• 1-1/8–12, 350 to 650 lbf·ft (475 to 881

N·m)

• 1-1/4–12, 500 to 675 lbf·ft (678 to 915

N·m)

10. Check the steering arm bolts for a minimum

torque of 300 lbf·ft (406 N·m). If the steering arm

bolt torque has fallen below this specification,

remove the bolt, clean all the threads, and apply

new Loctite

®

680. Tighten the bolt 300 to 450

lbf·ft (406 to 610 N·m).

11. Remove the chocks from the tires.

33–03 Tie Rod End Lubricating

This procedure applies to all tie rod ends on Meritor

nondrive steering axles.

1. Park the vehicle with the wheels in the straight-

ahead position. Turn off the engine, apply the

brakes and chock the rear tires.

2. Wipe the zerk fitting and the seal or boot clean.

NOTE: Synthetic lubricants are not approved for

tie rod end lubrication.

3. Using a grease gun, apply a multipurpose

grease, NLGI grade 1 or 2, to the zerk fitting until

all the old grease is purged from the boot. Dis-

colored old grease should come out of the purge

holes near the boot crimp or bellows area.

Apply grease until all the old grease is purged

from the boot.

NOTE: If using an air pressure grease gun, do

not exceed 150 psi (1035 kPa).

4. If the tie rod end is designed for lube service and

it does not accept grease, perform the following

substeps.

4.1 Remove the zerk fitting.

4.2 Inspect the threaded zerk fitting hole in

the tie rod end and remove any obstruc-

tions.

4.3 Install a new zerk fitting.

4.4 Apply lubrication to the new zerk fitting.

5. Remove the chocks from the tires.

33–04 All-Axle Alignment

Checking

Drive Axle Alignment Checking

Check the axle alignment, parallelism, and thrust

angle measurements for the rear drive axles. Use the

applicable procedure and specifications in Group 35

of the

Acterra

®

Workshop Manual

.

Toe-In Checking, Front Axle

See Group 33 of the

Acterra

®

Workshop Manual

for

wheel alignment procedures.

33–05 All-Wheel-Drive Front

Axle Oil Level Checking

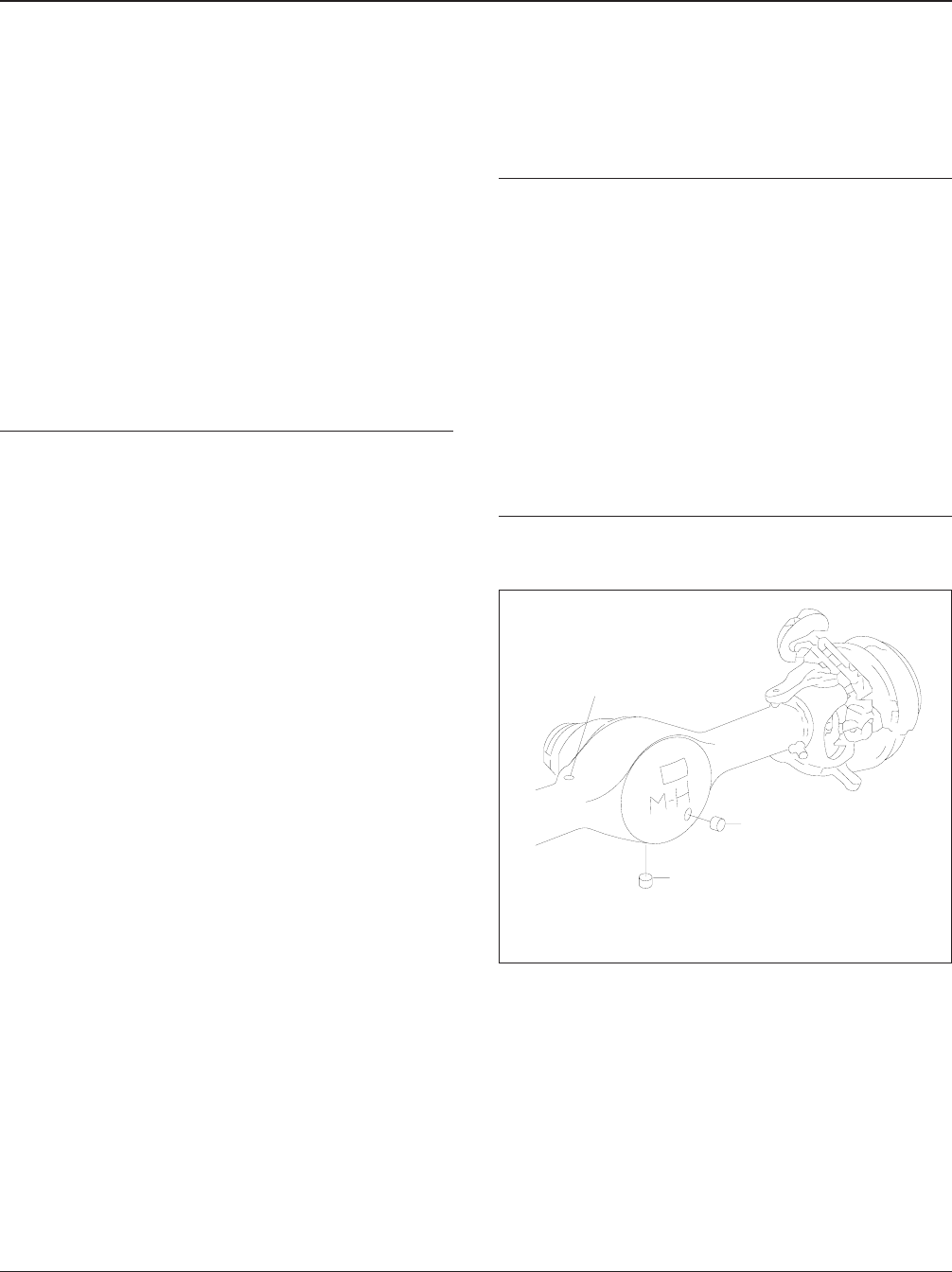

1. On all front-wheel-drive vehicles, check the oil

level in the differential. See Fig. 6.

1.1 Remove the oil level check-and-fill plug,

and make sure the oil level is even with

the bottom of the bore.

1.2 If needed, add oil until the differential is

filled to the bottom of the bore.

1.3 Install the oil level check-and-fill plug, and

tighten it firmly.

04/15/96

f350149

1

2

3

1. Vent Valve

2. Oil Level Check-and-Fill Plug

3. Oil Drain Plug

Fig. 6, All-Wheel-Drive Front Axle Differential

Front Axle33

Acterra Maintenance Manual, September 200233/4