1. Shut off the engine, apply the brakes, and chock

the rear tires.

2. Check the tie rod boot for cracks, tears, or other

damage. If the tie rod boot is damaged, replace

the entire tie rod end.

3. Grasp by hand (or use a pipe wrench with jaw

protectors to avoid gouging the cross tube) and

slightly rotate the cross tube toward the front of

the vehicle and then slightly toward the rear.

Then center the cross tube between the stop po-

sitions. If the cross tube does not rotate in either

direction, replace both tie rod ends.

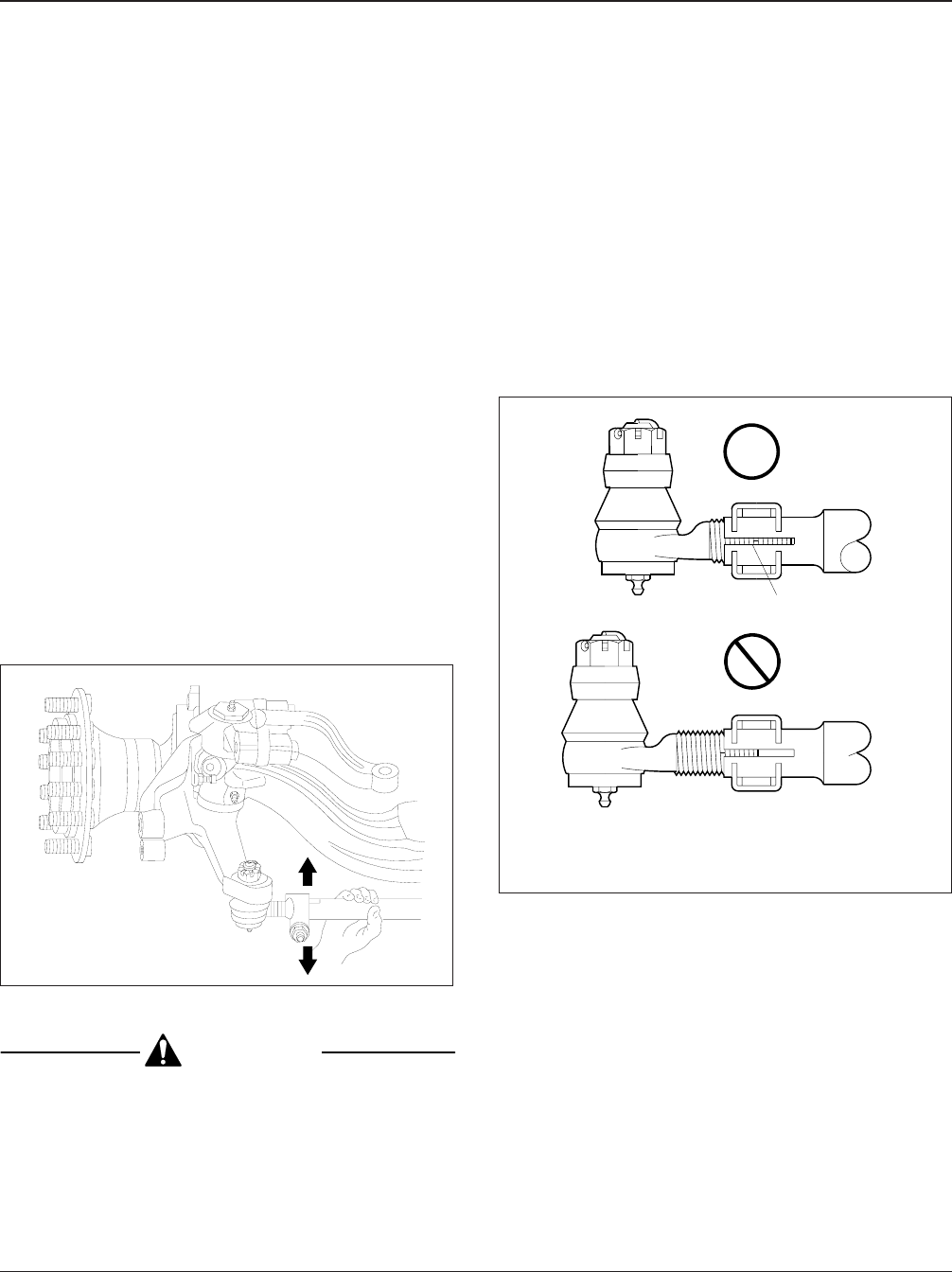

4. Position yourself directly below the ball stud

socket. Using both hands, grab the end as close

to the socket as possible, no more than 6 inches

(15.2 cm) from the end. Firmly apply about 100

pounds of hand pressure in an up and down mo-

tion several times. When moving the assembly,

check for any movement at both tie rod ends.

See Fig. 4.

If any movement is detected at one tie rod end,

replace both tie rod ends. Always replace tie rod

ends in pairs, even if only one tie rod end is

damaged.

CAUTION

Do not attempt to straighten a bent cross tube.

Doing so could result in damage to the axle. Be

sure to replace the cross tube with an original

equipment cross tube with the same length, diam-

eter, and thread size as the existing cross tube.

5. Check the cross tube for cracks or other dam-

age. If the cross tube is bent or damaged, re-

place the cross tube.

6. Check the clamps for damage. If a clamp is

damaged, replace the clamp. Replace the entire

cross tube assembly if either clamp is welded to

the cross tube.

7. Check for proper installation of the tie rod end

clamp to the cross tube. Make sure that the tie

rod ends are threaded in the cross tube past the

clamps and the slots at the cross tube ends. See

Fig. 5.

8. Check the zerk fittings for damage. If a zerk fit-

ting is damaged, replace it.

Some tie rod ends have no zerk fittings because

they are not to be greased. Do not install a zerk

fitting on this type of tie rod end.

9. Check that the cotter pin is in place. If it is not,

tighten the tie rod end nut to one of the following

specs depending on the size of the stud.

• 7/8–14, 160 to 300 lbf·ft (217 to 406 N·m)

• 1–14, 250 to 450 lbf·ft (339 to 610 N·m)

10/10/2001

f330195

Fig. 4, Check Movement of Tie Rod End

f320033a

1

OK

OK

02/27/2007

NOTE: Pinch bolt not shown to provide clarity.

1. Cross-Tube Split

Fig. 5, Tie-Rod End Adjustment

Front Axle 33

Acterra Maintenance Manual, September 2002 33/3