01–01 Engine-Support

Fasteners Checking

Front and rear engine supports for vehicles built from

January 2007 require no periodic maintenance.

Mounts should be inspected when the engine is re-

moved for service. For vehicles manufactured prior to

January 2007, perform the following check.

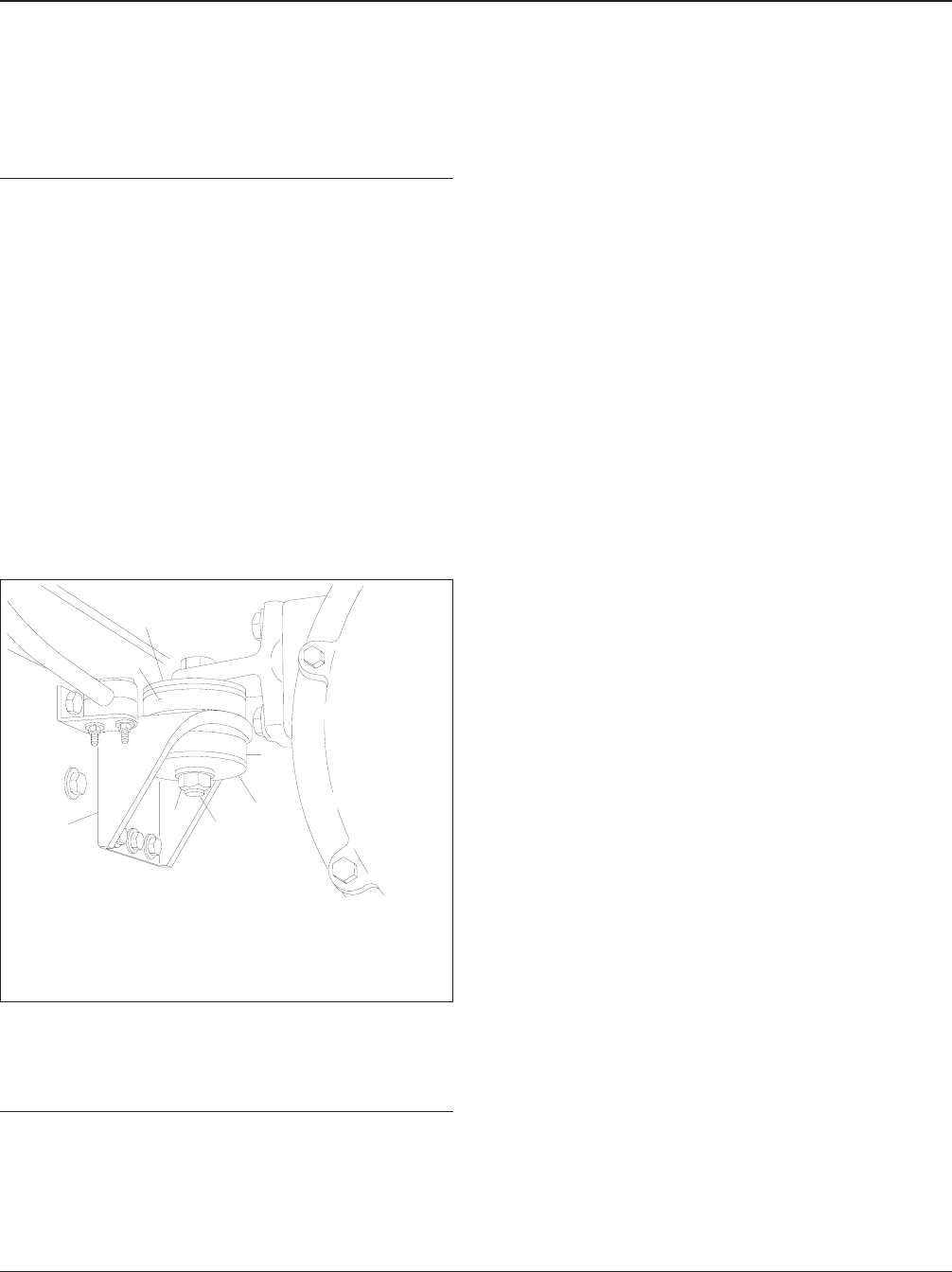

Check the rear engine-support fasteners (see Fig. 1,

Ref. 4) for tightness. Tighten the 3/4-inch fasteners

215 to 265 lbf·ft (292 to 359 N·m).

Check the front engine-support fasteners for tight-

ness. Tighten the 5/8-inch fasteners 125 lbf·ft (170

N·m).

NOTE: At engine overhaul, and whenever the

engine has been removed, inspect the lower

and upper isolators (Refs. 1 and 6), and replace

them if they are worn. See Group 01 of the

Acterra

®

Workshop Manual

for instructions.

01–02 Engine Drive Belt

Inspecting

Worn or loose drive belts may cause premature

bearing failure or engine overheating. Excessive ten-

sion, or too little tension on the belt may result in ex-

cessive and premature belt wear. Poly-V belts, or

serpentine belts, are retained by a belt tensioner that

requires no tension adjustment. Replace the engine

drive belt if any conditions described in the visual

description are found. V-belts are installed as indi-

vidual belts, and as matched sets. When replacing a

matched set of belts, always replace both belts at the

same time. Matched belts must be from the same

manufacturer. To inspect a belt, gently twist the belt

to view the belt sidewalls and bottom. Inspect all

drive belts for the following conditions, then perform

the belt tension inspection.

Belt Condition Inspection

1. Inspect the belt for glazing. See Fig. 2, Ref. A.

Glazing is represented by shiny sidewalls, and is

caused by friction created when a loose belt slips

in the pulleys. It can also be caused by oil or

grease contamination on the pulleys.

2. Check the belt for ply separation. See Fig. 2,

Ref. B. Oil, grease, or belt dressing can cause

the belt to fall apart in layers. Repair any oil or

coolant leaks that are affecting the belts before

replacing the drive belts. Do not use belt dress-

ing on any belt.

3. Check the belt for a jagged or streaked sidewall.

See Fig. 2, Ref. C. Jagged or streaked sidewalls

are the result of foreign objects, such as sand or

gravel in the pulley, or a rough pulley surface.

4. Check for tensile breaks (breaks in the cord

body). See Fig. 2, Ref. D. Cuts in a belt are usu-

ally caused by foreign objects in the pulley, or by

prying or forcing the belt during removal or instal-

lation.

5. Check for uneven ribs on serpentine (poly-V)

belts. See Fig. 2, Ref. E. Foreign objects in the

pulley will erode the undercord ribs, causing the

belt to lose its gripping power.

6. Check the drive belts for cracks. See Fig. 2, Ref.

F. Small irregular cracks are usually the signs of

an old belt.

7. Inspect the pulleys for excessive play or wobble.

Excessive play or wobble indicates a failure of

the pulley bearing. Check for belt squealing or

squeaking. Replace the bearings as necessary.

NOTE: If it is difficult to distinguish the location

of a supposed bearing noise, obtain a stetho-

scope and place it on the component being

f220047a

1

2

3

4

5

6

2

10/05/94

1. Lower Isolator

2. Engine Support

Washer

3. 3/4–10 Capscrew

4. 3/4–10 Hexnut

5. Engine Mount

6. Upper Isolator

Fig. 1, Engine Rear Mount

Engine 01

Acterra Maintenance Manual, January 2007 01/1