fected component must be thoroughly drained.

Switching to a synthetic lubricant, when a

petroleum-based lubricant has been used for

50,000 miles (80 000 km) or longer, may affect

transmission performance. Monitor all seal

areas for the first 10,000 miles (16 000 km)

after changing to a synthetic from a petroleum-

based lubricant.

NOTE: The correct fluid capacity is established

by the fill plug opening.

2. Clean the fill plug, then install it in the transmis-

sion. Tighten the plug as follows:

• 25 to 35 lbf·ft (34 to 48 N·m) for Eaton

Fuller transmissions with 3/4-inch pipe

threads.

• 60 to 75 lbf·ft (81 to 102 N·m) for Eaton

Fuller transmissions with 1-1/4-inch pipe

threads.

26–03 Allison Transmission

Breather Checking

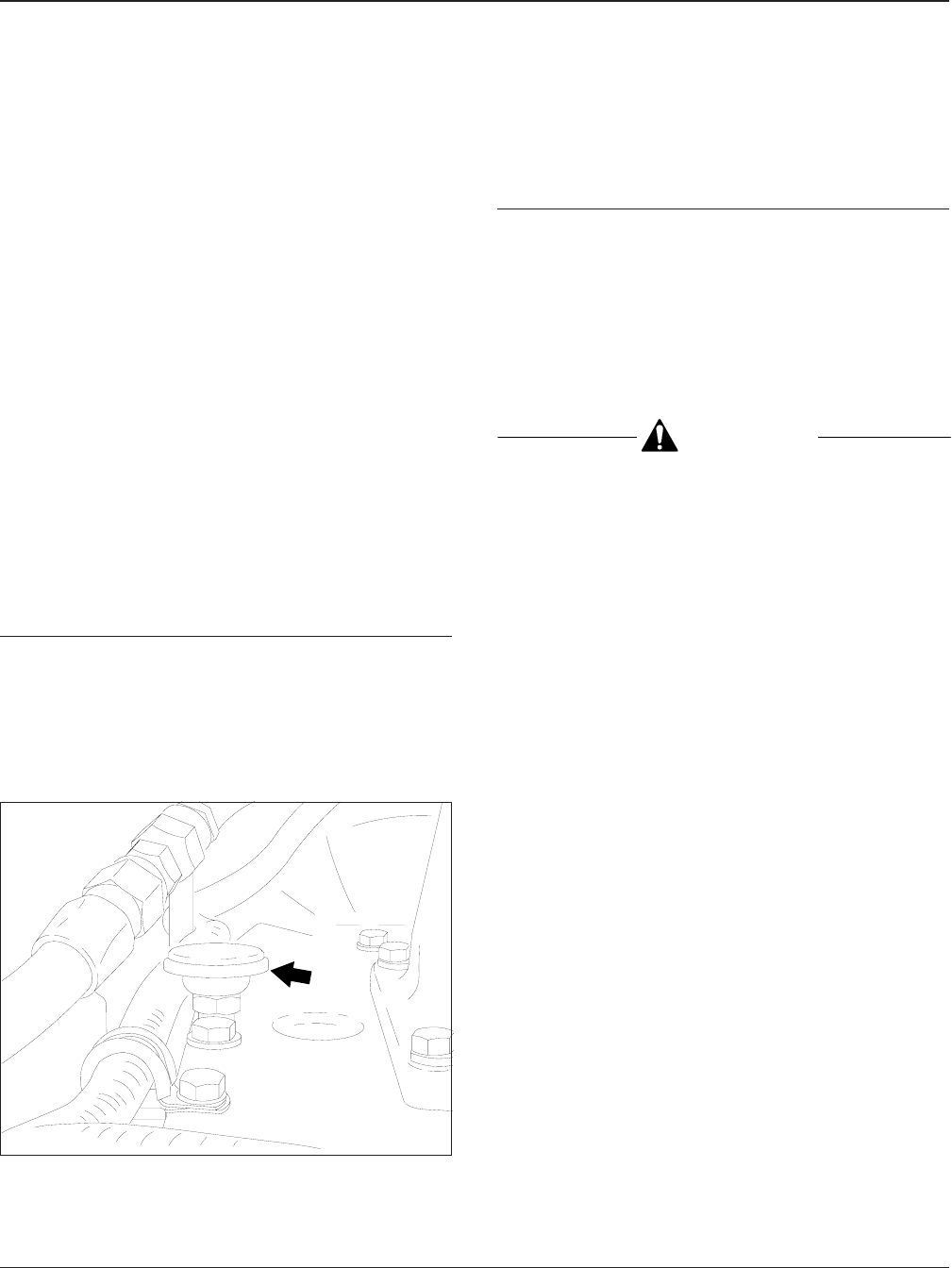

Transmission housing breathers must remain clear. A

plugged breather could result in pressure build-up,

which could cause fluid leakage.

If the breather is plugged, clean or replace it. See

Fig. 2. Check more often if the vehicle is operating

under very dusty conditions.

26–04 Allison Transmission

Fluid and Filter

Changing

1000/2000/2400 Series

1. Park the vehicle on a level surface and apply the

parking brakes.

2. Run the engine until the transmission fluid

reaches the operating temperature of 160 to

200°F (71 to 93°C). Shift the transmission to

neutral (N) and shut down the engine.

CAUTION

To prevent dirt from entering the transmission,

use only clean containers and fillers for the trans-

mission fluid. Do not use fillers or containers that

have been used for water or antifreeze. Dirt, water,

or antifreeze could damage the transmission.

3. Clean the area around the drain plug. Place a

drain pan under the transmission and remove the

drain plug. Examine the fluid while it drains. If

only the filter is being changed, do not drain the

fluid.

NOTE: A lot of fluid will drain when the filter is

removed.

4. Using a standard strap-type filter wrench, remove

the filter by turning it counterclockwise.

5. Remove the magnet from the filter attachment

tube or from the top of the filter element.

6. Clean any metal debris from the magnet. Then,

install the magnet on the filter attachment tube.

7. Using transmission fluid, lubricate the gasket on

the filter.

8. Using your hand, install the filter by turning it

clockwise until the filter gasket contacts the con-

verter housing or cooler manifold. Then, turn the

filter one more complete turn.

9. Install the drain plug and sealing washer. Tighten

the plug 22 to 30 lbf·ft (30 to 40 N·m).

10. Clean the area around the fill tube and remove

the dipstick. Using a clean funnel in the fill tube,

add transmission fluid. See Table 3 for approved

transmission lubricants, and Table 4 for lubricant

capacities.

f260007a

05/27/93

Fig. 2, Transmission Breather

Transmission 26

Acterra Maintenance Manual, March 2005 26/3