Hendrickson Spring-Eye Pins,

RT and RTE Series

NOTE: See Fig. 7 for this procedure.

Apply multipurpose chassis grease at the spring eye

pin grease fitting (located on the inboard side of the

spring eye pin) until clean grease appears at both

ends of the spring eye pin.

Freightliner TufTrac

The TufTrac suspension is maintenance-free and de-

signed so that lubrication is not required. There are

no provisions for lubrication and attempting to lubri-

cate the suspension could shorten component life.

32–03 U-Bolt Torque Checking

Check the U-bolt torque of both the front and rear

axles (where applicable).

CAUTION

Failure to retorque the U-bolt nuts could result in

spring breakage and abnormal tire wear.

1. Park the vehicle on a flat surface and apply the

parking brakes. Chock the tires to prevent the

vehicle from moving.

2. Check the U-bolt torque in a diagonal pattern.

Set a click-type torque wrench to the highest

torque value for the fastener being checked. See

Table 1 for U-bolt torque specifications. Turn the

wrench in a clockwise motion (looking up) until

the torque wrench clicks.

3. Remove the chocks.

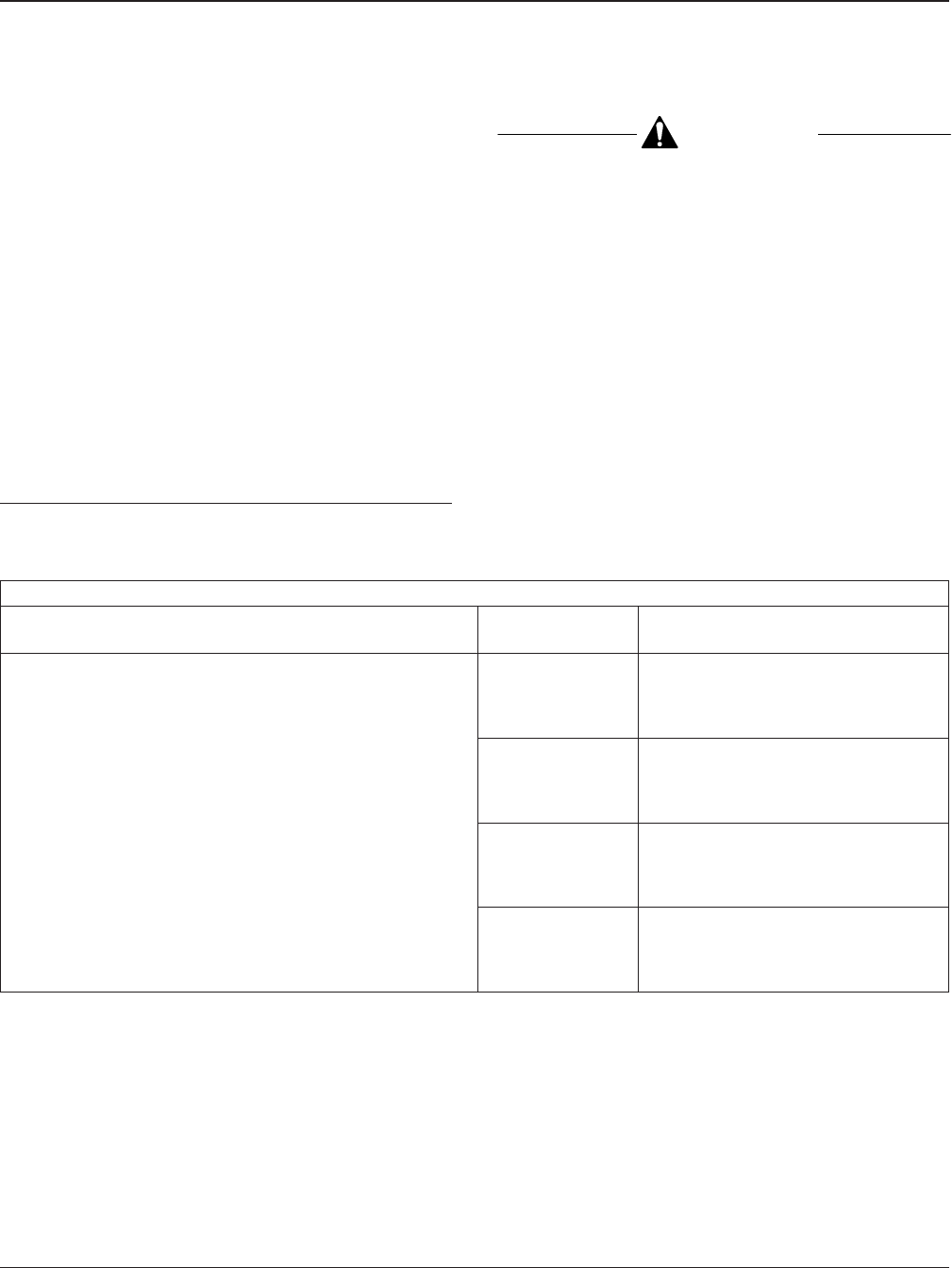

U-Bolt Torque Values

Description Size

Torque:

lbf·ft (N·m)

Spring Assembly U-Bolt High Nuts

*

5/8–18

Stage 1: Hand Tighten

Stage 2: 60 (81)

Stage 3: 200 (271)

Stage 4: 180 to 230 (245 to 313)

3/4–16

Stage 1: Hand Tighten

Stage 2: 60 (81)

Stage 3: 200 (271)

Stage 4: 270 to 330 (367 to 449)

7/8–14

Stage 1: Hand Tighten

Stage 2: 60 (81)

Stage 3: 200 (271)

Stage 4: 420 to 500 (571 to 680)

1–14

Stage 1: Hand tighten

Stage 2: 60 (81)

Stage 3: 200 (271)

Stage 4: 520 to 600 (707 to 816)

*

Tighten in a diagonal pattern as shown in Fig. 12.

Table 1, U-Bolt Torque Values

Suspension 32

Acterra Maintenance Manual, September 2002 32/9