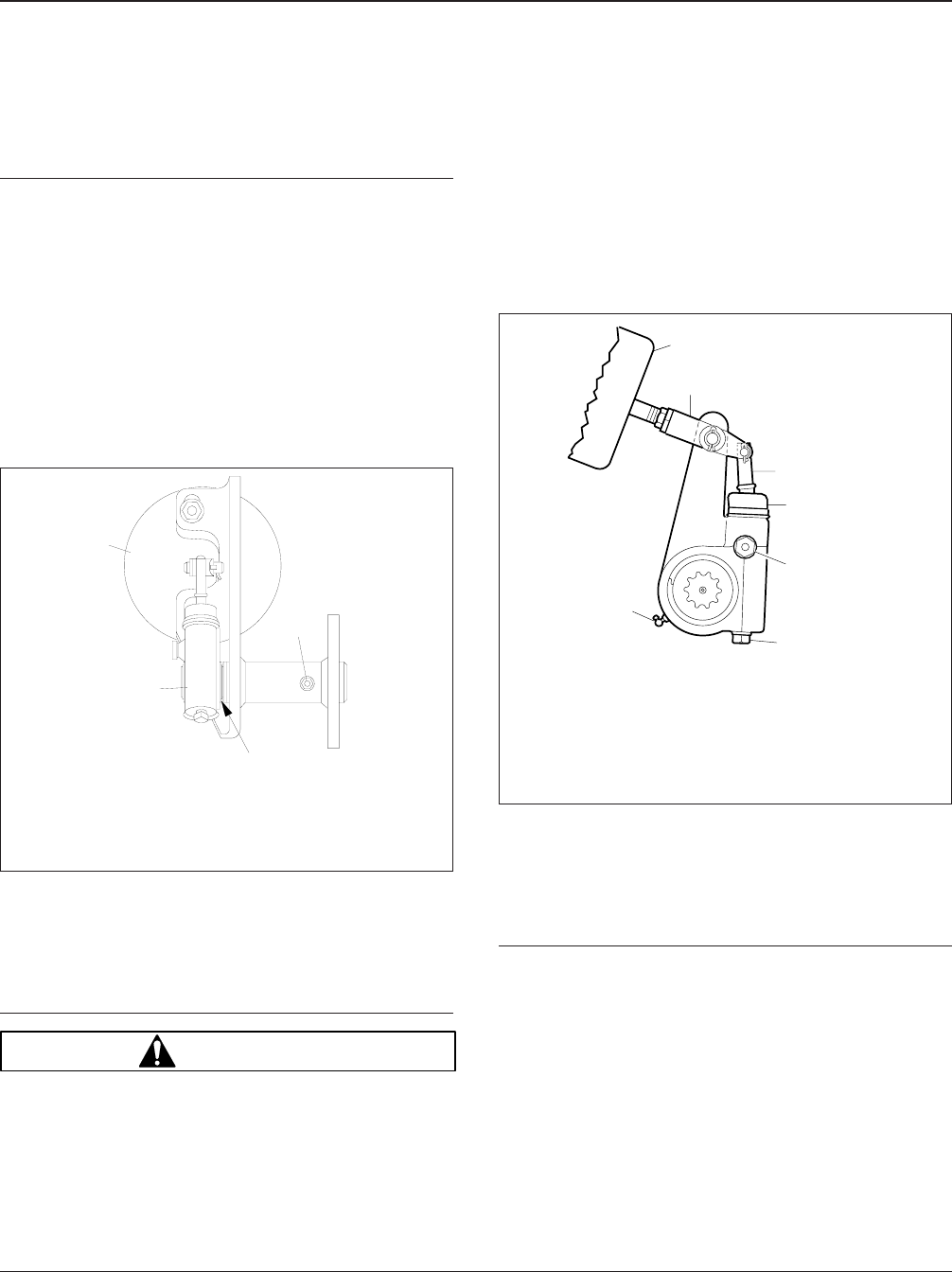

1. Inspect the slack adjuster for structural damage.

Replace the slack adjuster if needed.

2. Check the boot for cuts, tears, etc., and replace

it if necessary. See Fig. 5.

42–10 Automatic Slack

Adjuster Lubricating,

Meritor

IMPORTANT: Perform MOP 42–24 before lubri-

cating the slack adjusters.

Lubricate the slack adjuster using high-temperature,

waterproof grease NLGI Grade 1, Texaco Thermotex

EP 1, Shell Darina No. 1, Marathon 528 heavy-duty,

Sunaplex No. 1 EP, Amdex No. 1 EP, or Philube B

No. 1. It should be smooth-textured, corrosion-

resistant grease, free of fillers and abrasives.

f420011a

05/28/93

1

2

3

A

A. Grease exit.

1. Brake Chamber

2. Slack Adjuster

3. Grease Fitting

Fig. 4, Camshaft Bracket Bushing Lubrication

f420012a

10/20/93

1

2

3

4

5

6

7

1. Brake Chamber

2. Clevis

3. Actuator Rod

4. Boot

5. Pull-Pawl

6. Manual Adjusting Nut

7. Grease Fitting (or Lube Plug)

Fig. 5, Meritor Automatic Slack Adjuster

Brakes42

Acterra Maintenance Manual, October 200742/6